Create and maintain telecommunications production schedules

advertisement

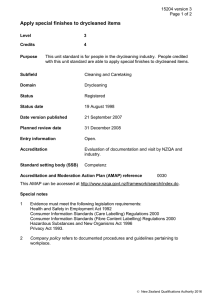

4896 version 4 Page 1 of 3 Create and maintain telecommunications production schedules Level 4 Credits 4 Purpose This unit standard is for people who currently are, or will be, working in a manufacturing environment and creating production schedules. People assessed as competent in this unit standard are able to create schedules for gathered information, and maintain schedules to ensure production of telecommunications goods and services is by the agreed time. Subfield Telecommunications Domain Telecommunications - Provide Goods and Services Status Registered Status date 28 July 1995 Date version published 25 January 2008 Planned review date 31 December 2012 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) ElectroTechnology Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0003 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes None. New Zealand Qualifications Authority 2016 4896 version 4 Page 2 of 3 Elements and performance criteria Element 1 Create production schedules. Performance criteria 1.1 Production requirements are identified from customer orders and in-house forecasts. Range 1.2 Draft production schedule is determined from identified production requirements, raw material stock levels, lead times, and manufacturing capacity. Range 1.3 materials, code numbers, supplier's references, including supply dates. Anticipated constraints to production schedule are identified and contingencies are developed, agreed, and implemented when required to optimise production performance. Range 1.6 management, head of production, sales and marketing, other relevant parties affected by production schedule. Requisitions for identified material requirements are received by authorised purchasing personnel by the agreed time. Range 1.5 includes material requirements, completion dates, and delivery response times; labour, materials, machinery, time. Draft production schedule is agreed with relevant authorised personnel prior to development of master production schedule. Range 1.4 products, volumes, quantities, delivery dates. material shortages, outages, raw materials out of specification, resources, power failures, delivery problems. Master production schedule is current, accurate, complete and available to authorised personnel by the agreed time. Range management, production staff. New Zealand Qualifications Authority 2016 4896 version 4 Page 3 of 3 Element 2 Monitor and maintain production schedules. Performance criteria 2.1 Variations to production schedules are identified and causes for variation are recorded in the agreed format. Range delays, disruptions; causes – material shortages, labour constraints, machinery breakdown, human error, customer requirements or changes to specifications, quantity or delivery. 2.2 Contingency plans for identified causes of variations are developed, agreed, and implemented promptly. 2.3 Master production schedule is revised and includes supplementary material requirements. 2.4 Purchase requisitions for supplementary materials are raised and received by purchasing promptly. 2.5 Revised master production schedule is available to authorised personnel promptly. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the ElectroTechnology Industry Training Organisation reviewcomments@etito.co.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016