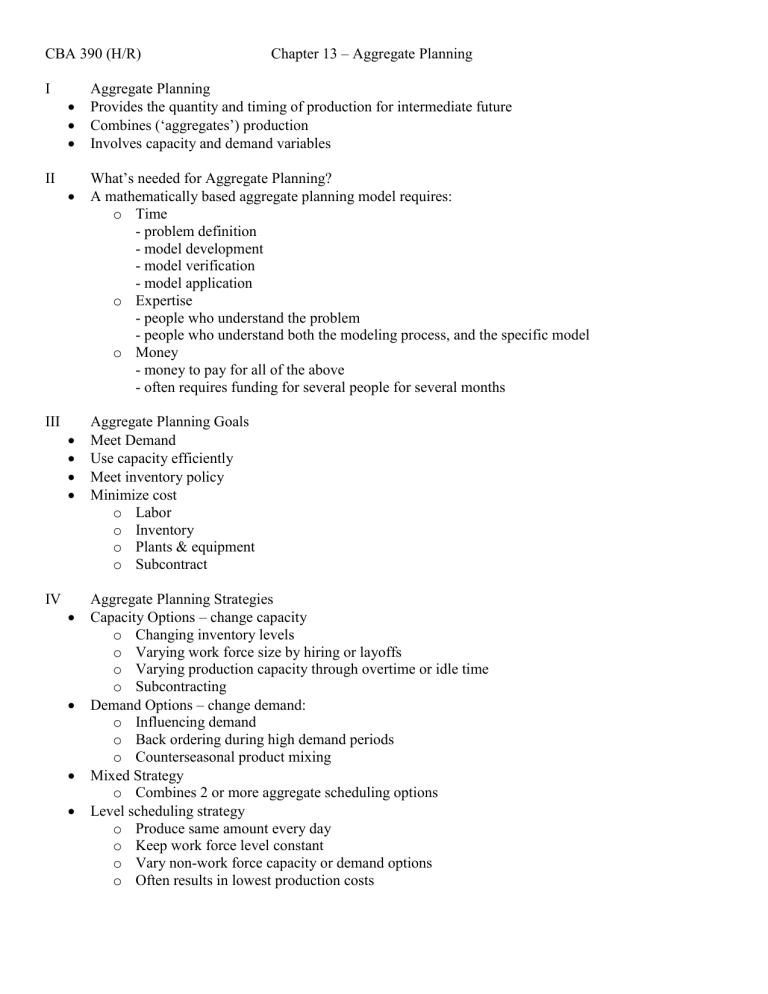

CBA 390 (H/R) Chapter 13 – Aggregate Planning I

CBA 390 (H/R)

I

Chapter 13 – Aggregate Planning

Aggregate Planning

Provides the quantity and timing of production for intermediate future

Combines (‘aggregates’) production

Involves capacity and demand variables

II

What’s needed for Aggregate Planning?

A mathematically based aggregate planning model requires: o Time

- problem definition

- model development

- model verification

- model application o Expertise

- people who understand the problem

- people who understand both the modeling process, and the specific model o Money

- money to pay for all of the above

- often requires funding for several people for several months

III Aggregate Planning Goals

Meet Demand

Use capacity efficiently

Meet inventory policy

Minimize cost o Labor o Inventory o Plants & equipment o Subcontract

IV Aggregate Planning Strategies

Capacity Options – change capacity o Changing inventory levels o Varying work force size by hiring or layoffs o Varying production capacity through overtime or idle time o Subcontracting

Demand Options – change demand: o Influencing demand o Back ordering during high demand periods o Counterseasonal product mixing

Mixed Strategy o Combines 2 or more aggregate scheduling options

Level scheduling strategy o Produce same amount every day o Keep work force level constant o Vary non-work force capacity or demand options o Often results in lowest production costs

V Aggregate Planning Methods

Graphical and charting techniques o Popular and easy-to-understand o Trial and error approach

Mathematical approaches o Transportation method o Linear decision rule o Management coefficient model o Simulation

VI Yield Management