Verify machine operation, train users and supervise machine operation in boatbuilding

advertisement

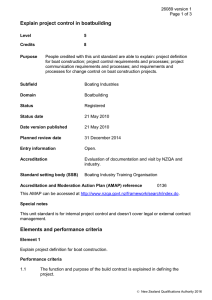

26086 version 1 Page 1 of 3 Verify machine operation, train users and supervise machine operation in boatbuilding Level 5 Credits 10 Purpose People credited with this unit standard are able to verify machine operation in boatbuilding, and train users and supervise the use and care of machines in boatbuilding. Subfield Boating Industries Domain Boatbuilding Status Registered Status date 21 May 2010 Date version published 21 May 2010 Planned review date 31 December 2014 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Boating Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0136 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Machines may include but are not limited to – plate wheeling machine, brake press, drill press, milling machine, vacuum pump, infusion machines, spindle moulder, circular saw, thicknesser, welders (MIG, TIG, ARC), computer numerical controlled machines (CNC), boring machines, band saw, sanding machines, polishing machines. 2 Definitions Company procedures – documented or accepted procedures in the workplace where the unit standard is being assessed. Job requirements – requirements that may or may not be specified but require correct choices to achieve including: following safety and company procedures and meeting generally accepted trade practice standards. New Zealand Qualifications Authority 2016 26086 version 1 Page 2 of 3 3 All work practices must meet recognised codes of practice and documented worksite health and safety procedures (where these exceed code) for personal, product, and worksite health and safety, and must meet the obligations required under the Health and Safety in Employment (HSE) Act 1992, and subsequent and delegated legislation. Elements and performance criteria Element 1 Verify machine operation in boatbuilding. Range minimum of five different machines. Performance criteria 1.1 Status and condition of machines are verified in accordance with company procedures. 1.2 Procedures for maintenance are verified in accordance with company procedures. 1.3 Safe use techniques are verified for each machine in accordance with company procedures. 1.4 Safety equipment requirements are verified for each machine. Element 2 Train users and supervise the use and care of machines in boatbuilding. Range minimum of four users and three different machine types. Performance criteria 2.1 Users are trained in the use and care of the machines in terms of safe use. Range 2.2 Users are trained in the use and care of machines in accordance with job requirements and company procedures. Range 2.3 includes but is not limited to – safe use technique, not using defective tools, cleanliness of tools, ensuring guards are in place, employee responsibilities, personal safety equipment, sharpness of cutting tools, cleanliness of work area, lighting. may include but is not limited to – technique, minimising wastage, accuracy, tolerances, sharpness of cutting tools, replacement of abrasives or cutting blades. Machine use by team members is monitored to ensure it is in accordance with job requirements. New Zealand Qualifications Authority 2016 26086 version 1 Page 3 of 3 2.4 Any non-conformance with machine use requirements is identified and remedied in accordance with machine safe use and job requirements. Range 2.5 Care of machines by team members is monitored to ensure it is compliant with company procedures. Range 2.6 may include but is not limited to – instructing staff to remedy mistakes or inaccuracies. may include but is not limited to – cleaning, resetting. Health and safety aspects of the job are monitored in accordance with company procedures. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Boating Industry Training Organisation info@bia.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016