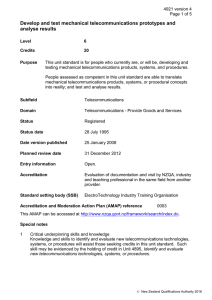

Manufacture telecommunications components

4983 version 4

Page 1 of 4

Manufacture telecommunications components

Level 4

Credits 10

Purpose This unit standard is for people who are currently, or will be, manufacturing telecommunication components.

People assessed as competent in this unit standard are able to confirm the performance of manufacturing materials, manufacture components, and ensure manufactured components are reliable.

Subfield Telecommunications

Domain

Status

Status date

Date version published

Telecommunications - Provide Goods and Services

Registered

28 July 1995

25 January 2008

Planned review date

Entry information

31 December 2012

Open.

Accreditation Evaluation of documentation and visit by NZQA and industry.

Standard setting body (SSB) ElectroTechnology Industry Training Organisation

Accreditation and Moderation Action Plan (AMAP) reference 0003

This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do

.

Special notes

General Range

Telecommunications components : electrical transformers, coils, electronic transistors, integrated circuits, resistors, capacitors, Eproms, radio components, cases, knobs, racks, bare circuit boards, masked and unmasked software.

New Zealand Qualifications Authority 2020

4983 version 4

Page 2 of 4

Elements and performance criteria

Element 1

Confirm performance range of materials used in manufacturing telecommunications components.

Performance criteria

1.1

Materials used to manufacture telecommunications components comply with design specifications and relevant industry standards.

Range materials

– plastics, wiring, metals, fibres, other materials required in the manufacturing process; design specifications flammability, toxicity, shelf life, electrostatic, temperature, humidity, altitude and gravity storage requirements, mean time before failure, physical characteristics, input and output characteristics, performance range, stability, reliability, high voltage discharge, flashover, material safety, cost range; industry standards

– including Deutsche Industrie Norm, Institute for Interconnecting and Packaging Electronic Circuits,

Iinternational European Community, British, Australian and New

Zealand standards, MILSPEC (Military Specification), Eurolab,

Hewlett-Packard.

1.2

Test records confirm performance of manufacturing materials and are accurate, complete, and available to authorised users.

Range authorised users – personnel responsible for the manufacturing of telecommunications components, management, technical specialists, other authorised personnel.

Element 2

Manufacture components.

Performance criteria

2.1

Authorised work instructions are identified and are accurate and complete.

2.2

Sequence of manufacturing processes complies with authorised work instructions.

Range cutting, drilling, moulding, heat treatments, plating.

2.3

Manufacturing process controls are identified, comply with work instructions, and are available immediately from the agreed place.

Range raw material input, processing equipment and material temperature, cycle time, electric settings, variability.

New Zealand Qualifications Authority 2020

4983 version 4

Page 3 of 4

2.4

Process control checks are completed by the agreed time, and results are documented in the agreed format.

2.5

Results from completed process control checks are consistent with work instruction requirements.

2.6

Variations to manufacturing processes are authorised by accountable manager, are documented, and comply with agreed organisational procedures.

Range variations – from work instructions; manufacturing process

– work instructions, process sequence, process parameters; accountable manager – with line or budget responsibility.

Element 3

Test manufactured telecommunications components.

Performance criteria

3.1

Test methodologies for manufactured telecommunications components are identified and are accurate and complete.

Range level of testing and sampling required in relation to standard test procedures, intended use, consequence of failure, cost of testing, cost per manufactured unit, practicality.

3.2

Manufactured telecommunications components are tested by the agreed time, comply with test requirements, and results are recorded.

Range test requirements

– test levels: in line, external, sample, destructive, non-destructive, test sampling, procedures.

3.3

Tested manufactured components display agreed test status, or certificates specifying test conformance are available on request.

Range test or quality control record including identifier of person responsible for the test.

3.4

Test results for manufactured telecommunications components are filed and are available to authorised personnel.

Range authorised personnel – production supervisors, management, customers, other authorised personnel with need to have access to records.

Please note

Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

New Zealand Qualifications Authority 2020

4983 version 4

Page 4 of 4

Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards.

Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards.

Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The

AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact the ElectroTechnology Industry Training Organisation reviewcomments@etito.co.nz

if you wish to suggest changes to the content of this unit standard.

New Zealand Qualifications Authority 2020