Power is money –

Cut energy costs by up to 50 %

Electrical Solutions

Instrumentation, Controls & Electrical

Your Benefits

■ Lower energy costs

■ Reduced environmental

burden

■ Higher returns thanks to

higher capacity and lower

CO2 emissions

■ Short payback period

SPPA-E3000 Drive Modernization

is how to optimize the energy efficiency of drive

systems with frequency converters and energysaving motors.

2. Energy-efficiency analysis

Suitable drive systems are identified and the

energy-cost-savings potential is precisely quantified. Based on the actual on-site conditions,

we draw up a concrete optimization concept.

The Task

More than 97 % of the entire life-cycle costs

of drive systems are attributable to the costs

of the energy needed to operate them. Over

two thirds of the plant's auxiliary power

demand comes from electrical drive systems.

About 30 % of the drives for say pumps and fans

could be run more efficiently. This considerable

savings potential is waiting to be tapped.

3. Technical implementation

■ Planning and engineering

■ Replacement of obsolete

and inefficient hardware

■ Installation of high-quality frequency

converters and high-efficiency energy-saving

motors

■ Commissioning and parameterization

of the components

■ Optimization of operating times

and operating points

■ Final measurements, calculation

of power consumption

■ Best-in-class project management (VGB

Quality Award)

Our Solution

comprises assessing the potential savings,

analyzing suitable measures and implementing

them to modernize the drive systems. The focus

is first set on those drives that promise a shortterm payback for the cost of the upgrade.

We focus primarily on

■ electronic speed control instead

of mechanical throttling

■ modernization of installed

frequency converters

■ use of energy-saving motors

■ recovery of decelerating energy

during breaking

The solution can be linked up to the existing

instrumentation and control system for operator

control and monitoring.

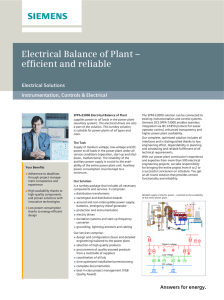

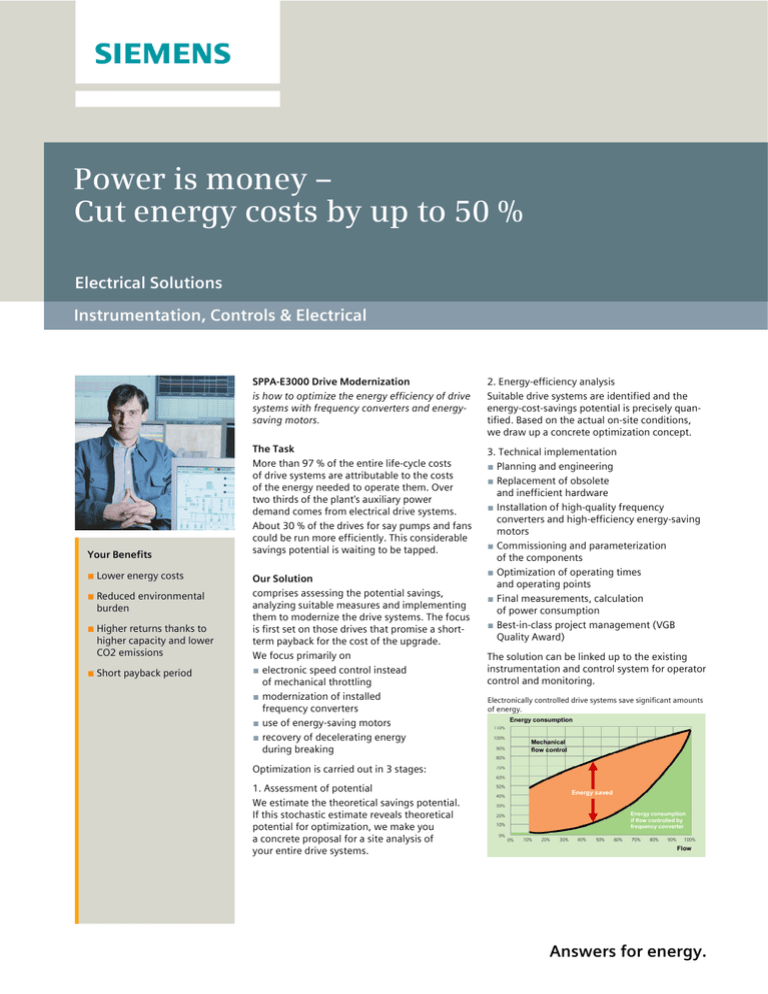

Electronically controlled drive systems save significant amounts

of energy.

Energy consumption

Mechanical

flow control

Optimization is carried out in 3 stages:

1. Assessment of potential

We estimate the theoretical savings potential.

If this stochastic estimate reveals theoretical

potential for optimization, we make you

a concrete proposal for a site analysis of

your entire drive systems.

Energy saved

Energy consumption

if flow controlled by

frequency converter

Flow

Answers for energy.

Published by and copyright © 2012:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-e3000.energy@siemens.com

www.siemens.com/energy/sppa-e3000

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

E306_FS00_DrMod_e_V2-0

Order No. E50001-G230-A241-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.