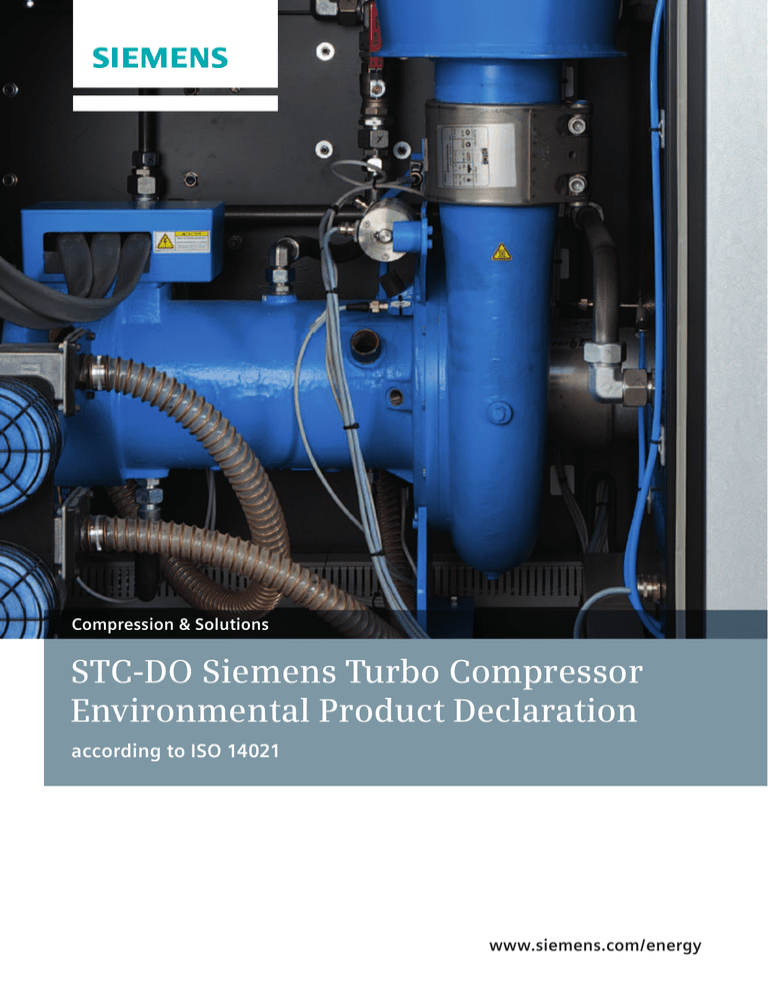

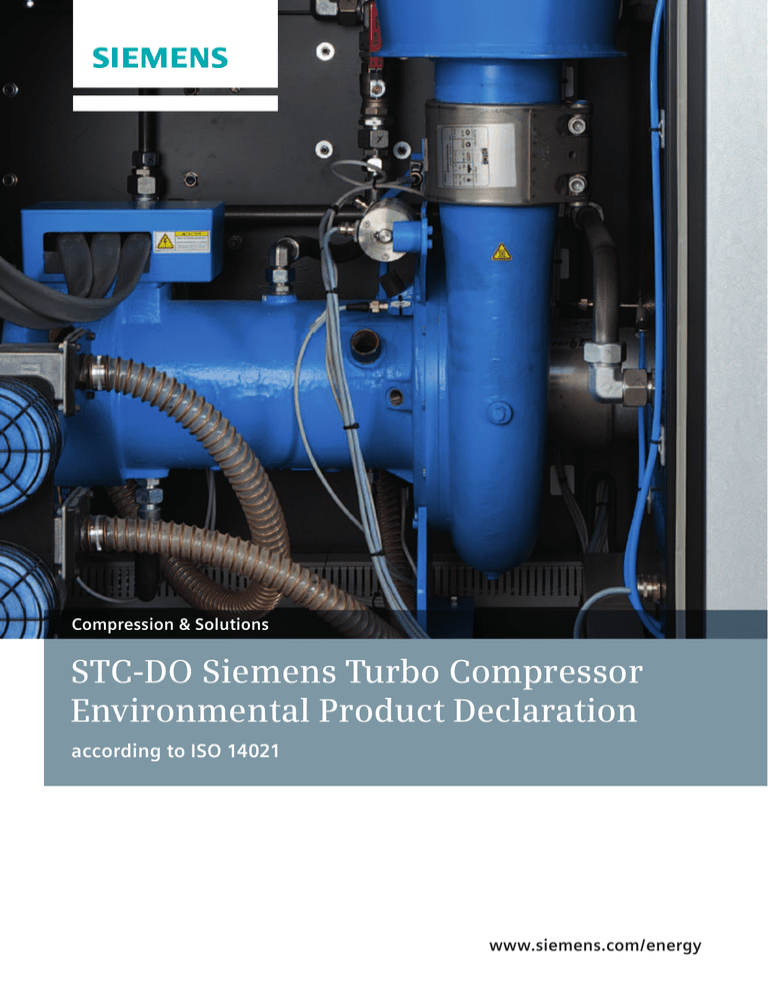

Compression & Solutions

STC-DO Siemens Turbo Compressor

Environmental Product Declaration

according to ISO 14021

www.siemens.com / energy

Sustainability as opportunity

Sustainability is the basis for how we do business

Our goal is to create value for the long term by treating

people and the environment in a responsible manner.

Innovative products and solutions are the foundation

for our success

They help our customers to achieve their business goals

while meeting global challenges such as urbanization,

demographic change, climate change and resource

scarcity.

We walk the talk

We pursue ambitious goals with regard to resource efficiency and environmental protection; we see our employees as our most valuable asset and develop them for the

long term; we value a corporate culture with a strong

emphasis on integrity; and we promote education, social

issues, arts and culture wherever we operate.

Siemens aims to set the highest standards for Environmental Protection. We urge our business partners to share

this ambition. We cooperate with both customers and

­suppliers in an honest and open dialog in order to drive

forward a joint effort to attain continuous improvement.

The main objective of our environmental work is to

­prevent pollution and continually to reduce the environmental impact from our activities in order to protect the

environment for future generations.

To meet these objectives, we will maintain and further

develop a culture in which reducing the environmental

impact of the product life-cycle is an integral part of our

daily work practice. Our integrated management system

for environment, health and safety, ISO 9001, 14001

and OHSAS 18001, is implemented worldwide within

the Siemens Energy Sector.

3

Environmental Technology

Increasing worldwide water consumption combined with

the effects of climate change affecting water scarcity in

regions throughout the world mean that the treatment

and reuse of water is becoming ever more important.

­Siemens offers an extensive range of aeration and water

treatment solutions which not only address the need to

provide cost effective, reliable water solutions, but which

also improve the efficient use of one of the worlds most

important resources.

Product stewardship: The Siemens standard SN 36350

Environmental compatibility is a cornerstone of product

design at Siemens. In 1994, we published an in-house

standard, SN 36350, to advance environmentally friendly

product design throughout the company. The standard

has since been expanded to provide product development

engineers with a comprehensive toolbox.

Siemens’ SN 36350 defines standards for

environmentally compatible product and system design

handling of critical substances

packaging

declaration of substances in products

environmental product declarations.

These requirements and regulations are accompanied by a

guideline giving examples of how to implement the standard’s requirements; a semi-quantitative tool for evaluating a product’s environmental footprint is also available.

The standard describes how to address the needs of

­environmentally compatible product and system design

in management systems.

Environmental Product Declaration

The data in this Environmental Product Declaration (EPD)

are related to one STC-DO (5SF-A), a compressor for waste

water treatment. The environmental impact is given by

the specific material footprint and by the global warming

potential (GWP) related to the product. The GWP has been

evaluated within a full scale Life Cycle Assessment study

according to ISO 14040.

4

Single stage direct drive centrifugal core compressor

with Synchronous permanent magnet motor and

­airfoil bearings (STC-DO 5SF-A)

Product description

Material allocation

The STC-DO (5SF-A) combines a 200kW compressor core

unit with the entire package of instrumentation and support equipment as shown on in the picture. The aeration

blower is suitable for waste water treatment plants, for

fermentation applications and other biological processes.

This compact blower uses a centrifugal compressor stage

with a pressure ratio up to 1.1 bar (at 20°C, 80% RH and

barometric pressure of 1,013 bar). The variable speed

drive and adjustable diffuser vanes enable a high efficiency over a large operating range (Dual PointTM ­Control).

Air foil bearings replace the traditional ball-or journal

bearings.

The STC-DO (5SF-A) consists to over 80 percent of ferrous

and non-ferrous metals, predominantly un-alloyed steel.

The diagramm shows the corresponding material

allocation.

3%

32 3%

3%

2% 2%

2%

9%

44%

10%

22%

n Unalloy steel

n Cast iron

n Insulation material

n Aluminium

n Low alloy steel

n Copper

n High alloy steel

n Plastics

n Electronics

n Others

5

Key Environmental Performance Indicators

Siemens uses standard life-cycle software for the evaluation of the environmental impact of all product life-cycle

stages. All results are verified by internal reviews.

Global Warming Potential

Global warming is the rising of the global temperature

due to emissions of greenhouse gases such as carbon

dioxide and methane. The GWP is evaluated in CO2

equivalents.

The GWP of the STC-DO (5SF-A) prior to the operational

phase is shown in the diagram.

Global Warming Potential

60

58%

50

37%

40

30

20

10

5%

As aeration is an energy consuming process the operational phase dominates the life cycle. Related to the whole

life cycle the operational phase would be responsible for

up to 99% of the GWP.

It is also for that reason that Siemens sets a high value

on the development of very high efficient products and

solutions.

The STC-DO (5SF-A) meets all these environmental and

technological challenges.

Environmental benefit

Traditional geared centrifugal compressors driven by

an conventional electric motor have been used for aeration in waste water treatment plants. These units use

lubrication oil for the gears and bearings. For the STC-DO

(5SF-A) the gear box was replaced with a direct drive

high speed e

­ lectric motor running in air bearings. The

application of airfoil bearings results in exceptionally long

life with minimal maintanance since no lubricating oil is

required.

Compared to a similar compressor with conventional bearing technology the STC-DO (5SF-A) avoids the consumption of over 2100l* lubrication oil over its lifetime.

0

Material

Manufacturing

Testing

“End of life” – Recycling reduces the environmental impact of

the product and gives a positive contribution to the overall GWP

of the product (not shown).

6

*based on base load operation and 15 years assumed lifetime

Description of the

life-cycle stages

An important product focus for Siemens is to minimize

the environmental impacts from resource extraction

through to ultimate disposal. At every stage, Siemens

has developed trendsetting solutions in accordance with

sustainable life cycle thinking.

Materials

The life-cycle stage “Materials” includes the material inventory which involves the extraction of

natural resources, transport to the processing

sites and the production of raw materials

All product materials have been chosen with

regard to minimizing the environmental impact.

The STC-DO (5SF-A) consists mainly of ferrous

and non-ferrous metals, which ensures a high

degree of recyclability.

Manufacturing & Testing

The “Manufacturing” section covers all production

processes up to the assembly of the finished product at the manufacturing site. The essential data

like energy, water and gas consumption are based

on the annual manufacturing data of the site.

The “Manufacturing” section also includes the

transportation efforts, mainly per sea, to the customer site. For this LCA a customer site in the US

was assumed.

The environmental impact is covered by the

“Testing” section.

Before leaving the factory each compressor is

mechanically and functionally tested in our

advanced test rig in accordance with our Standard Shop Test Specification.

Operation

The operational phase covers all environmental

impacts of the described product system during

its operation phase. For this LCA the environmental impact was evaluated on the basis of one STCDO (5SF-A) running within a waste water treatment application with an assumed operating

time of about 15 years. However, the STC-DO

(5SF-A) can also be used within other

applications.

By using air bearings oil as a lubricant is not

needed.

End of life

The end-of-life scenario includes the disassembly,

recycling and thermal treatment of all recyclable

materials and also the disposal of all other

materials.

Recycling reduces significantly the consumption

of primary materials. A high degree of recyclability is given due to the high amount of steel for

the STC-DO (5SF-A). In the case of steel the recycling rates are nearly 100%.

7

Published by and copyright © 2012:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Oil & Gas Division

Wolfgang-Reuter-Platz

47053 Duisburg

For more information, contact our

­Customer Support Center.

Phone: +49 180/524 70 00

Fax: +49 180/524 24 71

(Charges depending on provider)

E-mail: support.energy@Siemens.com

www.siemens.com/energy

Oil & Gas Division

Order No. E50001-E420-T129-X-4A00

Printed in Germany

Dispo 34806, bdk 120134, WS 0512

Printed on paper treated with

­chlorine-free bleach.

All rights reserved.

Trademarks mentioned in this

document are the property of

Siemens AG, its affiliates, or their

respective owners.

Subject to change without prior

notice. The information in this

document contains general

descriptions of the technical

options available, which may not

apply in all cases. The required

technical options should therefore

be specified in the contract.