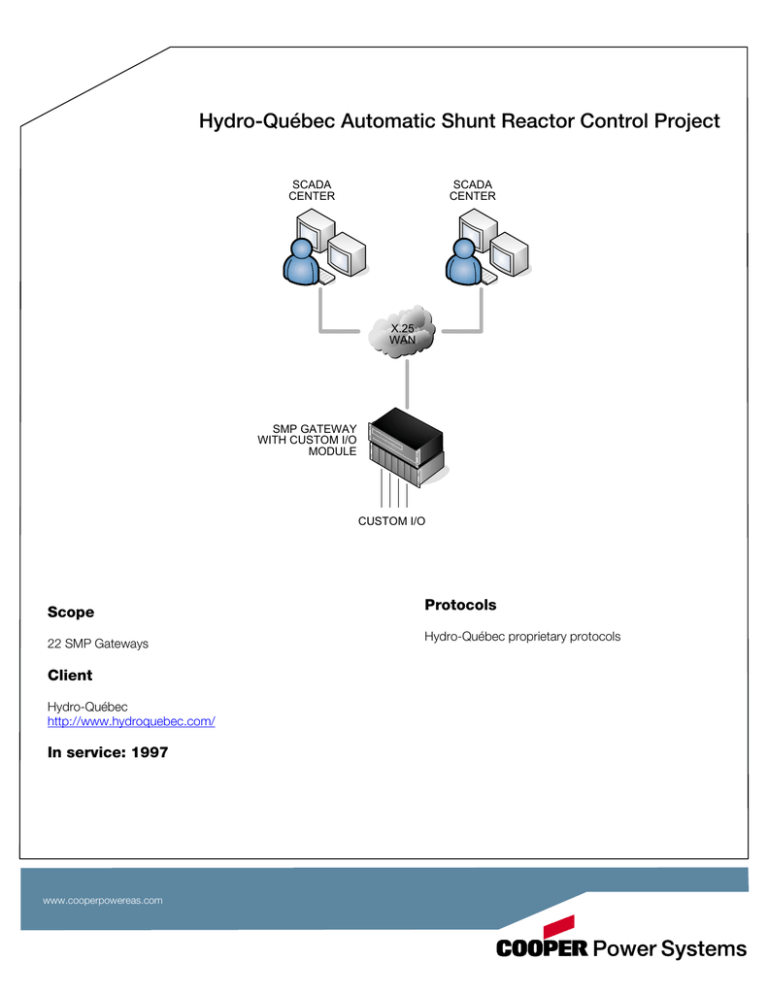

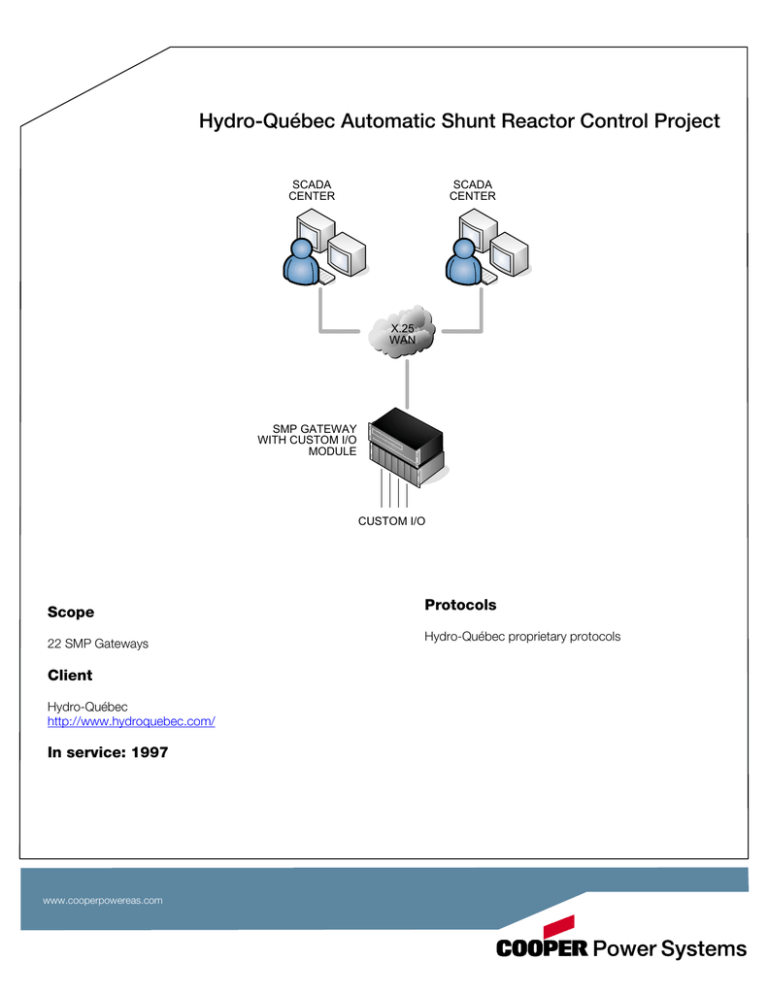

Hydro-Québec Automatic Shunt Reactor Control Project

SCADA

CENTER

SCADA

CENTER

X.25

WAN

SMP GATEWAY

WITH CUSTOM I/O

MODULE

CUSTOM I/O

Scope

22 SMP Gateways

Client

Hydro-Québec

http://www.hydroquebec.com/

In service: 1997

www.cooperpowereas.com

Protocols

Hydro-Québec proprietary protocols

The Solution

The Challenge

Created in 1944 by the Québec government, its only

shareholder, Hydro-Québec supplies electricity to nearly

4 million customers across the province of Québec. The

company also does business with dozens of power

companies in northeastern North America, and

participates in energy-related infrastructure projects on

several continents.

With assets of over $66 billion, annual sales of $12.7

billion and a work force of 19,297 people, HydroQuébec ranks among the leaders of the North

American energy industry.

In 1997, Hydro-Québec wanted to control dynamic

voltage surges on its 735KV transport network, and

turned to Cooper Power Systems for a solution. Cooper

Power Systems had already participated in numerous

major Hydro-Québec projects and proven to be a highly

valuable resource.

Quebec City

730 Commerciale Street, Suite 200

Saint-Jean-Chrysostome, Quebec

Canada G6Z 2C5

Technical Support:

P: +1.418.834.0009

support@cybectec.com

Montreal

1290 St. Denis Street, Suite 300

Montreal, Quebec

Canada H2X 3J7

Sales:

P: +1.514.845.6195

sales@cybectec.com

All Cooper logos and Cooper Power Systems are trademarks of Cooper US, Inc., in the U.S. and other countries.

You are not permitted to use Cooper trademarks without the prior written consent of Cooper US, Inc.

©2009 Cooper US, Inc. All Rights Reserved

B1100-09029 • May 2009 • New Issue

In response to Hydro-Québec's requirement, the

custom software and consulting group designed an

automatic shunt reactor control system and included its

Substation Modernization PlatformTM (SMP) as part of

the solution. The SMP Gateway performs all real-time

data acquisition and implements a sophisticated signalprocessing algorithm to control the shunt reactors in

less than 25 milliseconds.

All communications protocols used for the project are

proprietary and were specifically defined to meet the

stringent requirements imposed by the customer. One

of these protocols is used to acquire real-time data

from the field over a redundant high-speed serial link

(10 Mbps). A second is used to remotely send and

receive parameters, real-time data, application code

and PLC functions from a maintenance console. A third

is used to communicate with a master station for the

purpose of dynamically changing the system's

behavior.