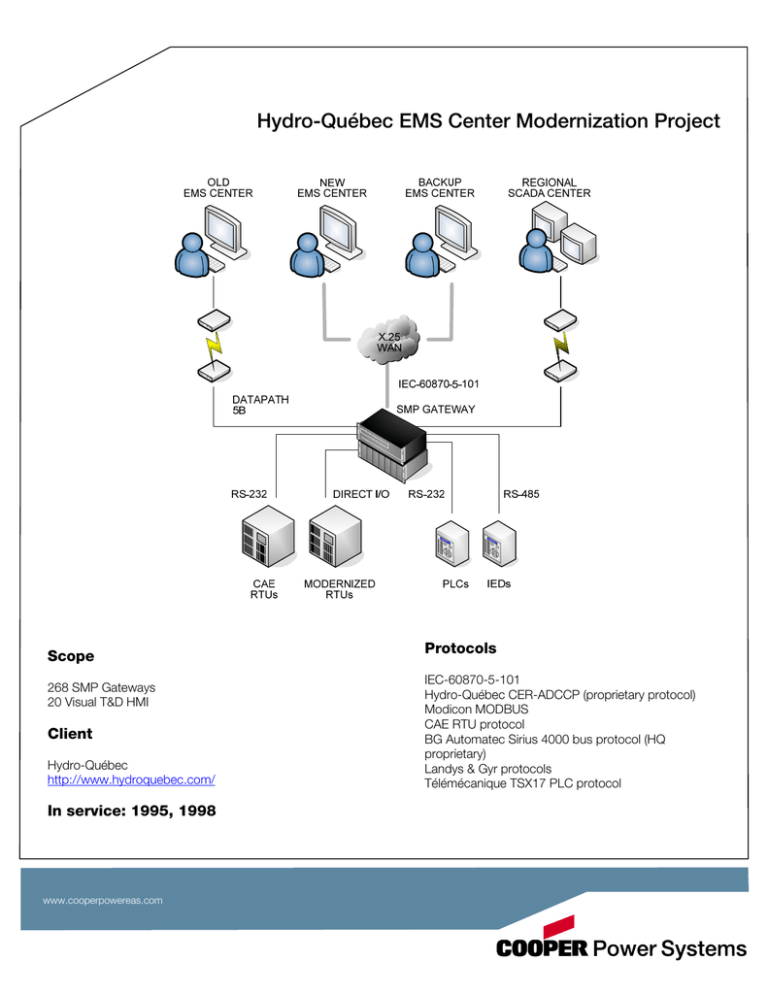

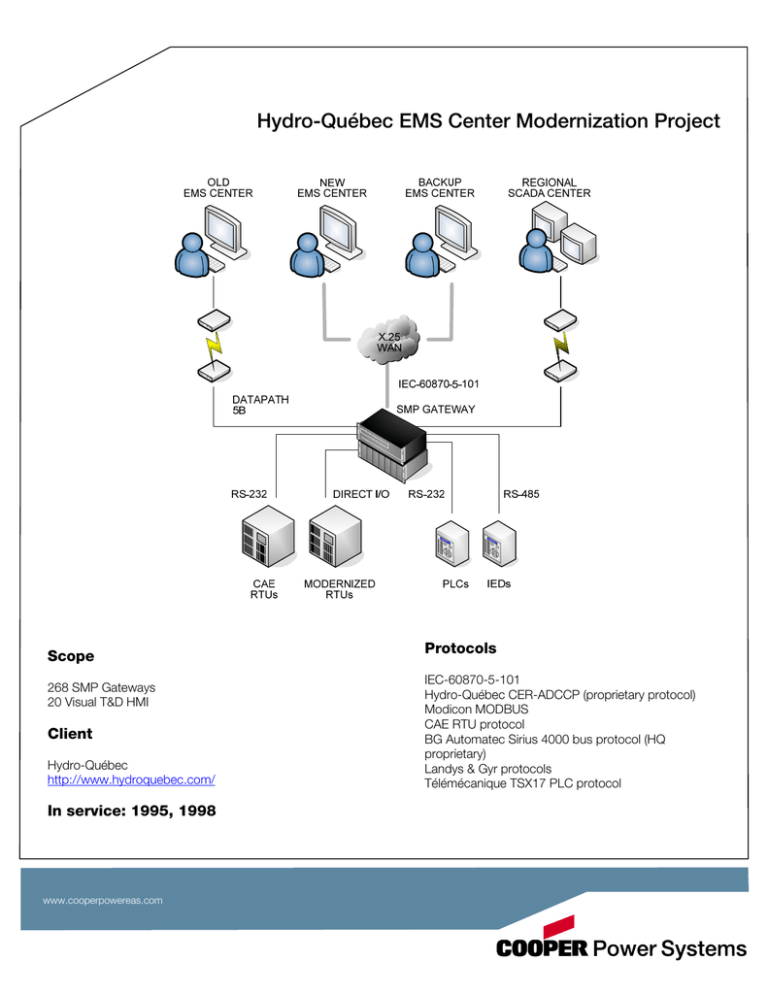

Hydro-Québec EMS Center Modernization Project

Scope

268 SMP Gateways

20 Visual T&D HMI

Client

Hydro-Québec

http://www.hydroquebec.com/

In service: 1995, 1998

www.cooperpowereas.com

Protocols

IEC-60870-5-101

Hydro-Québec CER-ADCCP (proprietary protocol)

Modicon MODBUS

CAE RTU protocol

BG Automatec Sirius 4000 bus protocol (HQ

proprietary)

Landys & Gyr protocols

Télémécanique TSX17 PLC protocol

The Solution

The Challenge

Created in 1944 by the Québec government, its only

shareholder, Hydro-Québec supplies electricity to nearly

4 million customers across the province of Québec. The

company also does business with dozens of power

companies in northeastern North America, and

participates in energy-related infrastructure projects on

several continents.

With assets of over $66 billion, annual sales of

$12.7 billion and a work force of 19,297 people,

Hydro-Québec ranks among the leaders of the North

American energy industry.

In 1995, Hydro-Québec was setting up a new EMS

center and needed to connect over 200 RTUs via its

HYDROPAC network (X.25 WAN). The company turned

to Cooper Power Systems), with which it had a solid

business relationship. Cooper Power Systems had

proven to be a valuable resource for numerous HydroQuébec projects.

Cooper Power Systems designed and implemented the

hardware and software of a communications gateway,

the Cybectec Substation Modernization PlatformTM

(SMP). Initially, the architecture was based on INMOS

Transputer technology. Then in 1998, Cooper Power

Systems produced its second-generation SMP

Gateway. This generation is based on Motorola MPC

860 processors, includes Ethernet, IPack and PCMCIA

interfaces, and supports TCP/IP protocols. A dualprocessor SMP Gateway provides redundant solutions

and greatly enhances availability.

Hydro-Québec currently has over 400 RTUs connected

to its new EMS center and its regional SCADA centers

using Cybectec's SMP Gateway.

The SMP Gateway communicate with the EMS and

SCADA centers using the IEC 60870-5-101 protocol

and Hydro-Québec's CER-ADCCP custom protocol.

They use various protocols to interface with the

substation equipment, including Modicon MODBUS,

CAE`s RTU protocol, BG Automatec Sirius 4000 bus

protocol (proprietary to Hydro-Québec), Landis & Gyr

protocols, and telemecanique TSX17 PLC protocol.

Cooper Power Systems' solution also includes its

Visual T&DTM software, an HMI (Human Machine

Interface) specially designed to meet the requirements

of the electrical power industry. Visual T&D is a powerful

tool that provides a unified view of all the devices in a

power station and of all significant events.

Quebec City

730 Commerciale Street, Suite 200

Saint-Jean-Chrysostome, Quebec

Canada G6Z 2C5

Technical Support:

P: +1.418.834.0009

support@cybectec.com

Montreal

1290 St. Denis Street, Suite 300

Montreal, Quebec

Canada H2X 3J7

Sales:

P: +1.514.845.6195

sales@cybectec.com

All Cooper logos and Cooper Power Systems are trademarks of Cooper US, Inc., in the U.S. and other countries.

You are not permitted to use Cooper trademarks without the prior written consent of Cooper US, Inc.

©2009 Cooper US, Inc. All Rights Reserved

B1100-09027 • May 2009 • New Issue