08_David Trueman

advertisement

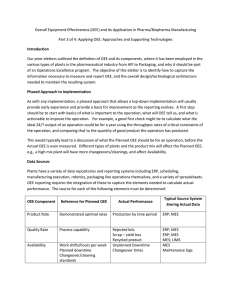

PERFORMANCE ANALYSIS AND BENCHMARKING FOR BULK OPERATIONS David Trueman David.trueman@dbis.biz 00 44 7785 707483 Key Performance Indicators Almost all businesses use KPIs in some form to measure their performance The simplest (and most important) measure of performance for most businesses is the Profit and Loss sheet in the annual accounts Operational Performance Most managers understand how their Terminal operates and what constitutes good practice and performance This is often based upon rule of thumb, historical experience or the assumption that “everyone is doing their best and nobody is complaining” Why Use KPIs? Source: AberdeenGroup, March 2006 Pressure to improve operational performance 67% Competitive advantage in price and service 45% Customers demanding shorter order cycle time 44% Customers demanding reduced prices 34% Corporate objective to reduce inventory 29% Pressure to improve return-on-invested-capital 26% Increase product quality 0% 23% 20% 40% 60% 80% 100% Making KPIs Effective 5 For KPIs to be effective they need to reflect the goals of the business It is rarely about financial metrics, KPIs are a communication and steering mechanism for management to bring about operational improvements through shared goals KPI characteristics: » » » » » » » A KPI should echo an organisational goal It should be decided by management It creates understanding on all organisational levels It is based on real data It should be easy to understand It should lead to action It should improve performance Take action to improve performance Map Impacts and set priorities Understand the results Chose indicators and understand data needs Evaluate the product Assess the operations Measure inputs used in operations Measure Good and Bad Data 6 Bad Data Source Good Data Source Just because Excel is good for manipulating data it doesn’t make it a good KPI tool. It is about where the data came from and how Using Bad Data Leads to Failure Hand Written or Spread Sheet Shift Reports/Tally Sheets have been found to be almost always inaccurate because: Data (information) is often written after the fact with incorrect times/quantities Root cause can be anecdotal (the circuit breaker tripped rather than what caused it to trip) The writer edits the data to reflect what they want others to see rather than what happened (hatch change took five minutes but a simultaneous tea break took ten) If data is too difficult to collect it becomes a chore and is less likely to be sustainable or accurate Good Data and How To Get It 8 Typical Real Time Data Sources are the Way Forward » » » » » » TOS Automation Weighing ERP 3rd Party Android DATA DATA DATA Data automatically collated – little / no manual entry • Eliminates user error and provides fast accurate data ANALYSIS ANALYSIS Real time KPI’s • Always on and never out of date REVIEW REVIEW ACTION System Based Processing and Data Mining • Fact based decision making • ‘One version of the truth’ Ideal ACTION Too much time before Analysis and Review Causes disconnected Action System Based Analysis and Review allows for Connected and Effective Action Operational Dashboards Based on Real Time Data The screen here provides users with a real time view of the vessel discharge based on data from weighing and automation systems: Monitoring Vessel Discharge Against Contract Terms Here the data is collated with the contractual terms to provide a real time view of performance: Using Accurate Data Stoppages KPI Reports Vessel Information KPI Reports Vessel Information KPI Reports Overall Equipment Effectiveness Berth Plans and Forecasts Stock Forecasts KPI Reports Space Availability KPI Reports Terminal Throughput KPI Reports Feed Rates KPI Reports Time In Store KPI Reports Road Vehicle Statistics Benchmarking The container business has recognised the benefits of industry benchmarking and data is readily available to allow terminal operators to compare themselves with industry standards The bulk industry appears to be reluctant to share information to allow performance benchmarks to be established An initiative by the Dry Bulk Terminals Group to establish Overall Equipment Effectiveness as a global benchmark was poorly received by members even though the findings of a trial by five terminals proved successful. It is good to see that the group have reassumed a benchmarking initiative at their latest meetings, however it appears that nervousness regarding the sharing of data may override the prospective benefits for the industry Multi-Industry benchmarks such as OEE are globally accepted standards for operational and manufacturing excellence because of their consistency. OEE is a reliable comparison of performance no matter how different the processes or activities and the industry and all stakeholders would benefit from the improvements that would be derived. How OEE can Improve a Business and Our Industry OEE is an industry wide standard for measuring and continuously improving operational performance By using consistent measurement of reliable data performance can be analysed, best practice identified and improvements implemented How to derive OEE? Schematic representation of impact of losses on Plant Performance Total Planned Plant Operating Time Breakdowns, Setup Adjustments Actual Production Time Small Stops, Reduced Speed Net Production Time Valuable Production Time Industrial Automation Practice Frost & Sullivan, 2005 Startup & Production Rejects 6 Key Losses Planned Shutdown Planned Production Time What does improving OEE mean? Improving the effectiveness of your operation Improve Availability >> Less downtime >> more production time Improve Performance >> Improved capability >> higher sustainable rates Sustained production flow Lower consumables consumption (energy) Avoid capital investment >> Lower bottom line cost OEE for Vessel Discharge The OEE Calculation is: Actual Availability X Productivity (TPH Achieved) = OEE Planned Availability Maximum Equipment Capability Example In theory, at 60% occupancy, this would create the capacity to discharge an additional 528,666 tonnes per year. If the profit on discharging vessels was 50 cents per tonne this would generate $264.333.00 in additional profit This is theoretical but the principle is clear; small incremental performance improvements can radically improve the bottom line of the business Conclusion Using KPIs in Bulk Terminals allows operators to create an environment of continuous improvement Small gains in productivity or space utilisation can create large improvements to the financial bottom line KPIs are only effective if the data is easily available, consistent and believable OEE is a trans-industry benchmark providing consistent comparisons regardless of differences in process Industry standard benchmarking would help drive improvements across the industry and provide guidelines for new terminals in developing markets Thank you DBIS (Software and Automation) Ltd CommTrac Terminal Management www.dbis.biz