ARMt'ES JUN by LIBRARIES

advertisement

Microbial Engineering for Aldehyde Synthesis

by

by

ARMt'ES

MASSACHUSETT INSTIrJTE

OF rECH.ULOLGY

Aditya Mohan Kunjapur

JU

JUN 2 2 2015

Bachelor of Science in Chemical Engineering

University of Texas at Austin, Austin, TX, USA, May 2010

LIBRARIES

Submitted to the Department of Chemical Engineering

In Partial Fulfillment of the Requirements for the Degree of

Doctor of Philosophy in Chemical Engineering

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June 2015

2015 Massachusetts Institute of Technology. All rights reserved.

Signature redacted

Signature of Author..................

.........

.................

.

........

Aditya M. Kunjapur

Department of Chemical Engineering

Mav 19. 2015

Signature redacted

C e rtified by ..........................................................................

..

...........

.................................................

Kristala L. Jones Prather

Associate Professor of Chemical Engineering

Thesis Supervisor

.Signature redacted

A cce pted by............................................................................

.. ....................

.............................

........

Richard D. Braatz

Professor of Chemical Engineering

Chairman, Committee for Graduate Students

Microbial Engineering for Aldehyde Synthesis

by

Aditya Mohan Kunjapur

Submitted to the Department of Chemical Engineering on May 19, 2015

in Partial Fulfillment of the Requirements for the Degree of

Doctor of Philosophy in Chemical Engineering

Abstract

Microbes have been engineered to produce many useful classes of chemicals from

renewable carbon sources instead of from finite petroleum reserves. Aldehydes represent a class

of chemicals that has been challenging to obtain using microbes given the rapid conversion of

aldehydes into their corresponding alcohols that occurs naturally. Microbes are thought to have

evolved numerous endogenous enzymes responsible for catalyzing these conversions in order to

alleviate the negative effect of many aldehydes on cellular processes.

In this thesis, we investigate several aspects of microbial aldehyde synthesis. Driven first

by the hypothesis that targeted gene deletions could decrease endogenous aldehyde reduction

in a model E. coli host strain, we demonstrate that benzaldehyde accumulation occurs upon

deletion of a combination of genes encoding enzymes known to have benzaldehyde reductase

activity in vitro. Using deletion subset studies and quantitative real-time PCR, we discover that

deletion of many, but not all, of these genes is required to curtail endogenous reduction. We also

show that the same engineered strain has a significantly decreased rate of reduction of other

aromatic aldehydes. As an added benefit, cell growth rate is unaffected by these deletions. We

demonstrate the utility of this strain for two applications: (i) conversion of glucose into vanillin,

which is the most widely used flavoring additive; and, (ii) conversion of benzaldehyde and glucose

into L-phenylacetylcarbinol, which is a chiral pharmaceutical intermediate.

We next explore the ability to produce and retain non-aromatic aldehydes with the

specific objective of studying the conversion of fatty aldehydes into gasoline-range alkanes. We

find that a carboxylic acid reductase (Car) from Nocardia iowensis achieves biosynthesis of

aldehydes from free fatty acid substrates ranging in carbon chain length from C4 to C10. The use

of Car, the engineered host strain, and previously elucidated pathways to free fatty acids enables

production of alkanes ranging from C3 to C9. Although alcohol byproduct formation significantly

decreases, it does not significantly increase alkane titer because of poor aldehyde decarbonylase

kinetics.

Additional work presented in this thesis seeks to identify and surmount limitations in

aldehyde biosynthesis in vitro and in E. coli de novo vanillin biosynthesis.

Thesis Supervisor: Kristala L. Jones Prather

Title: Associate Professor of Chemical Engineering

3

Dedication

My mother, Shaku Kunjapur, once ran a pediatric clinic in Hyderabad, India, after

completing her medical studies there. Soon after marrying my father, she closed down her

practice and followed him to America, where he had begun pursuing a Master's Degree in

Engineering. Although my father's interest and perseverance in earning an American education

were vital to later providing me with opportunities that few of my kin in India could dream of,

this short story remains about my mother's sacrifice. Once she passed the medical residency

exams required of foreign educated doctors in order to ultimately practice in the U.S., she had a

newfound constraint in the form of me. This became especially challenging when my father's

engineering career took us to Houston, Texas, and my mother reluctantly began her residency

four hours away in the city of Corpus Christi. I was a toddler at the time and one of the earliest

memories that I still retain was a weekend trip to Corpus Christi to visit her. In a few months, my

mother quit her residency and became a stay-at-home mom. Even as I grew older and remained

an only child, she maintained an immensely loving and nurturing environment at home. The

privilege of receiving so much attention from her imparted a sense of responsibility in me to

make a difference in society on behalf of her and me. These were the foundations that fostered

the lofty aspirations that drive me today. And that is why this doctoral thesis is dedicated to my

mom, the real Dr. Kunjapur.

4

Acknowledgements

Countless individuals have supported me throughout my journey at MIT. Foremost on this

list is my advisor, Professor Kris Prather, who took me into her lab and patiently guided me along

as I began with minimal working knowledge of biology. She displayed tremendous understanding

over the years as my growing appreciation for experimentation strayed beyond my initial

objectives and even occasionally beyond the laboratory bench. I also benefited immensely from

her participation with other members of the synthetic biology community and from her

recruitment of many talented and kindhearted individuals who I can call labmates.

I had the opportunity to engage with other world-class faculty members during my time

at MIT and am especially grateful for the perspectives shared by Professors Charlie Cooney, Amy

Keating, and John Dueber. Besides serving on my thesis committee, these professors cared to

meet with me individually and to provide valuable constructive criticism. I am a better scientist

because of their interest in my project and in my development.

I mentioned labmates earlier, but several individuals from the Prather Lab deserve

personal recognition. Dr. Micah Sheppard taught me most of what I know about so many aspects

of research, including metabolic pathway design, controlled experimentation, and even effective

scientific illustration. In addition to nurturing my intellectual growth, Micah's selfless interest in

regularly discussing diverse aspects and implications of my project ultimately led to exciting

collaborations on biofuel production. With regard to collaborations, I am also grateful to Kat

Tarasova for her interest in the aromatic aldehyde work and for developing a method for their

detection, replicating my initial encouraging results, and helping develop and edit the potential

story as it unfolded. I also had many fruitful scientific discussions with Dr. Kevin Solomon and Dr.

Himanshu Dhamankar that increased my understanding of the field, and I acquired important lab

skills with the help of Dr. Matt McMahon, Dr. Chris Reisch, Dr. Eric Shiue, Dr. Hsien-Chung Tseng,

and Dr. Diana Ritz. I was privileged to experience my MIT journey alongside my classmate and

labmate Irene Brockman and especially enjoyed the summers that we synthesized and shared

our budding knowledge of metabolic engineering principles to high school students together.

Finally, I would like to thank the undergraduate research assistants who I worked with for their

help in achieving diverse research objectives and for the many things I learned from them:

Bernardo Cervantes, Spencer Wenck, Nikita Khlystov, Asmamaw Wassie, and Jason Hyun.

Several organizations made invaluable contributions to my professional development at

MIT. I extend my deepest gratitude to everyone I worked with in the MIT Energy Club and in the

Synthetic Biology Engineering Research Center (SynBERC) for providing me with great

opportunities, for inspiring me, and for trusting me to help manage initiatives that hopefully

aided the professional development of other students. I would also like to thank my SynBERC

Industrial Mentor, Todd Peterson, for volunteering his time towards being a terrific mentor and

providing perspectives on research that are rarely found in academic contexts.

This research would not have been possible without significant financial support, and for

that I would like to thank the National Science Foundation, SynBERC, and Dr. Pete Bixler. I also

thank the following agencies for providing more focused funding: MITei, Dow, and the GSC.

There are so many mentors and friends left to thank, but so little space. However, I would

be remiss without expressing my appreciation for Dr. Bruce Eldridge and for Nancy McBride, who

have each provided exceptional support for my academic pursuits since my days in Texas.

5

Table of Contents

Abstract...........................................................................................................................................

3

Dedication .......................................................................................................................................

4

Acknow ledgem ents.........................................................................................................................5

Table of Contents............................................................................................................................

6

List of Figures..................................................................................................................................

9

List of Tables .................................................................................................................................

13

Chapter 1: Introduction ................................................................................................................

14

1.1. Biological aldehydes........................................................................................................

14

1.2. Engineering aldehyde biosynthetic reactions and pathways ........................................

15

1.3. Minimizing endogenous conversion of aldehydes to alcohols ......................................

25

1.4. Enhancing bioconversion of aldehydes to other chemical classes ................................

26

1.5. Addressing aldehyde toxicity .........................................................................................

27

1.6. Thesis organization.........................................................................................................

30

Chapter 2: Engineering synthesis and accumulation of aromatic aldehydes in E. coli............. 32

2.1. Introduction........................................................................................................................

32

2.2. M aterials and M ethods.................................................................................................

34

2.2.1. Strains and plasm ids.................................................................................................

34

2.2.2. Chem icals.....................................................................................................................

39

2.2.3. Culture conditions ...................................................................................................

39

2.2.4. M etabolite analysis..................................................................................................

41

2.2.5. Quantitative Reverse Transcription PCR (qRT-PCR) ................................................

42

2.3. Results................................................................................................................................43

2.3.1. A combination of rationally targeted gene deletions enables benzaldehyde

accum ulation in E. coli.................................................................................................

.. 43

2.3.2. In vanillate-feeding experiments, the RARE strain eliminates conversion of vanillin into

vanillyl alcohol.......................................................................................................................

49

2.3.3. The RARE strain enables production of vanillin from glucose in E. coli.................. 51

6

2.3.4. The RARE strain enables the synthesis of L-PAC in E. coi....................................... 54

2.3.5. The deletion of all targeted genes to form the RARE strain has no effect on growth 57

2.4. Discussion ...........................................................................................................................

59

Chapter 3: Decreasing endogenous reduction of aliphatic aldehydes and the effect on

biosynthesis of gasoline-range n-alkanes ................................................................................

64

3.1. Introduction........................................................................................................................

64

3.2. M aterials and M ethods.................................................................................................

69

3.2.1. Strains and M odules .................................................................................................

69

3.2.2. Chem icals.....................................................................................................................

72

3.2.3. Culture Conditions....................................................................................................

73

3.2.4. M etabolite Analysis .................................................................................................

73

3.3. Results ................................................................................................................................

74

3.3.1. Modules 1-Ma, 3-Oc, and 4-LA Result in Heptane and Nonane Biosynthesis ........ 74

3.3.2. Substitution of an RBO Module (Module 2-MCC) Results in Biosynthesis of Pentane as

the Sole Alkane Product ...................................................................................................

78

3.3.3. M odules 1-Pr, 2-M CC, and 4-SA Enable Butane Biosynthesis................................. 79

3.3.4. M odules 2-BC and 4-SA Enable Propane Biosynthesis............................................ 80

3.4. Discussion ...........................................................................................................................

81

Chapter 4: Enhancing in vitro aldehyde biosynthesis by pairing carboxylic acid reductase with

inorganic pyrophosphatase ......................................................................................................

84

4.1. Introduction........................................................................................................................

84

4.2. M aterials and M ethods .................................................................................................

86

4.2.1. Plasm id construction ..............................................................................................

86

4.2.2. Chem icals.....................................................................................................................

88

4.2.3. Enzym e purification .................................................................................................

88

4.2.4. Kinetic studies.........................................................................................................

90

4.3. Results ................................................................................................................................

92

4.4. Discussion ...........................................................................................................................

98

Chapter 5: Towards improving de novo vanillin biosynthesis in E. coli by deregulating Sadenosylmethionine biosynthesis ..............................................................................................

101

7

5.1. Introduction......................................................................................................................

101

5.2. M aterials and M ethods ....................................................................................................

105

5.2.1. Strains and plasm ids..................................................................................................

105

5.2.2. Chem icals...................................................................................................................

110

5.2.3. Culture conditions .....................................................................................................

110

5.2.4. M etabolite analysis....................................................................................................112

5.2.5. SDS-PAGE analysis .........................................................................................................

113

5.3. Results ..............................................................................................................................

114

5.3.1. Focusing on central carbon m etabolism first ............................................................

114

5.3.2. Understanding why conversion of protocatechuate to vanillate was limiting: SAM 118

5.3.3. Investigating potential bottlenecks in SAM biosynthesis.......................................... 120

5.3.4. Improving vanillate production by deregulating SAM biosynthesis ......................... 123

5.4. Discussion .........................................................................................................................

Chapter 6: Lessons Learned and Future Directions....................................................................

129

132

6.1. Sum m ary ..........................................................................................................................

132

6.2. Future Directions..............................................................................................................

135

6.2.1. M etabolite sensors for the vanillin pathw ay.............................................................

136

6.2.2. Use of CoA-dependent pathways to generate novel aliphatic aldehydes................137

6.2.3. M icrobial aldehyde toxicity .......................................................................................

References ..................................................................................................................................

138

140

8

List of Figures

Figure 1 - 1. Overview of natural metabolic pathways that can be harnessed for the conversion

of glucose to valuable aromatic and aliphatic aldehydes through carboxylic acid intermediates

based on E. coli metabolism. Aldehydes can also be obtained from the 2-keto acid pathway,

terpenoid pathways, and other pathways................................................................................

19

Figure 1- 2. Potential biocatalytic and metabolic engineering opportunities that could be enabled

by, or enhanced by, microbial aldehyde accumulation.......................................................... 26

Figure 2 - 1. A combination of rational gene deletions enables benzaldehyde accumulation in E.

coli. (A) Scheme depicting intracellular formation of benzaldehyde from benzoate and

endogenous conversion to the byproduct benzyl alcohol. (B) Conversion of 5 mM benzoate after

24 hours in strains transformed with pETDuet-1 and pACYC-car-sfp. (C) Conversion of 5 mM

benzoate after 24 hours in RARE strains transformed with pACYC-car-sfp and a pET plasmid

harboring the gene indicated below the x axis.........................................................................

47

Figure 2 - 2. Estimated copies of reverse transcribed mRNA per nanogram of total RNA based on

quantitative reverse transcription PCR (qRT-PCR). ..................................................................

48

Figure 2 - 3. In vanillate-feeding experiments, the RARE strain eliminates conversion of vanillin to

vanillyl alcohol. (A) Scheme depicting intracellular formation of vanillin from vanillate and

endogenous conversion to the byproduct vanillyl alcohol. (B) Conversion of 5 mM vanillate after

48 hours in strains transformed with pETDuet-1 and pACYC-car-sfp. (C) Conversion of 5 mM

vanillate after 24 hours in RARE strains transformed with pACYC-car-sfp and a pET plasmid

harboring the gene indicated below the x axis......................................................................... 50

+

Figure 2 - 4. The RARE strain enables production of vanillin from glucose in E. coli. (A) Scheme

depicting complete pathway from glucose to vanillin with overexpressed E. coil aroG* indicated

in bold typeface. [PYR = pyruvate, F6P = fructose 6-phosphate, G3P = glyceraldehyde 3phosphate, X5P = xylulose 5-phosphate, PEP = phosphoenolpyruvate, E4P = erythrose 4phosphate, DAHP = 3-deoxy-D-arabinoheptulosonate 7-phosphate, DHQ = 3-dehydroquinate,

DHS = 3-dehydroshikimate] (B) Scheme illustrating heterologous portion of pathway with two

possible undesired alcohol byproducts. (C) Concentration profiles of the six heterologous

metabolites of interest (including vanillin) when wild-type and RARE hosts are transformed with

pET-OMT-asbF and pACYC-car-sfp-aroG* plasmids and grown in LB + 1.2% glucose for 48 hours.

(D) Concentration profiles of the six heterologous metabolites of interest (including vanillin)

produced from glucose as a sole carbon source after 60 hours in the same strains grown in M9

1.2% gluco se . ................................................................................................................................

52

Figure 2 - 5. Concentration of isovanillin at final time points from experiments (either 48 hours

for LB or 60 hours for M9) that examined the production of vanillin from glucose............... 54

Figure 2 - 6. The RARE strain enables the synthesis of L-phenylacetylcarbinol (L-PAC). (A) Scheme

depicting the synthesis of L-PAC from the condensation of exogenously supplied benzaldehyde

and metabolized pyruvate, catalyzed by either PDC or PDC_E473Q. (B) Concentration profiles of

9

PAC, benzaldehyde, and benzaldehyde oxidation/reduction products 24 hours after addition of 5

mM benzaldehyde to RARE and wild-type host strains. (C) Time course of benzaldehyde reduction

using the wild-type host transformed with pRSF/PDCE473Q and pACYC/Car/Sfp................ 56

+

Figure 2 - 7. OD600 measurements of MG1655 and RARE strains when grown in (A) LB medium

1.2% glucose or (B) M9 minimal media + 1.2% glucose. (C) Specific growth rates of each strain

calculated from experiments in the different media listed above........................................... 58

Figure 2 - 8. OD 6oo measurements at final time points from reported experiments: (A)

benzaldehyde from benzoate; (B) vanillin from vanillate; (C) vanillin from LB + 1.2% glucose; (D)

vanillin from M 9 + 1.2% glucose.............................................................................................. 59

Figure 3 - 1. Relative activity of the carboxylic acid reductase from Nocardia iowensis (CarNi) on

straight and branched aliphatic acids ranging in carbon chain length from C2 to C8. ............ 65

Figure 3 - 2. Biochemical pathway illustration depicting fatty aldehydes as a precursor to either

an alkane or an alcohol.............................................................................................................

66

Figure 3 - 3. (A) Composition of typical regular unleaded gasoline displayed in weight percent (wt.

%) based on the average of Refs. 146 and 147. Single asterisk indicates that compounds below

0.5 wt. %are not reported in Ref. 147. Double asterisks indicate that wt. % includes contribution

from trace compounds in Ref. 146. (B) Modular pathway design used for selective synthesis of

key gasoline-range alkanes in engineered E. coli. Genes in gray within Modules 1-Pr and 1-Ma are

native and were not overexpressed, whereas genes in black were overexpressed. Module names

are abbreviations for the following: "Pr" = Propionate; "Ma" = Malonyl-ACP; "BC" = Butyrl-CoA;

"MCC" = Medium-Chain-CoA; "Oc" = Octanoate; "SA" = Short Alkanes; "LA" = Long Alkanes. .. 68

Figure 3 - 4. Selective production of heptane and nonane using FAS for carbon chain extension.

(A) C8 and C10 FFA titers resulting from Module 3-Oc or Modules 1-Ma and 3-Oc in WTAfadD. (B)

Gas-phase titers of octanal observed 24 hours after supplying octanoate to WT and RARE

expressing CarNi. (C) Illustration of octanal as a branch-point metabolite to heptane or octanol.

(D) Alkane titers resulting from Modules 1-Ma, 3-Oc, and 4-LA in WTsAfadD and RAREnfadD.

Experiments performed in triplicate with averages as reported values and standard deviation as

error bars. All alkane titers are gas-phase................................................................................

76

Figure 3 - 5. Selective production of pentane using RBO for carbon chain extension. (A) Liquidphase titers of hexanoate and downstream metabolites observed 24 hours after supplying

hexanoate to WT and RARE expressing CarNm. (B) Alkane titers resulting from Modules 2-MCC and

either 4-LA or 4-SA in WT and RARE. (C) Liquid-phase titers of butanol and hexanol in WT and

RARE containing Modules 2-MCC and 4-SA. Experiments performed in triplicate with averages as

reported values and standard deviation as error bars. All alkane titers are gas-phase. ......... 77

Figure 3 - 6. Alternative modules enable synthesis of butane and propane. ..........................

80

Figure 3 - 7. Intermediate and byproduct profiles associated with propane synthesis. (A) Relative

butyraldehyde concentrations in the headspace of cultures containing Modules 2-BC and 4-SA.

An increased concentration of butyraldehyde was observed in the gas phase using RARE. (B)

Liquid-phase concentrations of butyraldehyde and butanol in cultures containing Modules 2-BC

10

and 4-SA. Increased levels of butyraldehyde and decreased levels of butanol were observed in

the liquid phase using RARE ......................................................................................................

81

Figure 4 - 1. Effect of varying MgC 2 concentration or adding commercial inorganic

pyrophosphatase (Ppa) from New England Biolabs on Car-catalyzed conversion of the substrate

benzoate. The concentration of Car used was 224 nM. The units of Ppa added was 0.1, where

one unit is as defined by NEB (The amount of enzyme that will generate 1 pmol of phosphate per

minute from inorganic pyrophosphate under standard reaction conditions [a 10 minute reaction

at 250 C in 20 mM Tris-HCI, pH 8.0, 2 mM MgC1 2 and 2 mM PPi]). Experiment performed in

duplicate. Data points shown are averages with error bars representing standard deviations.. 94

Figure 4 - 2. Effect of MgC 2 concentration and addition of an "in-house" Ppa (896 nM) on an in

vitro reaction pathway involving Car (224 nM) and a heterologous aldo-keto reductase, YtbE

(1422 nM). To ensure that no other component of the commercial Ppa mixture was responsible

for the reaction enhancement, we expressed and purified the E. coli ppa gene product. We

included an aldo-keto reductase that catalyzes the conversion of benzaldehyde into benzyl

alcohol to investigate whether the reaction catalyzed by Car would be enhanced simply by

creating a sink for the product. Subsequent experiments showed that the higher concentration

of MgC2 slightly reduced the activity of the second enzyme. Experiment performed in duplicate.

.......................................................................................................................................................

95

Figure 4 - 3. Addition of Ppa enables an in vitro pathway involving Car and an aldo-keto reductase

to be modeled with far greater accuracy using Michaelis-Menten kinetics and parameters

obtained from initial rate measurements. Model parameters: KM,Car-GBD = 0.35 mM; KM,YtbE-SH3 = 2

mM; kcat, Car-GBD 216 min-; kcat,YtbE-SH3 = 96 min 1 . Data points represent the average of duplicate

experim ental values......................................................................................................................

96

Figure 4 - 4. Effect of Ppa addition on the Car-catalyzed conversions of two substrates that result

in aldehydes valuable as flavors. X represents the conversion of substrate C (X = C,/Cio).

Experim ent perform ed in duplicate. ........................................................................................

97

Figure 4 - 5. Effect of the molar ratio of Ppa to Car on conversion of benzoate. The concentration

of Car was fixed at 224 nM. The purpose of this experiment was to help determine the minimum

amount of Ppa required to add relative to Car in order to achieve saturating levels of

enhancement. All ratios tested achieved saturating enhancement. Experiment performed in

d u p licate. ......................................................................................................................................

98

Figure 5 - 1. The engineered vanillin pathway in E. coli. (A) Endogenous portion of the vanillin

pathway. (B) Heterologous portion of the vanillin pathway, with reactions catalyzed by CarNi

shaded in gray. Genes corresponding to enzymes labeled in red are overexpressed in experiments

investigating improvement of vanillate production. Enzymes written without subscripts are

native to E. coli. The heterologous pathway portion in the engineered yeast vanillin pathway

contains identical metabolites and enzymes with the exception of AsbFBt............................... 103

11

Figure 5 - 2. Effect of perturbations in central metabolism intended to increase PEP and E4P

availability on heterologous metabolite titers and specific yields. (A) Deletion of PTS- glu' did not

improve titers of either protocatechuate or vanillate. (B) Overexpression of ppsA and tktA in the

PTS~ glut RARE' host resulted in an increase in protocatechuate titer and specific yield compared

to expression of the pathway without ppsA and tktA. (C) Bioreactor culture of PTS- glu* RARE'

host expressing the pathway (without ppsA and tktA overexpression) leads to increased

protocatechuate titers without a concomitant increase in vanillate titers, indicative of room for

improvement in the conversion of protocatechuate to vanillate. Host in blue text, overexpressed

genes in red text. ........................................................................................................................

118

Figure 5 - 3. Identification of the bottleneck in vanillate production. (A) SDS-PAGE result showing

robust expression of OMTHs. (B) Effect of 10 mM L-methionine supplementation at peak

productivity (24 h) on vanillate titers, with and without overexpression of metK. (C) Pathway

illustrating the reaction catalyzing conversion of protocatechuate into vanillate in the context of

SAM biosynthesis and recycling. (D) Effect of 2.5 mM L-homocysteine supplementation at peak

productivity (24 h) on vanillate titers and specific yield. In both pathway experiments shown here

(B and D), the PTS~ glut RARE' host overexpressing aroG*, ppsA, tktA, asbF, and OMTwas tested.

.....................................................................................................................................................

1 19

Figure 5 - 4. Effect of meti deletion (A) in different host strains and (B) in the presence of amino

acid supplementation. For these experiments, the following genes were overexpressed: aroG*,

ppsA, tktA, asbF, and OMT. For the amino acid supplementation experiment (B), 10 mM of amino

acid w as added at induction.......................................................................................................

124

Figure 5 - 5. Effect of metA* and cysE* overexpression. (A) Effect of overexpressing feedbackdesensitized variants of metA and/or cysE along with usual pathway constructs in the RARE Ametj

host. The control represents co-transformation with an empty pCOLADuet-1 plasmid. (B) Effect

of methionine supplementation level and timing on vanillate titers in metA*-cysE* cultures. (C)

Kinetics of vanillin production without overexpression of metA*-cysE*. (D) Kinetics of vanillin

production with overexpression of metA*-cysE*. Although final titers achieved in (C) and (D) are

similar, the metA*-cysE* cultures grow more slowly, produce vanillin more slowly, but display

greater conversion of protocatechuate to vanillate................................................................... 126

Figure 5 - 6. Images of plates testing for potential loss of ampicillin-resistant plasmid. No

significant plasmid loss was observed for samples taken at 24, 48, and 72 h. .......................... 128

Figure 5 - 7. The activated methyl cycle in E. coli (in black), along with an alternative SAH recycling

route featuring a heterologous SAH hydrolase (sahH, in blue).................................................. 131

12

List of Tables

Table 1 - 1. Relevant published aldehyde biosynthesis patent applications. ..........................

22

Table 2 - 1. Strains and plasmids used in this study.................................................................

35

Table 2 - 2. Oligonucleotides used in this study......................................................................

37

Table 2 - 3. Reported activities of E. co/i gene products on benzaldehyde in vitro. ................ 45

Table 2 - 4. Results of protein BLAST sequence alignments used to organize deletion targets. 45

Table 2 - 5. E. coli strains featuring different combinations of gene deletions ("X" indicates

d e letio n )........................................................................................................................................

46

Table 3 - 1. Performance and separation metrics for select gasoline alternatives and constituents.

.......................................................................................................................................................

67

Table 3 - 2. Strains and modules used in this study. ................................................................

71

Table 3 - 3. Oligonucleotides used in this study......................................................................

72

Table 4 - 1. Oligonucleotides used in this study......................................................................

88

Table 4 - 2. Combinatorial testing of in vitro components for formation of precipitate.......... 93

Table 5 - 1. Strains and plasm ids used in this study ...................................................................

107

Table 5 - 2. Synthesized gene sequences used in this study...................................................... 109

Table 5 - 3. Oligonucleotides used in this study.........................................................................

110

13

Chapter 1: Introduction

Portions of this chapter are adapted from thefollowing manuscript: Kunjapur A.M. and Prather

K.L.J. (2015), AppL. Environ. Microbiol., 81 (6)1892-1901.

1.1. Biological aldehydes

The word "aldehyde" was coined in the early

1 9 th

century by Justin von Liebig, who

formed a contraction using the Latin words "alcohol dehydrogenatus," or "alcohol deprived of

hydrogen" (1). Aldehydes have a variety of industrial uses, but they are perhaps most familiar for

their effects on two of the mammalian senses: olfaction and gustation. Numerous aldehyde

odorants are known to bind to G-protein-coupled receptors, triggering reaction cascades that

ultimately result in mammalian perception (2-5). At dilute concentrations, fatty aldehydes such

as hexanal, octanal, decanal, and dodecanal offer apple, citrus, orange peel, and violet scents,

respectively (6). Aromatic aldehydes, such as benzaldehyde, anisaldehyde, vanillin, and

cinnamaldehyde, are responsible for the natural fragrances of almond, sweet blossom, vanilla,

and cinnamon, respectively (6, 7). Notable terpenoid aldehydes include citral, which provides

lemon scent (6), and safranal, which is one of the primary molecules responsible for saffron

aroma (8). Aldehydes play a role in other animal phyla as well. Certain aldehydes, such as trans2-hexenal, phenylacetaldehyde, and nonanal, evoke responses in insects by serving as

pheromones or attractants (9-11). The high reactivity of the carbonyl group of aldehydes enables

many industrial uses beyond flavors and fragrances, such as precursors to pharmaceuticals (1215). However, the high reactivity of aldehydes also contributes to their increased toxicity in

microorganisms. Given the high-value applications and large markets for several aldehydes,

14

commercial focus on microbial aldehyde synthesis has surged in recent years (16). This chapter

summarizes published efforts towards microbial engineering for aldehyde synthesis, with an

emphasis on de novo aldehyde synthesis, attempts at engineering aldehyde accumulation in E.

coli, and the challenge of aldehyde toxicity.

1.2. Engineering aldehyde biosynthetic reactions and pathways

Because most microbes do not naturally accumulate aldehydes, microbial production of

these molecules from simple carbon sources requires at least two parallel approaches: pathway

construction for product generation and strain engineering for product accumulation. A starting

point for pathway construction is consideration of enzymatic reactions that can produce desired

aldehydes from cellular metabolites. Carboxylic acids are found throughout cellular metabolism

and many can be converted to aldehydes with the aid of a single enzyme. Prior to the detailed

characterization and cloning of enzymes capable of broadly catalyzing aldehyde formation,

various natural organisms ranging from actinomycetes to white rot fungi were tested for innate

ability to convert carboxylic acids into their corresponding aldehydes or alcohols (17-21). A

significant advance occurred roughly one decade ago, when a carboxylic acid reductase (CarNi)

from Nocardia iowensis was cloned into Escherichia coli and shown to be active on several

aromatic carboxylic acids in vitro (22). Later publications from Rosazza and colleagues

demonstrated that CarNi requires one-time activation by a phosphopantetheinyl transferase and

that CarNi has activity in vitro on a broader range of substrates that includes several citric acid

cycle dicarboxylic acids (23, 24). A homolog of CarNi from Mycobacterium marinum was

demonstrated to have activity on straight-chain aliphatic acids ranging from C6-C18 (25). A recent

review describes a larger number of carboxylic acid reductases that could be harnessed for

15

biosynthesis of a variety of aldehydes (26). The general stoichiometry for reactions catalyzed by

carboxylic acid reductases is as follows (where "e" represents a reducing equivalent):

R-COOH + e- + ATP

-

R-CHO + AMP + PPi

Aliphatic aldehydes across a broad range of carbon lengths can also be formed by using

fermentative aldehyde reductases or by using enzymes that act on activated forms of carboxylic

acids (acyl-CoA or acyl-ACP). During anaerobic cultivation of E. coli, conversion of acetyl-CoA to

acetaldehyde is catalyzed by a CoA-dependent acetaldehyde dehydrogenase (also known as

acetaldehyde CoA dehydrogenase) (27). However, the same protein, encoded by adhE, has a

second catalytic site that converts acetaldehyde into ethanol (28). In solvent-producing clostridial

strains, acetaldehyde and butyraldehyde can be produced by CoA-acylating aldehyde

dehydrogenases that are found as individual enzymes or as bifunctional enzymes (29-32). The

conversion of acyl-CoA to aldehyde is as follows (for acyl-ACP substrates instead of acyl-CoA

substrates, replace "S-CoA" and "CoASH" with "ACP"):

R-CO-S-CoA + e- 4 R-CHO + CoASH

Synthesis of longer carbon-chain aliphatic aldehydes from acyl-ACP precursors can occur

using enzymes from luminescent bacteria. In these bacteria, the multienzyme fatty acid

reductase complex consisting of luxCDE is used to produce aldehydes that are immediate

substrates for the light emission reaction (33). Note that the aldehyde biosynthetic reactions

discussed so far use similar chemistries that primarily differ in the source of reducing equivalents

and whether the carboxylic acid molecule or the reductase enzyme is activated first. In either

16

case, activation requires the conversion of ATP to AMP and pyrophosphate and occurs because

the energetics of converting a carboxylic acid to an aldehyde are ordinarily unfavorable.

Another set of non-oxidative aldehyde biosynthetic routes utilizes decarboxylation of 2keto acid substrates. In these cases, no ATP is required because the irreversibility of CO 2

formation provides the driving force for aldehyde formation. However, one carbon atom is lost

per molecule of 2-keto acid substrate, which reduces the theoretical maximum yield. Two wellknown enzymes in this category are pyruvate decarboxylase (PDC) and 2-ketoisovalerate

decarboxylase (KivD). The native role of PDCs are to convert pyruvate to acetaldehyde, but their

promiscuity and capability to catalyze carboligation side reactions has led to their use in synthesis

of chiral carboligation products (12). KivD is also promiscuous and has been utilized for synthesis

of numerous non-natural alcohols derived from amino acid intermediates (34). The 2-keto acid

decarboxylation reaction is as follows:

R-CO-COOH 4 R-CHO + CO 2

Oxidative reactions can also be used for aldehyde synthesis, starting from either

carboxylic acid substrates or primary alcohol substrates. C,, fatty acids can be converted to C,fatty aldehydes, as was shown using E. coli resting cells that expressed an a-dioxygenase from

Oryza sativa (rice) (35). In this case, spontaneous decarboxylation of a C, hydroperoxy fatty acid

intermediate provides a driving force for aldehyde generation. The dioxygenase-catalyzed

reaction is as follows:

R-CH 2-COOH

+ 02

4 R-CHO + CO 2 + H 2 0

17

In addition, aldehydes can be obtained by enzymatic oxidation of primary alcohols (3639). From a de novo aldehyde synthesis perspective, these reactions are less relevant given that

alcohols are typically produced via aldehyde intermediates. However, biocatalytic conversion of

primary alcohols to aldehydes may provide an array of new opportunities for alcohols as starting

materials and will be revisited later in this chapter. Oxidation of alcohols to aldehydes generates

a reducing equivalent as follows:

R-CH 2-OH -* R-CHO + e-

Natural and engineered pathways could be used to produce useful aldehydes from simple

carbon sources via their corresponding carboxylic acids. Pathway selection leading to the relevant

carboxylic acid precursor depends on the category of target aldehyde. Fig. 1-1 illustrates known

aromatic and aliphatic acid biosynthesis pathways that can be engineered to result in several

familiar flavors and fragrances. In the case of vanillin, which has the largest annual market volume

of any flavor compound, previous reports have described engineered heterologous pathways

that use the natural aromatic amino acid precursor 3-dehydroshikimate as a branch-point

metabolite to the heterologous reactions (40, 41). Frost and coworkers constructed a system to

produce vanillin from glucose that used an engineered strain of E. coli to produce vanillate from

glucose, followed by extraction and reduction of vanillate to vanillin in vitro using purified

carboxylic acid reductase from Neurospora crassa (40). De novo biosynthesis of vanillin and

vanillin-p-D-glucoside was first demonstrated

in both Saccharomyces cerevisiae and

Schizosaccharomyces pombe and has since been optimized using flux balance analysis (41-43). In

initial reports, titers of de novo vanillin-p-D-glucoside were roughly 50 mg/L in batch flask cultures

18

(41) and 500 mg/L in 1.5 L continuous cultures (42). The company Evolva has improved and

commercialized this process (16).

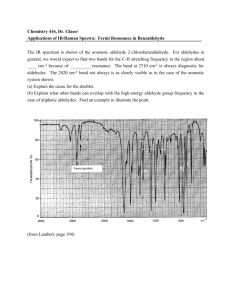

Glucose

Pentose Phosphate Pathway

Glycolysis

Aromatic Amino Acid Synthesis

Arom 3tic aldehydes

A~%~

TCA

Cycle

I

Omo

Fatty Acid Synthesis

Aliphatic aldehydes

Figure 1 - 1. Overview of natural metabolic pathways that can be harnessed for the conversion

of glucose to valuable aromatic and aliphatic aldehydes through carboxylic acid intermediates

based on E. coli metabolism. Aldehydes can also be obtained from the 2-keto acid pathway,

terpenoid pathways, and other pathways.

19

Among flavor compounds, benzaldehyde has the second largest annual market volume

after vanillin (44). Aromatic amino acid biosynthesis could also be used to engineer a microbial

pathway to benzaldehyde, potentially from phenylalanine as the starting endogenous

metabolite. Formation of benzaldehyde was reported after phenylalanine addition to cell extract

of Lactobacillus plantarum (45). In plants, benzaldehyde is derived from phenylalanine,

potentially from 1-oxidative and non-1-oxidative pathways (46). Recent work has uncovered key

steps in the P-oxidative pathway that can lead to synthesis of benzoate, which could serve as the

precursor to benzaldehyde in an engineered microbial pathway (47).

Aliphatic aldehydes can be obtained using pathways that result in free fatty acids (FFAs).

Although microbial FFAs have been produced for decades, recent work has demonstrated the

potential for obtaining advanced fuels or valuable chemicals as derivatives of FFAs (48-51).

Addition of suitable carboxylic acid reductases could potentially result in production of C4-C18

aliphatic aldehydes. Microbial synthesis of other valuable aldehyde classes, such as terpenoid

aldehydes, could potentially occur in E. coli using variations of previously engineered terpenoid

pathways (52).

As mentioned earlier, commercial entities have actively pursued aldehyde biosynthesis

routes using engineered microbes. Table 1-1 contains an overview of relevant published

aldehyde biosynthesis patent applications during the past 30 years. These patents were grouped

into three types of dominant routes of aldehyde biosynthesis. Although the third category (i.e.,

engineered microbes) pertains most to the topic of this thesis, the other two categories of

processes were included to provide context and perspective into chronological trends. For

example, during the 1980s and 1990s, industry patents on biotransformation processes featured

20

either isolated microbes or fruit homogenates. Commercial processes featuring fully de novo

aldehyde synthesis using engineered microbes appear to emerge only within the last decade. Of

course, an overview of patent literature does not account for industrial advances that were

retained as trade secrets.

21

NMI

Table 1 - 1. Relevant published aldehyde biosynthesis patent applications.

Dominant

Aldehyde

Applicant

Publicatio

n Date

Publication

Number

Patent Name

Relevant Claims

Grant (G) or

Application (A)

Takasago

Perfumery

Sep 6,

1988

US 4769243

A

Method for preparing

green aroma compounds

Use of ground soybeans to convert unsaturated

fatty acids to aliphatic aldehydes and alcohols

G

General Foods

Corporation

Feb 21,

1989

US 4806379

A

Process for producing a

green leaf essence

Use of strawberry homogenate to convert

linolenic acid to cis-3-hexanal and related

aldehydes

G

BASF

Oct 17,

1989

US 4874701

A

Preparation of

coniferylaldehyde by a

microorganism

Use of Arthrobacter globiformisDSM 3597 to

convert n-eugenol to coniferylaldehyde

G

Haarmann &

Reimer Gmbh

May 21,

1991

US 5017388

Process for the

preparation of vanillin

Use of certain species from the genera Serratia,

Klebsiella, or Enterobacter to convert eugenol or

isoeugenol to vanillin

G

Kraft General

Foods

Jul 7, 1992

US 5128253

A

Bioconversion process for

the production of vanillin

Use of ferulic acid degrading microorganisms

such as Aspergillus niger, Rhodotorula glutinis, or

Corynebacterium glutamicum to convert ferulic

acid to vanillin

G

Firmenich

Nov 7,

1995

US 5464761

A

Process for the enzymatic

preparation of aliphatic

alcohols and aldehydes

from linoleic acid or a

natural precursor

Use of lipoxygenase-containing soya flour and

lyase-containing guava homogenate to convert

linoleic acid to hexanal and related aldehydes

G

BASF

May 19,

1998

US 5753471

A

Biotechnological

preparation of alcohols,

aldehydes, and carboxylic

acids

Use of isolated microorganisms capable of

converting alkyl, alkenyl, aryl, and related

compounds to their oxidized forms, including

aldehydes

G

Biosynthesis Route

Biotransformation

using

homogenates or

natural

microorganisms

_________________________________________________ J___________________________________________________________________________________________

L

I._____________________________

22

using purified

carboxylic acid

reductases

De novo synthesis

using engineered

microbes

harboring

recombinant

aldehyde

biosynthetic genes

(e.g., car, aar, kivD)

University of

Iowa

Aug 18,

1998

US 5795759

A

Carboxylic acid reductase,

and methods of using

same

A purified carboxylic acid reductase (Car) enzyme

from Nocardia iowensis, and use of it to convert

Synthesis of vanillin from

a carbon source

Use of an engineered microbe expressing

recombinant DHSD and COMT as part of a

metabolic pathway from glucose to vanillic acid,

followed by reduction of vanillic acid to vanillin

using a purified Car

G

G

vanillic acid to vanillin

Michigan State

University

Apr 16,

2002

US 6372461

University of

Iowa

Sep 16,

2008

US 7425433

B2

Carboxylic acid reductase

polypeptide, nucleotide

sequence encoding same

and methods of use

Use of Car to convert aromatic, aliphatic, and

acyclic carboxylic acids to corresponding

aldehydes

G

Archer-Daniels-

Feb 17,

US 7491854

2009

B2

Enzymatic method of

making aldehydes from

fatty acids

Use of Car to convert fatty acids ranging from C6C32 to corresponding aldehydes

G

Midland

DuPont

Aug 29,

2006

US 7098000

B2

Method for production of

Use of an engineered microorganism to convert

fermentable carbon sources to

diaponeurosporene monoaldehyde,

diapocarotene monoaldehyde, or diapocarotene

dialdehyde

G

Jan 17,

US 8097439

Methods and

Use of engineered microbes containing

G

2012

B2

compositions for

recombinant Car homologues to convert

producing fatty aldehydes

carbohydrates to aliphatic aldehydes

LS9

B1

C30-aldehyde

carotenoids

LS9

Sep 18,

2012

US 8268599

B2

Method for producing a

fatty alcohol or fatty

aldehyde

Use of acyl-ACP reductases to convert acyl-ACPs

to aliphatic aldehydes

G

International

Flavors

Fragrances,

Evolva

Feb 14,

WO 201302

2881 Al

Compositions and

methods for the

biosynthesis of vanillin or

Use of a microbe expressing recombinant AROM

and/or COMT to convert glucose to vanillin or

vanillin-beta-d-glucoside

A

2013

&

In vitro conversion

of acid substrates

vanillin-beta-d-glucoside

23

-

University of

California

T

Dec 27,

2013

T

WO 201319

T

2237 Al

Escherichia coli

engineered for

isobutyraldehyde

7

Use of an E. coli strain with reduced

isobutyraldehyde reductase activity to

accumulate isobutyraldehyde

A

production

Easel

Biotechnologies

Jan 9,

2014

US

2014001123

1 Al

Microbial synthesis of

aldehydes and

corresponding alcohols

Use of an engineered microbe to convert glucose

to short fatty aldehydes, followed by removal of

aldehydes from the fermentation medium and

conversion to alcohols ex vivo

A

Genomatica

Apr 24,

2014

WO

2014062564

Al

Microorganisms and

methods for production

of specific length fatty

alcohols and related

compounds

Use of a microbe expressing malonyl-CoA

independent (or dependent) fatty acyl-CoA

elongation pathways to produce fatty acids,

aldehydes, and alcohols

A

Evolva

Sep 4,

US

2014024866

Methods and materials

for recombinant

production of saffron

compounds

Use of a microorganism expressing recombinant

pathways to convert glucose to picrocrocin,

safranal, crocin, crocetin, or crocetin esters

A

2014

8 Al

I ________

I _________

I.

L __________________________________

___________

24

1.3. Minimizing endogenous conversion of aldehydes to alcohols

Despite known routes to a variety of aldehydes, microbial aldehyde production is

hindered by the rapid endogenous conversion of nearly all aldehydes to their corresponding

alcohols. For example, when expression of recombinant CarNi was first reported in E. coli,

aromatic acids supplied to culture media were rapidly converted into aromatic alcohols (22). Even

in E. coli, the most genetically well-understood organism, numerous uncharacterized genes were

thought to contribute to this activity. It is worth highlighting here that although oxidation of an

aldehyde to a carboxylic acid is thermodynamically more favorable than reduction of a carboxylic

acid to an aldehyde, endogenous aldehyde oxidation does not appear to be significant for most

aldehydes of interest in model microbes. On the other hand, endogenous aldehyde reduction has

been thoroughly documented in the literature.

In 2012, Rodriguez and Atsumi reported accumulation of isobutyraldehyde in E. coli by

sequentially deleting eight genes encoding putative isobutyraldehyde reductases (yqhD, adhP,

eutG, yiaY, yjgB (now ahr), betA, fucO, and eutE) (53). When individually overexpressed, five of

these genes displayed activity toward isobutyraldehyde. The engineered deletion strain

increased isobutyraldehyde production from 0.14 g/L/OD 6oo to 1.5 g/L/OD6oo and decreased

isobutanol production from 1.5 g/L/OD6oo to 0.4 g/L/OD6oo. Although isobutanol formation still

occurred, this study suggested that the number of gene deletions required to mitigate conversion

of a particular aldehyde may be a manageable quantity. A major goal of the research documented

in this thesis is to elucidate the number of relevant aldehyde reductases for other model

aldehydes, starting with benzaldehyde.

25

..

............

1.4. Enhancing bioconversion of aldehydes to other chemical classes

Microbial aldehyde accumulation is expected to enable biosynthesis of several previously

problematic compounds that can be derived enzymatically from aldehyde intermediates (Fig. 12). One aldehyde-derived molecule of interest is L-phenylacetylcarbinol (L-PAC), a chiral

precursor to the pharmaceutical ephedrine (12-15). Although whole cell catalysts have been used

for L-PAC synthesis for a long time, significant benzyl alcohol byproduct formation occurs from

their use, resulting in low yields (12). In addition to PDC, other enzymes capable of catalyzing

chiral carboligations of aldehyde substrates have been discussed (54).

0

R

R

H

aldehydes

as products

alkanes

0

0

reductionl

----- -----

reductiot

+

cellular

metabolites

OH

R)

R

oxidation

carboxylic acids

R

aldehydes

OH

oxidato

alcohols

OH

R

R

R

NH2

primary amines

0

chiral condensations

other potential aldehyde-derived products:

- nitroalcohols;

-

OH

R

esters

- 13-amino-carbonyls

chiral cyanohydrins

Figure 1- 2. Potential biocatalytic and metabolic engineering opportunities that could be enabled

by, or enhanced by, microbial aldehyde accumulation.

26

A similar challenge of limiting unwanted flux from aldehyde intermediates to alcohol

byproducts has been encountered in the context of alkane production. The final step to alkane

biosynthesis features the conversion of a C,, aldehyde to a C,,- alkane catalyzed by an aldehyde

decarbonylase or aldehyde deformylating oxygenase (25, 55-59). Although the problem of

alcohol byproduct formation has been described extensively, very few reports of alkane

biosynthesis have used strains engineered with deletions of aldehyde reductases. A later chapter

in this thesis will investigate the ability to reduce alcohol byproduct formation and the resulting

effect on alkane titers.

In addition to chiral carboligations and decarbonylations, aldehyde substrates can

participate in numerous other enzyme-catalyzed reactions (Fig. 1-2); for example, transamination

to form primary amines (60, 61), hydrocyanation to form chiral cyanohydrins (62), Henry

reactions to form nitroalcohols (63), Baeyer-Villager oxidation to form esters (64), and Mannich

reactions to form 0-amino-carbonyl compounds (65, 66). Some of the aforementioned reactions

have already been demonstrated to be functional in a cellular context using resting E. coli cells

(62, 67). Microbial aldehyde accumulation would enable potential synthesis of these compounds

using metabolically-active cells that can supply and regenerate expensive cofactors. Synthesis of

some of these products may also be achieved using glucose or other simple sugars as the sole

carbon source. In addition, biocatalytic oxidation of exogenously supplied alcohols (37-40, 64,

72) would be more effective in the absence of aldehyde reduction. In theory, any of the classes

of aldehyde-derived compounds enabled in the absence of aldehyde reduction could also be

obtained directly from the corresponding primary alcohols using a single engineered microbe.

1.5. Addressing aldehyde toxicity

27

If microbial aldehyde accumulation could be engineered, the next impediment to

consider would be aldehyde toxicity. Observable toxicity is manifested by inhibition of microbial

growth in the presence of aldehydes, but morphological changes have also been reported (68).

In most cases, the extent of toxicity seems to depend on the aldehyde but may also depend on

the choice of microorganism. Cinnamaldehyde, for example, is known to be a potent

antimicrobial (69). In the case of vanillin, Zaldivar et. aL. found that 1.5 g/L of vanillin completely

inhibited growth of the E. coli strains examined (68). The same study investigated the effect of

exposing E. colito several representative aromatic aldehyde products of hemicellulose hydrolysis

and found that toxicity was directly related to the hydrophobicity of the aldehyde. The

relationship with hydrophobicity suggested that a hydrophobic target, such as the cell

membrane, may be involved. However, none of these aldehydes caused sufficient membrane

damage to allow the leakage of intracellular magnesium (68). Another study investigated the

toxicity of four aldehydes (furfural, 5-hydroxymethylfurfural, vanillin, and syringaldehyde) on

Candida tropicalis and found that vanillin was the most toxic, followed by syringaldehyde,

furfural, and 5-hydroxymethylfurfural (70). The influence of the structural elements of vanillin

and related compounds on antifungal activity has also been examined and differences in

antifungal activity were found (71). However, when the effect of five aldehydes on the growth of

the oleaginous yeast Trichosporon fermentans was investigated, no relationship was found

between the hydrophobicity and toxicity of the aldehyde (72).

The E. coli strains investigated by Zaldivar et. aL. were not engineered to have minimal

aldehyde reductase activity, and later studies from the same group suggested that growth

inhibition may be caused by NADPH consumption resulting from aldehyde reduction (73, 74).

28

Two genes (dkgA and yqhD) were found to be silenced in an evolved furfural-resistant strain.

Expression of these genes, which encode enzymes with low KM values for NADPH, decreased

furfural tolerance (73). In a separate investigation, transcriptome data was analyzed before and

after exposure to furfural. Several lines of evidence suggested that cysteine and methionine

biosynthesis was upregulated in order to combat a limitation in sulfur assimilation due to NADPH

depletion (74).

A deeper understanding of precisely how aldehydes cause harm to cells may enable

engineering strategies to surmount particular modes of toxicity. Certain aldehydes may be

involved in far more detrimental mechanisms of toxicity than others. For example, acetaldehyde

has been shown to induce single-strand and double-strand breaks in DNA (75). Several aliphatic

aldehydes are products of lipid peroxidation and have been implicated in forming adducts on a

variety of biological macromolecules and as second messengers of reactive oxygen species (ROS)

(76-78). However, the precise relationship between aldehydes and ROS is unclear. For example,

it was recently shown that resistance of E. coli to exogenous methylglyoxal is conferred by

decreased expression of sodC(79). This is a surprising result given that sodCencodes a superoxide

dismutase, which breaks down ROS (80). There are numerous other potential mechanisms of

aldehyde toxicity. Given the importance of lignocellulose utilization, potential mechanisms of

toxicity for furfural in particular have been extensively reviewed and include mechanisms not

described here (81, 82).

Until precise mechanisms of aldehyde toxicity are elucidated, there are some general

engineering strategies that can be employed. Some bacteria naturally evolved solutions to

aldehyde toxicity beyond rapid reduction of aldehydes, such as protein microcompartments that

29

feature aldehyde intermediates (83, 84). If control of selective metabolite transport through the

protein shells were achieved, then the engineering of these compartments for biosynthesis of

new aldehyde-derived products may aid in limiting the pool size of free aldehyde intermediates

(85). Independent of the mode of toxicity, in situ separation using stripping (86), two-phase

systems (87), or selective resins (88) may result in increased production of aldehydes as end

products. Many aldehydes of interest are hydrophobic and volatile, which are properties that aid

separation from aqueous-based fermentation processes. In the event that precise mechanisms

of aldehyde toxicity become known and prove to be insurmountable, then efforts should shift

towards microbial engineering of aldehyde intermediates for synthesis of aldehyde-derived

products. In addition, the issue of aldehyde toxicity can be circumvented entirely with the use of

a cell-free or in vitro biosynthetic process, which is a topic that Chapter 4 of this thesis will

explore.

1.6. Thesis organization

The work documented in this thesis sought to answer a relatively orderly set of questions

motivated by Chapter 1 and by results from later chapters. Chapter 2 begins by exploring the

question of whether endogenous reduction of two simple aromatic aldehydes in E. coli can be

decreased using a series of gene deletions. If so, then what might the contributions of these genes

be towards the overall native level of endogenous aromatic aldehyde reduction? In addition,

Chapter 2 asks whether the decreased endogenous aromatic aldehyde reduction could be useful

for metabolic engineering or biocatalytic applications in the flavor and pharmaceutical industries,

such as biosynthesis of vanillin from glucose or biosynthesis of L-phenylacetylcarbinol from

glucose and exogenously supplied benzaldehyde. Given the ability of the engineered host strain

30

to accumulate both aromatic aldehydes tested, Chapter 3 poses the question of whether the

same genes targeted for deletion mightgovern the reduction of structurally unrelated aldehydes,

such as aliphatic aldehydes. If so, then could the same engineered host strain be used to reroute

aliphatic aldehydes to n-alkanes instead of primary alcohols, given that the former class of

biofuels are more compatible with current petroleum and automobile infrastructure? Next,

Chapter 4 examines how effectively aldehyde biosynthesis can occur outside of the cell using

purified enzymes. Previously, the use of carboxylic acid reductases to produce aldehydes in vitro

has been hampered by limited turnover. Chapter 4 provides some insight into why this

phenomenon occurs and explores the possibility of in vitro aldehyde biosynthesis as an

alternative to microbial aldehyde biosynthesis given that it completely circumvents the problem

of product toxicity. Providing a foundation for future metabolic engineering efforts, Chapter 5

returns to de novo biosynthesis of the model aldehyde vanillin using E. coli and seeks to

understand what biochemical reaction steps in the engineered pathway limit vanillin production.

Finally, Chapter 6 synthesizes lessons learned along the graduate research journey and

documents potential areas for further investigations.

31

Chapter 2: Engineering synthesis and accumulation of aromatic aldehydes in E.

coli

Portions of this chapter are adapted from the following manuscript: Kunjapur et al (2014), J. Am.

Chem. Soc., 136 (33) 11644-11654. Results presented were obtained with the help of Yekaterina

Tarasova.

2.1. Introduction

Chapter 1 discussed applications of numerous aldehydes and aldehyde-derived products.

Based on ease of detection and commercial relevance, aromatic aldehydes were initially focused

on for this thesis. Two model aromatic aldehydes are benzaldehyde, which is structurally the

simplest aromatic aldehyde, and vanillin. Biotechnological production of vanillin is of special

interest given that less than 1% of the 16,000 tons of vanillin sold annually originates from vanilla

beans (89). Due to the limited supply and high price of extract from the vanilla bean, most of the

market consists of vanillin that is chemically synthesized from either lignin or petroleum.

Consumer preference for flavors in which no chemicals are used [i.e., natural flavors (90)] has led

to a price differential of $1,200-$4,000/kg for natural vanillin compared to $15/kg for artificial

vanillin (89).

As discussed in Chapter 1, the primary barrier to overproduction of aromatic aldehydes

in engineered microorganisms is the rapid conversion of desired aldehydes into undesired

alcohols by numerous endogenous enzymes (41, 91). Several factors motivate the selection of E.

coli for identification and deletion of genes that encode aromatic aldehyde reductases. The

superior tools and know-how established with this organism enable rapid evaluation of gene

32

targets. Strategies to increase flux from central metabolism to the biosynthesis of aromatics in E.

coli are well-documented (92-95) and thus expected to facilitate swift improvements in aromatic

aldehyde production if their accumulation were realizable. Furthermore, E. coli K-12 strains have

been used to produce food additives designated as GRAS (Generally Recognized As Safe), such as

chymosin (96). Knowledge of the E. coli genes responsible for aromatic aldehyde reductase

activity can also help inform efforts to engineer other microbial hosts.

In this chapter, we describe how we began this endeavor by exploring serial deletions of

different combinations of genes that were reported to act on benzaldehyde, which is structurally

the simplest aromatic aldehyde. Our search initially focused on aldo-keto reductases (AKRs),

which form a superfamily of enzymes that have broad substrate specificity and convert aldehydes

and ketones to alcohols in the presence of NADPH (97). In the few previously reported attempts

at constructing microbial pathways to produce aldehydes, only genes encoding alcohol

dehydrogenases (ADHs) were targeted for deletion (41, 53). Unlike AKRs, ADHs typically use

NADH as their co-factor, and under anaerobic conditions they perform the important function of

recycling co-factors. We hypothesized that rational deletion of AKRs with activity on

benzaldehyde, in addition to the deletion of select ADHs, would be a promising route to

engineering the accumulation of aromatic aldehydes in E. coli. After pursuing this strategy, we

report the construction of an E. coli MG1655 strain with reduced aromatic aldehyde reduction

(RARE) that can serve as a platform for the synthesis of aromatic aldehydes with minimal or no

conversion to their corresponding alcohols. This chapter concludes with the use of the RARE

strain to enable the synthesis of vanillin and L-PAC, demonstrating the utility of this particular

33

engineered strain and the general approach of rationally combining gene knockouts to overcome

a highly redundant endogenous activity.

2.2. Materials and Methods

2.2.1. Strains and plasmids

E. coli strains and plasmids used in this study are listed in Table 2-1. Molecular biology

techniques were performed according to standard practices (98) unless otherwise stated.

Molecular cloning and vector propagation were performed in DH5a. All targeted genes were

deleted from E. co/i K-12 MG1655(DE3). The genes dkgB, yeaE, yahK, yjgB, endA, and recA were

deleted using donor strains from the Keio collection (99) and P1 transduction (100). P1

bacteriophage was obtained from ATCC (25404-B1). The operon encoding yqhC-dkgA was

deleted using the A Red system (101). To generate homology, three pairs of oligonucleotides were

used as PCR primers. These and other oligonucleotides are shown in Table 2-2. Oligonucleotides

were purchased from Sigma. Q5 High Fidelity DNA Polymerase (New England Biolabs) was used

for DNA amplification. In all cases of gene deletions, pCP20 was used to cure the kanamycin

resistance cassette (101).

34

Table 2 - 1. Strains and plasmids used in this study.

Invitrogen

DH1OB

I- WULIaCAM15 A(IaCZYA-argF) U169 recAl endAl fSGR17 (rK-,

mK+) phoA supE44 X- thi-1 avrA96 reIA1

F-mcrA A(mrr-hsdRMS-mcrBC) (D80acZAM15 AIacX74 recAl endAl

araDl39A(ara,leu)7697 galU galK k rpsL nupG

MG1655

MG1655(DE3)

F k ilvG- rfb-50 rph-1

F k iIvG- rfb-50 rph-1 (DE3)

ATCC 700926

Ref. (102)

MG endA- recA-

MG1655(DE3) AendA ArecA

Ref. (103)

JW0197-1

JW1770-5

JW0317-1

JW5761-1

JW2912-1

BW26547

Subset 1

(AMKO01)

Subset 2

(AMKO02)

RARE endArecA- (AMK003)

AMKO04

AMKOO5

AMKO06

AMKO07

AMKO08

AMKO09

AMK010

AMK011

AMK012

AMKO13

AMK014

Subset 3

(AMKO16)

AMKO17

RARE

(AMKO18)

AMKO19

Subset 4

(AMK035)

AMK036

RARE endA- recAvanillin

MG endA- recAvanillin

AdkgB726::kan

AyeaE778::kan

AyahK767::kan

AyjgB740::kan

ArecA635::kan, recA+

MG1655(DE3) AdkgB AyeaEAyahKAyjgB

CGSC 12026

CGSC 9486

CGSC 8516

CGSC 11992

CGSC 10253

CGSC 7652

This study

MG1655(DE3) A(yqhC-dkgA)::kan

This study

dendA720::kan

MG1655(DE3) AdkgB AyeaEA(yqhC-dkgA) AyahK AyjgB AendA

Invitrogen

ArecA

This study

AMK0O3 harboring pETDuet-1 and pACYC-car-sfp

AMKO01 harboring pETDuet-1 and pACYC-car-sfp

AMKO02 harboring pETDuet-1 and pACYC-car-sfp

AMKO03 harboring pET-dkgB and pACYC-car-sfp

AMKO03 harboring pET-yeaE and pACYC-car-sfp

AMKO03 harboring pET-yahK and pACYC-car-sfp

AMKO03 harboring pET-yjgB and pACYC-car-sfp

AMKO03 harboring pET-yqhC and pACYC-car-sfp

AMK003 harboring pET-yqhD and pACYC-car-sfp

AMK003 harboring pET-dkgA and pACYC-car-sfp

MG1655(DE3) AendA ArecA harboring pETDuet-1 and pACYC-car-sfp

MG1655(DE3) AdkgB AyeaE A(yqhC-dkgA)::kan

This study

This study

This study

This study

This study

This study

This study

This study

This study

This study

This study

This study

MG1655(DE3) AdkgB AyeaE

MG1655(DE3) AdkgB AyeaE A(yqhC-dkgA) AyahK AyjgB

This study

This study

AMKO16 harboring pETDuet-1 and pACYC-car-sfp

MG1655(DE3) A(yqhC-dkgA) AyahKAyjgB::kan

This study

This study

AMK035 harboring pETDuet-1 and pACYC-car-sfp

AMKO03 harboring pET-OMT-asbF and pACYC-car-sfp-aroG*

This study

This study

MG1655(DE3) AendA ArecA harboring pET-OMT-asbF and pACYCcar-sfp-aroG*

This study

35

RARE

pRSF/PDCE473Q

RARE

pRSF/PDCE473Q

pACYC/Car/Sfp

MG

pRSF/PDCE473Q

pACYC/Car/Sfp

AMKO03 harboring pRSF/PDCE473Q

This study

AMKO03 harboring pRSF/PDCE473Q and pACYC-car-sfp

This study

MG1655(DE3) AendA ArecA harboring pRSF/PDCE473Q and pACYCcar-sfp

This study

pCP20

pKD13

Xc1857 (ts), X pr Repts, AmpRJ

CGSC 7629

CGSC 7633

pKD46

pETDuet-1

CGSC 7739

Novagen

pRSFDuet-1

oriR101, repA1O1, AmpR, araC, araBp-AyAe-Aexo

AmpR, lad, T7/ac

CmR, lac, T7iac

KanR, lad, T7/ac

pACYC-car-sfp

pACYCDuet-1 harboring caropt (carboxylic acid reductase from

This study

pACYCDuet-1

CmR, A pr FLP

oriRy, AmpR, kan