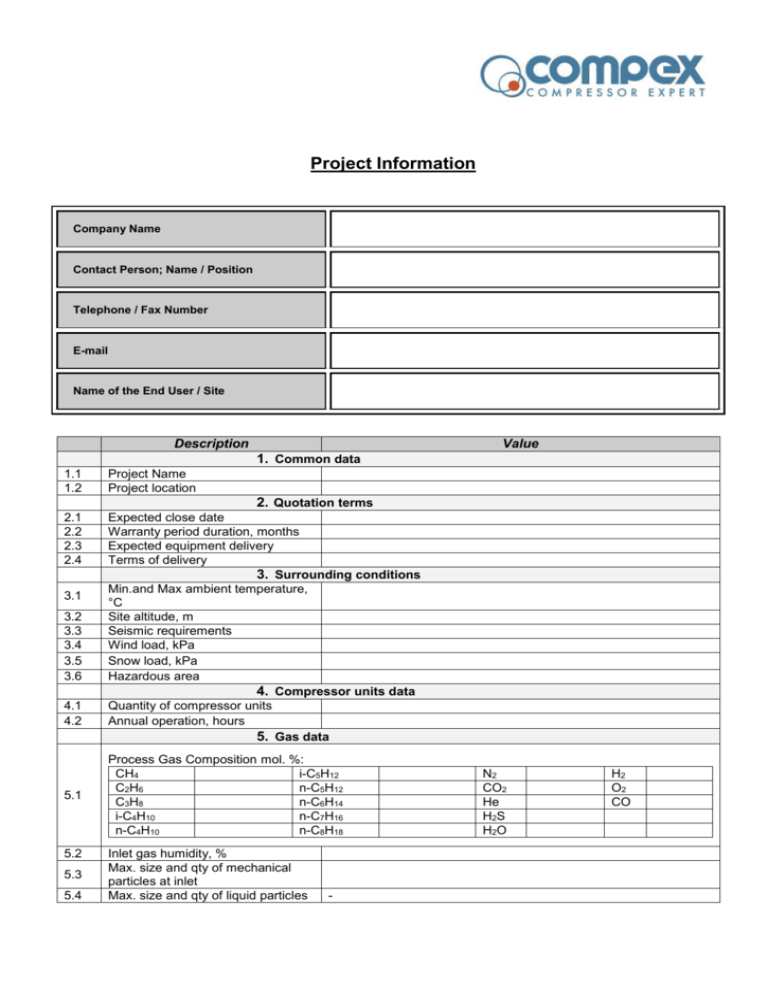

COMPEX Questionnaire

advertisement

Project Information Company Name Contact Person; Name / Position Telephone / Fax Number E-mail Name of the End User / Site Description Value 1. Common data 1.1 1.2 2.1 2.2 2.3 2.4 3.1 3.2 3.3 3.4 3.5 3.6 4.1 4.2 5.1 5.2 5.3 5.4 Project Name Project location 2. Quotation terms Expected close date Warranty period duration, months Expected equipment delivery Terms of delivery 3. Surrounding conditions Min.and Max ambient temperature, °C Site altitude, m Seismic requirements Wind load, kPa Snow load, kPa Hazardous area 4. Compressor units data Quantity of compressor units Annual operation, hours 5. Gas data Process Gas Composition mol. %: СН4 i-C5Н12 С2Н6 n-C5Н12 С3Н8 n-C6Н14 i-C4Н10 n-C7Н16 n-C4Н10 n-C8Н18 Inlet gas humidity, % Max. size and qty of mechanical particles at inlet Max. size and qty of liquid particles - N2 CO2 He H2S H2O H2 O2 СО Description 5.5 Value at inlet Maximum content of oil, ppm W at outlet 6. Process parameters 6.1 6.2 6.3 6.4 6.5 Gas inlet pressure min/max MPa, gauge Gas inlet temperature min/max, °C Gas discharge pressure, MPa (gauge) Gas outlet temperature,°C Gas Flow max (of one compressor unit), Nm3/h (0 ºС; 101,325 kPa absolute) 7. Equipment configuration 7.1 Compressor unit execution Indoor (without acoustic enclosure)___ Indoor (with acoustic enclosure)___ Outdoor___ Remote installation___ 7.2 Switchboards location Separate compartment of acoustic enclosure___ Electric motor____ Gas Engine____ 7.3 Compressors driven by 7.4.1 Main motor power supply, kV 7.4.2 Softstarter for main motor enquiry to be included_____ don`t needed_____ Valves drives type air ___ electircal ___ 7.7.1 Cooler type air___ water___ 7.7.2 7.7.3 7.7.4 7.7.5 7.7.6 Inlet water temp., °C Outlet water temp., °C Water inlet pressure, MPa gauge Flow rate, m3/h Water pH Water composition transparence - sm suspended solids – mg/l ammonium nitrogen – mg/l nitrite – mg/l oxidability – mg/O2 alkalinity – mg-eqv/l chlorides – mg/l sulphate – mg/l Fe – mg/l dry particles – mg/l coloration – degree dissolved O2 – mg/l turbidity – mg/l rigidity – mg-eqv/l 7.4.3 7.5 7.6 7.7.7 Description 8.1 8.2 8.3 8.4 8.5 8.6 Value 8. Options Witnessed or un-witnessed test for QCP Special tools Spare parts: - for a commissioning - for a guarantee period Oil supply - first filling Glycol supply - first filling Comments to be included___ to be included___ to be included___ to be included___ to be included___ to be included___ Please, send us the filled-out questionnaire by: E-mail: energy@bpc.ru Fax: +7 (495) 780-31-67