SMCP-250 Arctic wellhead compressor unit Compression & Solutions emission · Energy efficient

advertisement

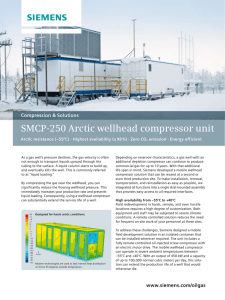

Compression & Solutions SMCP-250 Arctic wellhead compressor unit Arctic resistance (–55°C) · Highest availability (≥ 98 %) · Zero CO2 emission · Energy efficient As a gas well’s pressure declines, the gas velocity is ­often not enough to transport liquids upward through the tubing to the surface. A liquid column starts to build up, and eventually kills the well. This is commonly ­referred to as “liquid loading.” By compressing the gas near the wellhead, you can ­significantly reduce the flowing wellhead pressure. This immediately increases your production rate and prevents liquid loading. Consequently, using a wellhead compressor can substantially extend the service life of a well. Designed for harsh arctic conditions Modern technologies are used to test internal heat distribution at minus 55 degrees outside temperature. Depending on reservoir characteristics, a gas well with an additional depletion compressor can continue to produce commercial gas for up to 10 years. With that additional life span in mind, Siemens developed a mobile wellhead compressor solution that can be reused at a second or even third production site. To make installation, removal, transportation, and reinstallation as easy as possible, we integrated all functions into a single skid-mounted assembly that provides easy access to all required interfaces. High availability from –55°C to +40°C Field redevelopment in harsh, remote, and even hostile locations requires a high degree of customization. Both equipment and staff may be subjected to severe climate conditions. A remote controlled solution reduces the need for frequent on-site work of your personnel at these sites. To address these challenges, Siemens designed a mobile field development solution in an isolated container that can be installed wherever required. The unit includes a fully remote-controlled oil-injected screw compressor with an electric motor drive. The mobile wellhead compressor can operate in severe ambient temperatures b ­ etween –55°C and +40°C. With an output of 450 kW and a capacity of up to 100,000 normal cubic meters per day, this solution can extend the production life of a well that would otherwise die. www.siemens.com/oilgas The unit can also be equipped with an optional XL highefficiency inlet separator that includes a slug catcher and an inlet cooler. A high efficient inlet separator and oil conditioning equipment prevent oil degradation. These systems prohibit oil viscosity drop, accumulation of salts, water contamination, and the buildup of aggressive substances. Proven technology for tough conditions In collaboration with a major Russian gas producer, ­Siemens has developed a compression solution suitable for reliable operation in extremely low ambient temperatures. It features a superior temperature resistance and houses the compressor and controls in two separately conditioned rooms. It also includes an indirect closed cooling system. O ­ ther features include made-to-measure heating, air-conditioning and v­ entilation systems, perfectly adapted to the unit’s heat development while in operation. Customized solutions based on a proven concept Because compressor oil degradation is the most reported cause of failure in unconditioned gas applications, Siemens offers customized solutions to prevent frequent oil change and severe rotor bearing damage. These include: ■■ Highly efficient inlet separators ■■ Two-stage inlet separator systems ■■ Slug catchers ■■ Inlet gas coolers ■■ Special oil type selection ■■ Alternative oil temperatures ■■ Dedicated bypass oil conditioning systems ■■ Independent bearing oil system In addition, our oil-flooded screw compression solutions consist of standard class A components and equipment, and include automation and remote monitoring to allow for unmanned operation. The compressor’s high efficient oil-separator helps ensure low oil carry-over. Specifications for Siemens Mobile Wellhead Compressor Unit SMCP-250 arctic* Rated power 450 kW Capacity (inlet 2 bar (a)) 100,000 nm3/d Inlet pressure ≥ 1 bar (a) Discharge pressure ≤ 12 bar (a) Ambient temperature –55°C to +40°C Compressor type Oil-injected screw compressor Driver type Electrical Capacity control Slide valve / Variable speed (option) Cooling Air-cooled closed cooling water system Control and operation Local panel on skid / Telecontrol (option) Applied standards ASME, API 619, 97 / 23 / EC Pressure Equipment Directive, GOST-R, R ­ ostekhnadzor Single lift unit Yes Dimensions compressor unit (l x w x h) 12.0 x 2.6 x 3.0 m Dimensions cooling unit (l x w x h) 7.2 x 2.8 x 2.8 m Weight compressor unit 35 tons Weight cooling unit 7 tons * Units are designed for road transport. Specifications may vary per specific design. The Siemens Wellhead Compressor Family Discharge pressure bar (a) SMCP-250: 25-100 SMCP-300: 40-200 20 SMCP-500: 60-300 15 10 5 Flow (1000 nm3/d) 50 100 150 200 250 300 Siemens Netherlands Prinses Beatrixlaan 800 2595 BN Den Haag For more information contact our Centre of Competence for Field Redevelopment: Siemens Netherlands Energy, Oil & Gas, Compression and Solutions E-mail:oilgas.nl@siemens.com. Phone: +31 703 333 333 Oil & Gas Division Order No. E50001-G440-A181-X-4A00 | Printed in Germany | Dispo 21618 | c4bs No. 7807 | TH 104-120506 | BR | 000000 | DB | 06122.0 © 06.2012, Siemens AG www.siemens.com/oil-gas