Aggregate Planning, MRP, and Short Term Scheduling

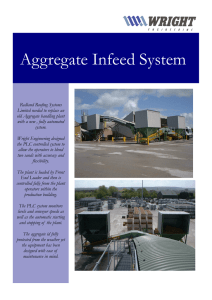

advertisement

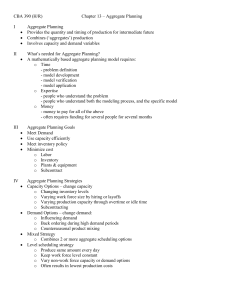

Aggregate Planning, MRP, and Short Term Scheduling Introduction What – Determine the quantity and timing of production for the immediate future Where – To meet forecasted demand Why – Minimize costs The Planning Process Aggregate planning ties strategic goals to production plans Medium range – 3 to 18 months Requires: Measure of sales and output Forecast of demand for the period Method of determining costs Model that combines forecasts and costs Aggregate Plan Relationships Marketing Customer Demand Production Capacity Inventory Procurement Supplier Performance Finance Cash Flow Aggregate Production Plan Management Return on Investment Capital Engineering Design Completion Human Resources Manpower Planning Capacity Options Change inventory levels Change workforce size Change production rates Subcontracting Using Part-Time Workers Demand Options Influence demand Back order during high demand periods Counterseasonal product mix Strategies Chase strategy Level strategy Mixed strategy Aggregate Planning Problems The Transportation Model of linear programming is a form of Aggregate Planning Compare different strategies Tabulate costs of the plan over a period of time