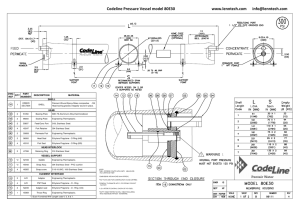

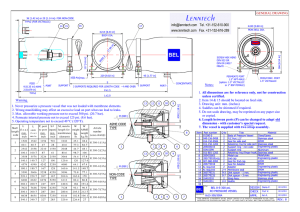

80E60 ... Codeline Pressure Vessel model

advertisement

Codeline Pressure Vessel model 80E60 PART DWG QTY REF NUMBER DESCRIPTION MATERIAL SHELL 01 1 ORDER SECTION SHELL 02 2 51052 Bearing Plate 6061-T6 Aluminium Alloy-Hard Anodized. 03 2 96003 Sealing Plate Engineering Thermoplastic. 04 2 50567 Feed/Conc Port 05 2 45090 Port Retainer Set 06 2 50569 Permeate Port 07 2 45066 Port Nut 08 2 96000 Head Seal Ethylene Propylene - O Ring.(442) 09 4 45312 Port Seal Ethylene Propylene - O Ring.(225) Filament Wound Epoxy/Glass composites - SS Head locking grooves integrally wound in place. HEAD 316L Stainless Steel. CF8M Cast SS, Two-piece set. Engineering Thermoplastic. Engineering Thermoplastic. HEAD INTERLOCK 10 2 47336 Retaining Ring 316 Stainless Steel. VESSEL SUPPORT 11 *2 52169 Saddle 12 *2 45042 Strap Assy. 304 Stainless Steel - PVC cushion Engineering Thermoplastic. 13 4 46265 Strap screw. 5/16-18 UNC, 18-8 Stainless Steel. 14 2 A/R Adapter 15 4 A/R PWT Seal 16 2 52245 Adapter seal 17 1 45069 ELEMENT INTERFACE Thrust Ring Engineering Thermoplastic. Ethylene Propylene - O - Ring Ethylene Propylene - O - Ring (124) Engineering Thermoplastic. * 3 Each Furnished With Length Code 4, 5, 6 & 7. www.lenntech.com info@lenntech.com RATING: PRECAUTIONS: ORDERING: DESIGN PRESSURE……………..600 PSIG at 120° F (4.1 4 M pa @ 49°C) MIN. OPERATING TEMP… …...…… ………….2 0°F (-7° C) FACTORY TEST PRESSURE………..CE / ASME 900 / 780 PSIG (6.2 Mpa) / (5.4 MPa) BURST PRESSURE……..……… …….….3600 PSIG (24 .8 MPa) DO…read, u nderstand and follow all in struction s; failure to take every precaution will void warranty and may resu lt in vessel failure DO…mou nt the shell on horizontal memb ers at sp an “S” using com plaint vessel supports furn ished ; tighten hold down straps just s nug DO…provide o verpressure protection for vessel set at n ot mo re than 10 5% of design pressure DO…inspect end closures regularly; replace compo nents that have d eteriorated and correct causes of corrosion. Usin g the chart below, please check the featu res you require and fax them with your purchase order to ou r customer service department for ex ped ited processing. Fo r optional materials and/or features not listed below, please consult factory for p ricin g and availab ility. INTENDED USE: The CodeLine Model 80 E60 Fiberglass RO Pressure Vessel is d esigned for continuou s, long term use as a housin g for reverse osmosis membran e elements to desalt typical b rackish waters at p ressures up to 600 psi. Any make of eight-inch nominal diameter spiralwou nd element is easily accommodated; the approp riate interfacin g h ardware for the element specified is fu rnished with th e vess el. The CodeLine Mod el 80E60 is des igned in accordance with the engineering standard s of th e Boiler and Pressure Vessel Cod e of th e American Society of Mechanical En gineers (ASME Co de). At small additional cost, v essels can be insp ected du ring construction by an ASME Authorized inspector and ASME Code s tamped. The CodeLine Model 80E60 must be installed operated an d maintained in acco rdance with the lis ted precautions and good in dustrial practice to assure safe operation o ver a lo ng s ervice life. The high performan ce reinforced plastic s hell mus t be allowed to expand und er pressure; un due restraint at supp ort points or piping connections can cause leaks to develo p in the shell. The end closure, incorporating clos e fitting, interlo cking metal compon ents, must be kept dry and free of corro sion; d eterioration can lead to catastro phic mechanical failure of the h ead . The end closu res, incorp orating close-fittin g, interlock in g metal components, must be kept dry and free of corro sion; d eterioration can lead to catastrop hic mechanical failure of the heads. Pen tair Water will assist the p urchaser in d etermining the suitab ility o f this standard vessel for their specific operatin g cond itions . The final determin ation however, inclu ding evaluation of the standard material of con struction fo r compatibility with the specific corro sive environ ment, shall be the responsibility of the pu rch aser. Specifications are subject to change with out n otice. 99109-J © Pentair Water Page 2 of 2. Please note that we req uire you r membrane brand an d model number wh en ordering. If this information is not initially av ailable, you may provid e it at a later date by checking the appropriate box below. VESSEL LENGTH CODE – please check one MODEL 80 E60 -1 -2 -3 -4 -5 -6 -7 DO NOT… make rig id pip in g connections to ports o r clamp vessel in an y way that resists growth o f fib erglass sh ell under pressure; ∆DIA = 0 .01 5 in. (0.4mm) and ∆L = 0.2 in. (5 mm) for a length code –7v essel DO NOT… h an g p ip ing manifold s from po rts or u se v essel in an y way to sup port other compo nents; b ranch con nection piping may be simp ly supported b etween the h eader and po rt; maximum weigh t o f bran ch pipin g; feed/concentrate – 16 lbs (7.3 kg); permeate – 8 lbs (3 .6 kg) DO NOT… op erate vessel at pressures and temperatures in ex cess o f its rating DO NOT… o perate vessel with out permeate ports intern ally conn ected with a complete set of elements and interconnecting hardware DO NOT… op erate vessel with permeate pressure in excess o f 125 p si at 120°F (0 .86 M Pa @ 4 9°C) DO NOT… overtigh ten the con nection to the p ermeate port (hand-tigh ten p lu s one-q uarter tu rn, check for leak s) DO NOT… tolerate leaks o r allow en d closu res to b e rou tinely wetted in any way DO NOT… pressu rize vessel until doub lecheck in g to verify th at the retaining ring is completely inside the groove DO NOT… work on any comp onent un til firs t v erifying that pressure is relieved from vessel DO NOT… operate at pH levels below 3 or ab ove 10 MEMBRANE BRAND AND MODEL – plea se check one a nd fill in info rmatio n Please sup ply adapters for the following membran e brand and specific model Brand_ ______ ______ _______ _____Mod el___ ______ _______ ______ _ CERTI FICATION REQUI RED ASM E Stamped and Nation al Board Registered (please consult factory for pricing) CE Marked Standard, Certified b y Pen tair water. EXTERI OR FINISH – plea se check one Standard – white high-g los s po lyu rethan e coating. Option – op tion al colors are available for 50 or more vessels p er order. Call factory for p ricin g details. MATERIAL OPTIONS Standard – All materials as per d rawing 99109 on the first page. Customer specified materials: (Pleas e cons ult the factory, as these options will affect pricing and vessel lead-tim e.) >ĞŶŶƚĞĐŚďǀ ZŽƚƚĞƌĚĂŵƐĞǁĞŐϰϬϮŵ ϮϲϮϵ,,ĞůĨƚ dĞů͘нϯϭͲϭϱͲϮϲϭ͘Ϭϵ͘ϬϬ &Ădž͘нϯϭͲϭϱͲϮϲϭ͘ϲϮ͘ϴϵ www.lenntech.com info@lenntech.com