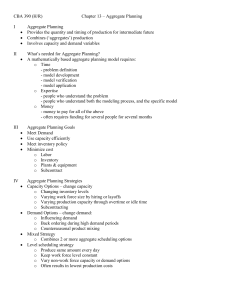

OM 4600 Notes Week of September 16, 1996

advertisement

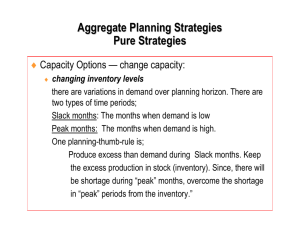

MGMT250 Notes November 12, 2002 Schedule and Announcements 1. Next week we go to Polar Beverages. Leave here at 8:15, tour at 8:30. 2. Go Over Forecasting Homework. 3. Begin Aggregate Planning, Next class begin looking at Agg Planning Tools. 2. Let us take a look at H.W. 3. Aggregate Planning - The planning of resources and rates for product groups and broad categories (versus individual products and services). The aggregate plan specifies the combination of production rate, work-force level, and inventory requirements, among other factors for producing goods or services. The role of aggregate planning fits within strategic and operational planning. Usually a 4-18 month planning horizon. Capacity and Process planning are major inputs, master production schedules are outputs. Strategies for aggregate planning (demand and supply strategies): Demand Strategies - Usually within the domain of marketing. Carry out promotions and vary pricing to meet production levels. Another example is finding complementary products to help demand become more level (example of a complementary product?) Supply Strategies: The role of aggregate planning and operations management plays a role here. Example strategies include (see graphic): 1. Chase Demand Strategy: Match production rate to the demand rate. Good for inventory management, bad for volatility in system. 2. Level Production Strategy: Keep production levels constant. Higher inventory, stock out problems, less volatility in system. 3. Hybrid Strategies - Mixture of chase and level strategies. To determine best aggregate planning strategy for organization must consider a number of costs for resources. These costs include: 1. Basic Production Costs - Direct/Indirect Labor costs, Overtime Costs. 2. Volatility Costs - Hiring/Firing/Idle Time costs. 3. Inventory Costs - Most of holding costs. 4. Stock-Out (Shortage or Back Logging Costs): Expediting, loss of goodwill, lost sales revenue, etc. Material Balance Equation is central to a number of models: Demand in this Period (Dt) = Regular Time Production (Rt) + Overtime Production (Ot) + Subcontracted Production (SCt) + Inventory from last Period (It-1) - Inventory stored in this Period (It) - Backorders from last Period (Bt-1) + Backorders in this Period (Bt). Or: Dt = Rt + Ot + SCt +It-1 - It - Bt-1 + Bt Tools: There are a number of tools available to the aggregate planner including: Trial and Error/Spreadsheet and Transportation Tableau approaches. We will take a look at each. Next Class.