Published by and copyright © 2008:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, contact our

Customer Support Center.

Phone: +49 180/524 70 00

Fax:

+49 180/524 24 71

(Charges depending on provider)

e-mail: support.energy@siemens.com

Energy Service Division

Order No. E50001-G5100-A100-V1-4A00

Printed in Germany

Dispo 05400, c4bs No. 1386 P WS 10082.

All rights reserved.

Subject to change without prior notice.

Printed on paper treated with chlorine-free bleach.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or their

respective owners.

The information in this document contains general descriptions of

the technical options available, which

may not apply in all cases. The required technical

options should therefore be specified in the contract.

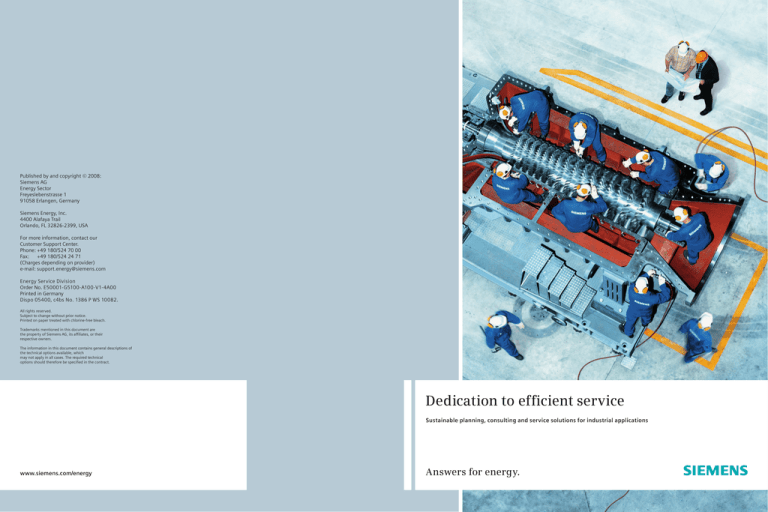

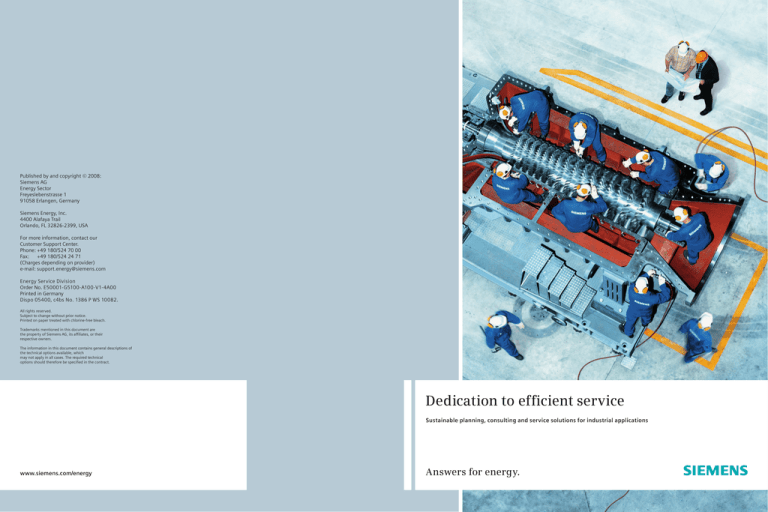

Dedication to efficient service

Sustainable planning, consulting and service solutions for industrial applications

www.siemens.com/energy

Answers for energy.

Services to support your

plant performance and profit

Training & Consulting

Our range of training programs support your

plant’s full life cycle. They include on-the-job

training, classsroom-based training and in-plant

training on our stimulators or at our training

facilities under realistic conditions.

Implementing

Project management is our specialty. Our experience

gained in hundreds of successful projects enables

us to plan each implementation step exactly.

And we never leave the customer until everything

is up and running properly.

Operating

You can either run your plant yourself - or let us run

it for you. We offer operating services to match your

strategic business needs. You define the level of

everyday support. We even provide the plant staff

and fully operate the plant. We run many plants

around the world.

Maintaining

Regular inspections help recognize conditions which

require maintenance or repairs at an early stage.

Our services, such as non-destructive examination

techniques, are developed for quick analysis

and enable intelligent decision making that can

help to cut your costs significantly.

Our performance helps to improve yours

The driving force behind Siemens Energy Service division is a dedication to speed of response and customer

intimacy. This is because the goal is to deliver sophisticated energy services fast. Services that are designed

to fit your plant‘s performance needs and your business goals perfectly.

Our global network plays a central role in helping us meet this commitment. We are present in 161 countries

worldwide and our six Product Lead Centers and 18 Service Shops offer the world-class logistics to deliver fast

and effective results.

We do not just offer rapid response and proximity, we also offer our customers personal closeness.

We want to really get to know our customers and their personal and technical needs. This makes it easier for us

to understand problems, find solutions and, above all, deliver help and support more efficiently.

Repairing

Changing and repairing components is a routine job.

Our goal is to help you stop operating issues

from becoming outages. We are helped by incidents

diagnostic systems - and our experience.

All our efforts focus on keeping your plant online

or putting it back on the grid as quickly as possible.

Modernizing

There are various ways of maximizing plant

efficiency. For instance, you can increase output

without using more fuel and you can turn an oldertype plant into a modern one. Our modernization

solutions are known for their effectiveness in terms

of business success and environmental impact.

Extending Lifetime

When plants reach their designed lives, safety

and availability decrease. Our metallurgical,

integrity and fracture mechanics analyses reveal

the real state of your plant and enable adequate

lifetime extension measures - important assets

in the deregulated electricity market.

Choose the service that is right for your business from our comprehensive portfolio.

2

3

Our goal is to overcome market

challenges every day

Engineering excellence with unique market insight

Service for Compressors

The energy market is becoming increasingly

complex and challenging. Costs are rising

and governments are tightening legislation,

creating economic and political obstacles

to achieving and maintaining plant profitability. At the same time, demand for energy

is at its highest level ever, increasing the

pressure for maximum output.

Service for Generators

We at Siemens understand that you need

to get the most out of your plant every day.

We are dedicated to removing unscheduled

downtime and keeping scheduled

downtime to a minimum. Our certified

processes are designed to ensure that

each plant component, from the smallest

valve to a complete turbine, functions at

maximum capacity. In addition, our

worldclass logistics help you react to and

deal with today’s challenges faster.

Helping you plan for tomorrow‘s market is

another of our core service commitments.

We focus on long-term operational flexibility,

putting you and your plant in the perfect

position to adapt to future industry developments, take advantage of new energy

opportunities and respond to potential

challenges.

Service for Steam Turbines

Service for Medium Gas Turbines (MGT)

Service for Small Gas Turbines (SGT)

4

5

Nothing is faster

than already being there

Fast service for safer planning

In today‘s fast-moving world, it is even

more important to have a partner you can

rely on to deliver support and assistance

immediately. Whether a valve has to be

replaced or a turbine has broken down,

our global network has the resources to

respond fast and effectively, anywhere in

the world. We are present in 161 countries

worldwide and have 18 Service Shops

around the globe, all manned by local

experts who are dedicated to getting

your plant back on the grid as quickly as

possible and preventing such incidents

from happening again.

6

Siemens’ assistance is only a phone

call away. Around-the-clock emergency telephone service is manned

by a team of operational support

specialists. They are ready to provide

assistance in the running of

your plant.

It is not just geographical proximity that

enables us to respond quickly. Our dedication

to establishing close customer relationships

helps us understand and anticipate your

plant‘s operational and equipment needs

inside out. Which, in turn, enables us to

effectively implement certified processes

designed to improve quality and streamline

functionality, thus saving you valuable time.

7

To know is to understand

Closer to your business

No two plants are the same. Each has

specific technical, operational, financial

and environmental needs. Which is why

we at Siemens Energy Service encourage

you to share your values, aims and

individual requirements with us, enabling

us to understand what makes your plant

different. This gives us access to unique

insights, enabling us to spot weaknesses,

identify hidden potential and enhance

both short and long-term performance.

ding

ten e

Ex fetim

Li

Trai

Con ning

su &

lti

n

lementing

Imp

Modern

izin

g

g

ri n

in

ai

g

Rep

An added benefit of building close

working relationships is that you are

assigned a dedicated service team to

work directly with you. This gives you

a single point of contact, be it a replacement parts professional to advise you on

delivery and installation or the project

manager responsible for running your

entire plant.

at

g

Ma

in t ainin g

Op

er

Siemens Energy Service offers you

a wide range of opportunities.

Whether you need an immediate

part replacement or are planning

a long-term operation such as the

performance enhancement of a turbine. We can also offer you several

maintenance contract options. You

decide when and how often to take

advantage of our support. This is

possible throughout a product‘s entire

lifecycle or for certain phases.

We can offer you the exact service

to fit your requirements perfectly.

Service program for client A.

Service program for client B.

8

9

Turning good into better

Performance Enhancement Programs

Improving your plant‘s performance

does not have to be costly or time consuming. Just a small change can make a

huge difference: it is all about choosing

the right one. We at Siemens are committed

to finding cost-effective and efficient

ways to improve your processes, maximize

your output and lower your environmental

impact.

We plan and undertake extensive plant

inspections and operational analysis to

identify enhancement potential.

Our performance enhancement programs

include introducing low maintenance

components, upgrading hardware,

optimizing workflows or modernizing

computer interfaces. In addition, finding

ways to reduce emissions and improve

performance is one of our main service

priorities.

10

In a performance-based market

structure, where plants are managed

as profit centers, it is necessary to

strategically improve efficiency,

optimize capacity, minimize costs

and maintain high reliability in

order to be competitive.

Effective and accurate maintenance planning

is also crucial to getting the most out of a

plant. Our in-depth knowledge of your

equipment allows us to anticipate repair

works and plan timely intervention,

reducing unnecessary downtime. We also

closely monitor equipment and machinery,

enabling us to identify the best time to

upgrade them to meet changing market

developments. By simply planning ahead,

we can help make an aging plant match

the competitive performance of a new

one for years to come.

11

Identifying faults before

they become failures

Corrective & Performance Maintenance

One of our major service goals is to keep

your downtime and subsequent loss of

productivity to a minimum. Rather than

wait for complications to occur – from

the tiniest defects to potential worstcase shut down scenarios – we act preemptively to prevent them happening.

Once our advanced remote monitoring

and diagnostic services have identified

the issue, our team of specialists are then

able to plan and advise on necessary

action in advance.

Some repairs and service work are

unavoidable. But we have the processes

and expertise to ensure that necessary

repairs do not slow you down. Working

closely with you, we anticipate potential

maintenance requirement and plan time

and cost effective ways to implement

them. Whether it is replacing a defective

valve, unblocking a pipe or overhauling

a turbine, we are the partner you can rely

on for fast, effective and comprehensive

maintenance that will not affect your

productivity.

Siemens Energy Service assembles a

regional team of experts that works

directly with you to determine your

needs. By utilizing advanced project

management, supervisory and scheduling techniques to coordinate all

required activities, we are able to

oversee the successful completion

of turbine-generator maintenance

projects.

Waiting for replacement parts can also cause

unnecessary delays. Our comprehensive

replacement parts service keeps up the

levels of your stocks, guaranteeing fast

delivery and removing the need to tie up

capital in in-house storage.

We will even assign you a parts professional to help track your parts and oversee the process. It is all about having a

service provider who can get the right

part to the right place at the right time.

12

13

Finding the right options for you

from a world of choices

Service Programs

By opting for a Siemens service program,

you are choosing the reassurance of a set

timeframe and budget. You also have

the peace of mind of assigned personal

points of contact as well as agreed

planning procedures and maintenance

routines.

Regardless of whether your service

requirements are big or small, Siemens

can proactively boost your plant‘s longterm performance with a variety of

customizable options to fit your individual

needs, both technical and financial.

For example, our long-term gas turbine

program has proven particularly effective

in helping plants around the world effectively

manage and reduce downtime.

14

We are able to respond rapidly with

replacement parts. This is because

we stock 23,000 styles and over

4 million parts in the central parts

warehouse, ready for same-day

shipment 24 hours a day, 7 days

a week.

15

Giving you the power

of knowledge

Training & Consulting

We at Siemens understand that knowledge is one of the most important tools

in the industry and that it can give you

a clear competitive advantange. Welltrained staff who can face any challenge

are vital to operating your plant efficiently and productively.

That is why the Siemens Power Academy

offers a wide range of customized training

programs for plant management, operation

and maintenance. Training is available

on site, online or at our state-of-the-art

training facilities including real-life simulators for worst case scenarios. Our wide

range of training courses caters for every

stage in a plant‘s lifecycle, covering in-depth

and essential equipment and systems

knowledge, preventing or carrying out

repairs, as well as health and safety.

16

No amount of theory can replace

learning by doing. Which is why we

focus on both, classroom and handson-training to provide more learning

opportunities.

We also offer a comprehensive range of

tailor-made consulting services, such as

advice on building new plants, extending

your plant‘s lifecycle, cost-effective operation, safety and environmental issues and

much more. Siemens is the partner to

consult if you want to take your plant

forward.

17

References

Creating success stories

by working together

At Siemens, we have a long tradition of

building successful client relationships.

Based on mutual understanding and

respect, these relationships play a key

role in helping us meet our clients‘ specific

needs and individual requirements.

This in-depth knowledge, combined with

our unparalleled expertise, facilitates

solutions to even the most complex tasks

such as regenerating aging turbines.

We also make it a priority to deliver these

solutions with minimum downtime.

18

The three reference projects are perfect

examples of our operational flexibility

and goal-oriented processes.

Customer

Customer

Customer

Morgan Stanley

LyondellBasell Industries (former BP Plant),

Münchsmünster, Germany

INEOS Köln (also known as EC ErdölChemie

or BP Köln and Innovene)

Background

Background

Background

When Morgen Stanley took over the Berkelcentrale cogenerating station in Holland,

they were looking for a reliable and flexible

partner with the engineering solutions to

meet their requirements.

LyondellBasell Industries needed to upgrade

an aging steam turbine to extend its operating

life and improve efficiency.

INEOS Köln ordered a large-scale shutdown of the

Kracker 5 plant. This required meticulous planning

to keep downtime to a minimum while extensive

work took place such as replacing parts and

carrying out large and small-scale overhauls.

Product

Product

Product

Gas Turbine

SGT-600 a brand new gas generator (GG)

combined with the existing power turbine

(PT).

Steam Turbine

3 trains: a footprint turbine with 2 footprint

compressors behind it, an ethylene train and

a propylene train.

Compressor and Steam Turbine.

Scope

Scope

Scope

Refurbishment/upgrade of an older unit with

a high number of start-stop cycles to meet

the new operating profile. Upgrade of the

combined heat and power plant for maximum operating flexibility to maximize revenues from power sales in an unpredictable

wholesale market.

Siemens had stored all original data and was able

to produce a footprint for the machines.

With this footprint the downtime could be kept

to the bare minimum. In this case, footprints

were created for two new Steam Turbines and

one raw gas compressor train.

There were two years of preparation work with

a team of ten for the preparation phase.

The cooperation of different Product Lead

Centers and 45 people in two shifts working

together at INEOS Köln in the overhaul phase

was needed to replace a gas turbine with a body

turbine and to do small-scale and long-scale

overhauls for ten different machines.

Result

Result

Result

The operating life of the two gas turbines

was dramatically extended.

The expertise to create footprints for the existing

machines facilitated the successful completion

of the project.

Completed with a minimum downtime

of only 6 weeks according to schedule.

19