DOWN BY THE RIVERSIDE

advertisement

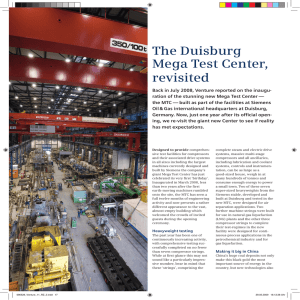

1 8 _ S P O T L I G H T Scaling up for Tomorrow’s Demand Driven by surging global demand and economies of scale, plants in the processing industries continue to grow in both size and complexity, whilst new paradigms and solutions are being developed to cope with future requirements. In Duisburg, Germany, Siemens are about to build a unique assembly and test facility for large-scale compressor trains. DOWN BY THE RIVERSIDE Air separation or air compression units are the single most important parts of many of these megaplants, notably of processes involving syngas production as an intermediate step. To a great extent the economies of such plants are determined by the performance and power requirements of the turbomachinery employed. The increase in compressor size and performance, however, necessitates massive complementary investments. One such investment is the facility for testing equipment prior to delivery. Such giant machine strings—comprising main and booster air compressors and driver—will require complete string-testing before being shipped and installed at customers’ sites. Unforeseen problems impacting on the project schedule would be a risk no one would willingly take. EXPANDING NEXT DOOR Representing an investment of 90 million euros, an assembly and test center unique for its size and versatility is currently being built in Duisburg, Germany, next to the Siemens Power Generation Industrial Applications headquarters and compressor manufacturing unit. The facility covers an area of 62,000 square meters, the equivalent of more than eight football pitches. Groundwork is under way, preparing for an estimated 20,000 cbm of concrete and 5,000 tons of steel to be deployed. Once completed, the test center will allow string-testing of mega-scale compression solutions for processes including GTL, LNG and electric LNG, as well as a range of applications in the chemical industry. Simultaneous assembly and testing is possible for up to eight compressor strings. Dedicated utilities allow testing with all relevant drive types, including variable and fixed-speed electric drives of up to 100 megawatt (MW), steam turbine powered strings at up to 100 bar, and gas turbine driven strings of up to 100 MW. The facility also allows gas turbine tests for the purpose of research and development. Test design will be in accordance with ASME PTC 10. Says Dr. Peter Langer, head of the compressor business in Duisburg: “Clearly, the new test and assembly facility will put Siemens in the vanguard of future mega-scale solutions. This investment represents a "megaboost" in our potential for delivering what the customer requires.” The assembly and test center will be completed in June 2007 and operational as of August 2007. CAD rendition of the assembly and test center for mega-scale compression solutions. Illustrations, left: Siemens; Photo, right: Florian Sander These days, few developments in engineering can be found that do not contain the emphasizer ‘mega’. As schemes for tomorrow’s GTL, CTL, LNG, IGCC, PTA, ethylene, methanol and olefin plants reveal, ‘megascale’ is what companies in the oil & gas and chemical industries are currently preparing for. And, naturally, so are developers and equipment suppliers. The test center location has been chosen not only for its vicinity to existing Siemens facilities. It also provides direct access to the river Rhine. As a result, shipping compressor strings for mega-scale applications no longer requires a first leg of transportation via public roads, with all its intrinsic hassle. Instead, the machines will be loaded directly on board a barge at Siemens’ own jetty, and float downstream to the Rotterdam Europoort to sail the seas. The vast majority of these big new machines is expected to be deployed at upstream locations around the world—in countries which attract the vast share of today’s investments in the process industry to build new GTL and LNG plants.