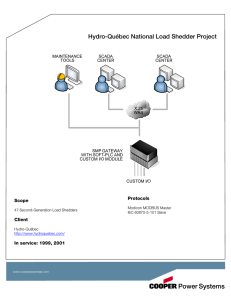

Hydro-Québec Distribution Automation Project

Scope

1 Redundant Front-End Processor (6 planned)

50 SMP 4 Gateways

In service: 2002, 2004

2002-2004, Deploy front-end communications

processor

2002, Deploy SMP 4 gateways

Client

Hydro-Québec

http://www.hydroquebec.com/

www.cooperpowereas.com

Protocols

IEC 60870-5-101

DNP3

SEL

Hydro-Québec proprietary protocols

PG&E 2179 – planned

Devices

SEL 351

S&C M-Series Switch Operators

Serck PDS Compact eNet

Schneider Talus RTU – planned

Cooper F4C – planned

The Solution

The Challenge

Created in 1944 by the Québec government, its only

shareholder, Hydro-Québec supplies electricity to nearly

4 million customers across the province of Québec.

The company also does business with dozens of power

companies in northeastern North America, and

participates in energy-related infrastructure projects on

several continents.

With assets of over $66 billion, annual sales of

$12.7 billion and a work force of 19,297 people,

Hydro-Québec ranks among the leaders of the North

American energy industry.

In 2001, Hydro-Québec launched a project to install an

automation system for its distribution network. HydroQuébec already had six distribution control centers to

cover its network. However, only main distribution

feeders and some 25Kv switches were automated. The

project goal was to integrate more than 4000 overhead

switches in the automation system.

The switch control systems include a variety of IEDs

(Electronic Intelligent Devices), RTUs, and protection

relays, from various providers.

The challenge was to connect a large number of

devices, from various manufacturers, using various

protocols and communications technologies.

Based on its longstanding business relationship, HydroQuébec turned to Cooper Power Systems to find a way

to integrate the field devices in the automation system.

In order to provide a quick start to the project, Cooper

Power Systems began by installing Substation

Modernization Platform™ (SMP) Gateways as front-end

communication processors for selected devices. The

standard SMP Gateway provides all the functionalities

required to integrate IEDs into a control system. It

supports a variety of protocols and can perform control

functions and data acquisition.

To meet the project requirements in a cost effective

manner, Cooper Power Systems then developed a

PC-based front-end communications processor (FEP)

based on (SMP) protocol and communications

technologies.

Cooper Power Systems’ FEP manages

communications with all field devices, performs data

acquisition and provides information to the distribution

control center. It is designed to connect to more than

2000 devices (IEDs) and support 300,000 analog and

binary data points. It is based on Microsoft Windows®

2003 Server and is organized in a cluster configuration

to allow fail-safe transparent redundancy.

The FEP interrogates the field devices using IEC 608705-101 and DNP3 protocols, using any of the following

communications links:

•

•

•

•

TCP/IP Network

Serial links

Telephone or cellular modems

Wireless modems (planned)

Depending on the communication link, the FEP can

provide continuous or on-demand access to the

devices.

Cooper Power Systems used standard SMP 4

Gateways to integrate devices that required protocol

translation or modem communication capabilities.

Quebec City

730 Commerciale Street, Suite 200

Saint-Jean-Chrysostome, Quebec

Canada G6Z 2C5

Technical Support:

P: +1.418.834.0009

support@cybectec.com

Montreal

1290 St. Denis Street, Suite 300

Montreal, Quebec

Canada H2X 3J7

Sales:

P: +1.514.845.6195

sales@cybectec.com

All Cooper logos and Cooper Power Systems are trademarks of Cooper US, Inc., in the U.S. and other countries.

You are not permitted to use Cooper trademarks without the prior written consent of Cooper US, Inc.

©2009 Cooper US, Inc. All Rights Reserved

B1100-09026 • April 2009 • New Issue