Pre-rotation Drive Upgrade

Reduce energy consumption on

“S-type” compressors

Energy savings between 6 - 15% are not

uncommon when upgrading an S-type

HV-Turbo compressor with a variable inlet

guide vane system (type SV).

The achievable savings depend on local

conditions and individual plant structures,

however under these operating conditions

you will benefit mostly from an upgrade:

Where you have variation in the inlet air

temperature

Where you have variation in the

required outlet air pressure

Where you have variation in the

required air flow

Key advantages

Potential for substantial energy savings

Return on investment can be as low as 1

to 2 years

Process improvements through new

optimized regulation system

High degree of automation is possible

reducing the need for operator

intervention

All of the above is of highest interest in a

market with ever rising energy prices and

environmental interest and awareness.

The SV upgraded compressor is capable of

self adjustment to different operating

conditions and will therefore operate with

high efficiency in a much broader

temperature, pressure and flow range.

Plant analysis

In order to estimate the savings potential

at your particular site we offer a cost &

efficiency analysis to be performed by our

skilled engineers. Following the cost &

efficiency analysis we will give our

recommendation to conclude whether an

upgrade would be beneficial for your plant.

If you can profit from an upgrade, we will

ork out an individual offer for you

adapting to your specific needs.

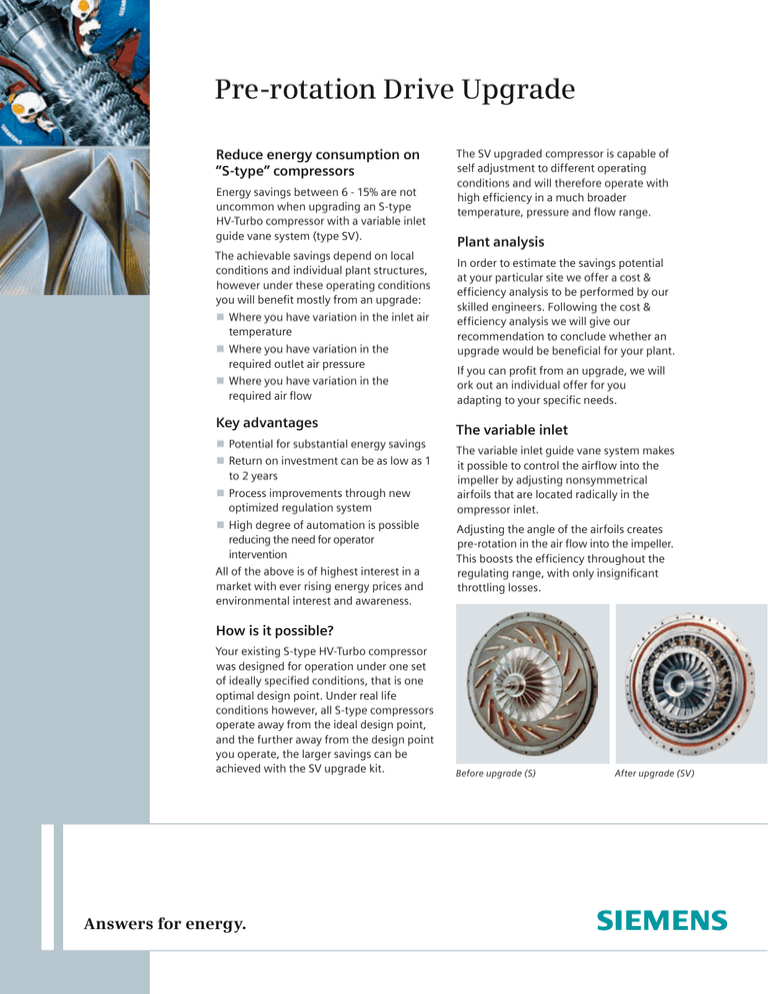

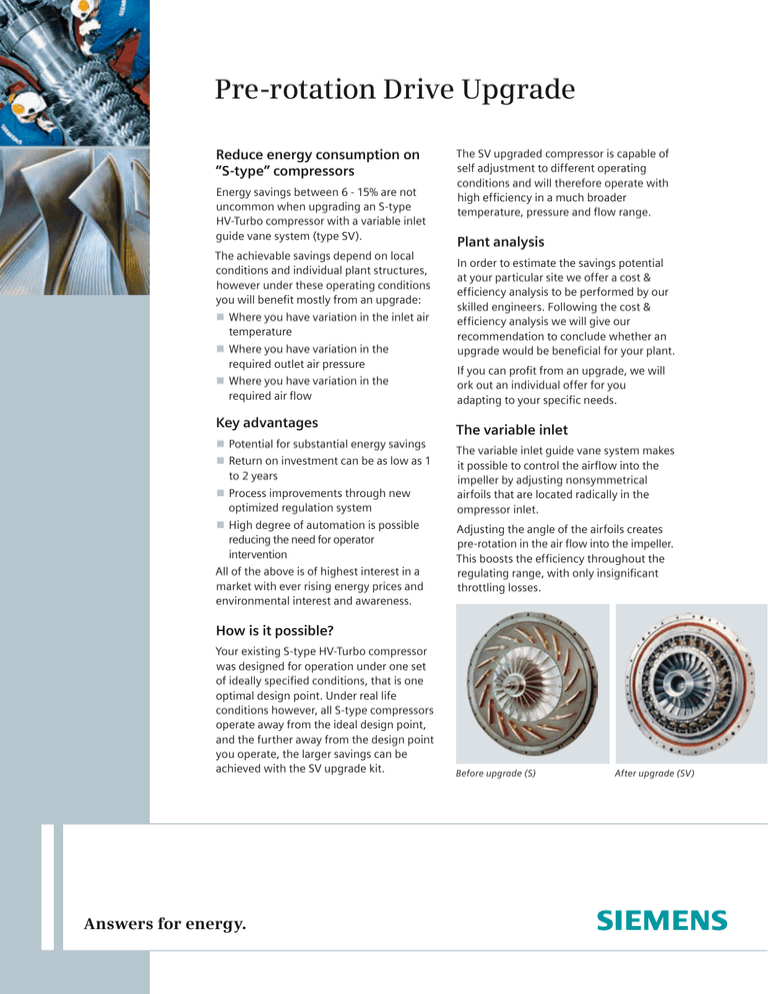

The variable inlet

The variable inlet guide vane system makes

it possible to control the airflow into the

impeller by adjusting nonsymmetrical

airfoils that are located radically in the

ompressor inlet.

Adjusting the angle of the airfoils creates

pre-rotation in the air flow into the impeller.

This boosts the efficiency throughout the

regulating range, with only insignificant

throttling losses.

How is it possible?

Your existing S-type HV-Turbo compressor

was designed for operation under one set

of ideally specified conditions, that is one

optimal design point. Under real life

conditions however, all S-type compressors

operate away from the ideal design point,

and the further away from the design point

you operate, the larger savings can be

achieved with the SV upgrade kit.

Answers for energy.

Before upgrade (S)

After upgrade (SV)

The upgrade

Other beneficial offerings when

upgrading

A typical upgrade will comprise of:

As your compressor would be upgraded

and tested in our works, it could be

beneficial to consider the following

additional options:

The variable inlet guide vane unit

A new local control panel

The latest software version for the

localcontrol panel

Complete inspection & service of the

compressor

A documented performance- and QA

test prior to shipping proving theoretical

calculated performance values

Refurbishment of your compressor

according to individual needs

One set of user documentation

The savings (exemplified)

Compressor type: KA10

310

300

40

Power consumption, S-type

35

Power consumption, SV-type

(with pre-rotationdrive)

Power consumption

(kW)

25

280

20

270

15

260

10

250

Average monthly air temperature

(Deg. C)

30

290

Inlet air temperature

(monthly avarage day temperature)

Energy saved

5

240

ar

nu

Ja

ry

ua

y

br

Fe

ch

ar

M

ril

Ap

ay

ne

Ju

M

ly

Ju

s

gu

Au

t

r

be

m

te

ep

S

er

b

to

Oc

r

r

be

be

m

ve

No

em

c

De

Month

The curves are based on the following

performance data:

Mass flow:

13,000 Nm3/hour

Discharge pressure: 1.7 bar

Published by and copyright © 2008:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Power Generation, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, contact our

Customer Support Center.

Phone:

+49 180/524 70 00

Fax:

+49 180/524 24 71

(Charges depending on provider)

e-mail: support.energy@siemens.com

www.siemens.com/energy

Operating haurs:

8,400 h/year

Under the preconditions given in this

example, the result will be:

Potential saving ~ 243,000 kWh/year

To learn more about the energy savings

pontential for your “S-type” compressor,

please contact our Customer Service or

your local Siemens representative.

Order No. A96001-S90-B286-X-4A00

Printed in Denmark

1386 P DA 0508 .5

All rights reserved.

Subject to change without prior notice.

Printed on paper treated with chlorinefree bleach.

Trademarks mentioned in this document are the property of Siemens AG,

its affiliates, or their respective owners.

The information in this document

contains general descriptions of the

technical options available, which may

not apply in all cases. The required

technical options should therefore be

specified in the contract.

For more information please contact:

Siemens A/S

Turbomachinery Solutions

Allegade 4

DK-3000 Helsingør

Denmark

Phone: +45 49 21 14 00

Fax: +45 49 21 52 25

At Siemens Turbomachinery

Solutions, we strive to provide the

best service to our customers.

Therefore, you will always get solutions

and service products designed to suit

your individual needs.

We can assist you with everything from

spare parts and training to refurbishment

and upgrades of old equipment and

maintenance of existing installations.

You can choose between a wide range

of service solutions:

On-site or off-site training

programmes

Process optimization consultancy

Refurbishment of existing

equipment

Service contracts relating to

equipment