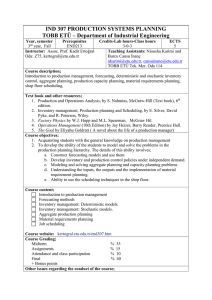

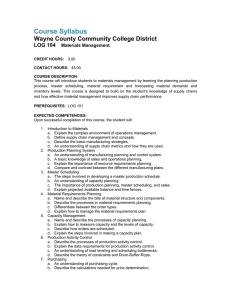

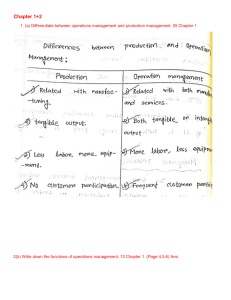

MENG 445: Production and Inventory Control (3 credits) Elective Coordinator: Lotfi K. Gaafar, Associate Professor, Fulltime. e-mail: gaafar@aucegypt.edu Course (catalog) description: Basic concepts of production management; forecasting; break-even analysis, aggregate production planning; inventory management; master scheduling, materials requirement planning; capacity planning; resource allocation and scheduling. Hours: three 1-hour class periods. Prerequisite: ENGR 313 and 345. Textbook: Stevenson, William, J. Operations Management, McGraw-Hill, eighth edition, 2005. Course Goals: This course focuses on the operation and control of productive systems. The goals of the course are: 1. To increase the student understanding of the problems and opportunities faced by the operations manager in manufacturing and service organizations. 2. To develop the student ability to apply operations management concepts in a variety of settings. 3. To develop the student understanding of operations management techniques in order to be able to evaluate recommendations made by technical specialist in the field. Course Outcomes: After completing the course, students will be able to: 1. Determine the key aspects of operations management decision-making. 2. Apply cost, volume, profit analysis techniques in determining production volume and mix. 3. Use the moving average, exponential smoothing, and regression analysis to develop forecasts, and measure the accuracy of the forecast. Develop forecasts based on time series analysis. 4. Identify the variables decision makers have to work with in aggregate planning and the various strategies they can use. 5. Use the EOQ model, the economic run size model, the quantity discount model, the reorder point models in various inventory management decision making situations. 6. Translating how requirements in a master production schedule into material requirements for lower level items. 7. Scheduling and sequencing of manufacturing operations and measuring shop performance. 8. Use quantitative techniques in scheduling in both manufacturing and service environments. 9. Utilize existing software to solve forecasting and aggregate planning problems. Computer Usage: Students will use Microsoft Excel to solve forecasting, and aggregate planning problems. Topics: • • • • • • • • Introduction: Production/Operations Management Forecasting Aggregate Planning Inventory Management Material Requirements Planning (MRP) Just-In-Time Production Short-term Scheduling Tactics Supply Chain Management Course contribution to meeting professional component: Mathematics or basic science 1 cr. Engineering science 2 cr.