Increased Availability

for GE Frame Gas Turbines

Turbine Controls

Instrumentation, Controls & Electrical

SPPA-R3000 Turbine Controls

is the perfect modernization solution with

comprehensive automation functions for

gas and steam turbines from any vendor.

Your Benefits

■ Increased availability and

lifetime

■ Increased operational

reliability

■ Increased flexibility

■ Reduced maintenance costs

The Task

In addition to expensive spare parts

warehousing, an increasing failure probability

affecting the mechanical and electrical

components utilized to control and protect

GE Frame gas turbines results in decreasing

availability and deteriorating operational

reliability.

The main turbine and generator components

still retain a high residual lifetime. The old

control and protection systems are no longer

up to the task of meeting today's requirements

for cost-effective operation of the turbosets.

Our Solution

SPPA-R3000 offers concepts that are adapted to

the specific requirements of GE gas turbines of

types Frame 5, Frame 6, Frame 7, and Frame 9

and have proven their worth over and over in

operation.

In addition to the control system, the

modernization solution can also include

vibration monitoring and analysis, electrical

engineering, modernization of the hydraulic

system, and field instrumentation.

The basis is the globally leading SPPA-T3000

control system that forms the platform for

automation, control and protection. It is

employed for turbines, auxiliary systems

and the main control system, and permits

seamless integration of all functional areas

of the plant. Thanks to its scalability, it can be

used not only as a stand-alone turbine solution

but also for modernization of the entire plant

with a uniform operating and engineering

environment.

Our service portfolio comprises everything

from feasibility studies to the mapping of

basic functionalities for GE gas turbines,

fail-safe protection with SIL3 certification,

installation/commissioning, and complete

documentation.

Modernization can help to eliminate systembased failures of the legacy system as well as

performance losses that were previously caused

by aging effects on the field and control

devices.

Moreover, the start-up process is optimized

as requested by the customer, which can reduce

the start-up time (from standstill to full-load

operation) down to one third.

The incorporation of turboset auxiliary systems

such as the air/oil cooler or the H2 system and

integration into the unit-level control system

for operation and monitoring permit more

efficient operational management.

The replacement of failure-prone capillary

actuators with advanced electrical servo

actuators and software-based closed-loop

control algorithms result in improved control

quality and availability.

The entire modernization, which includes

replacement of the GE systems with Siemens

technology, is completed in the shortest

possible time, for example during a planned

turbine overhaul.

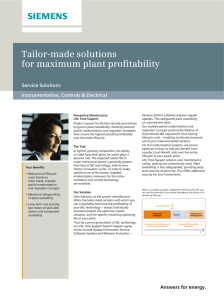

SPPA-R3000 increases the availability of GE gas turbines

– e. g. in Gresik Power Station, Indonesia.

Answers for energy.

The solution can include:

Control system (open-loop

control, closed-loop control,

protection)

Vibration monitoring and

analysis

Electrical engineering (excitation

system, synchronization, unit

protection facilities)

Hydraulic modernization

Field instrumentation

Our service portfolio:

Execution of a feasibility study

Conceptual design –

technological outlining

of the task definition

Functional extension to increase

cost-efficiency, e.g. test functions

to reduce maintenance effort

Customized adaptations of the

solution, e.g. modification of the

operating mode

Fail-safe protection with

SIL3 certification

Installation/commissioning with

optimized timing

Before/after tests (fingerprints)

Complete documentation

Mapping of the basic

functionalities for GE gas turbines

Studies

and

Consulting

Offer

Test Run

‘before’ Mod., Engineering,

Tests ,

Planning,

Realization Manufacturing

Installation

Commissioning

Test Run

‘after’

Mod.

Training

After-Sales

Service

Quality Management

Our comprehensive service portfolio ranges from studies and consulting to after-sales service and is notable for its first-rate quality management.

Published by and copyright © 2012:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-r3000.energy@siemens.com

www.siemens.com/energy/sppar3000

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

R30GT_FS_GE-Frame-Mod_e_V2-0

Order No. E50001-G230-A305-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.