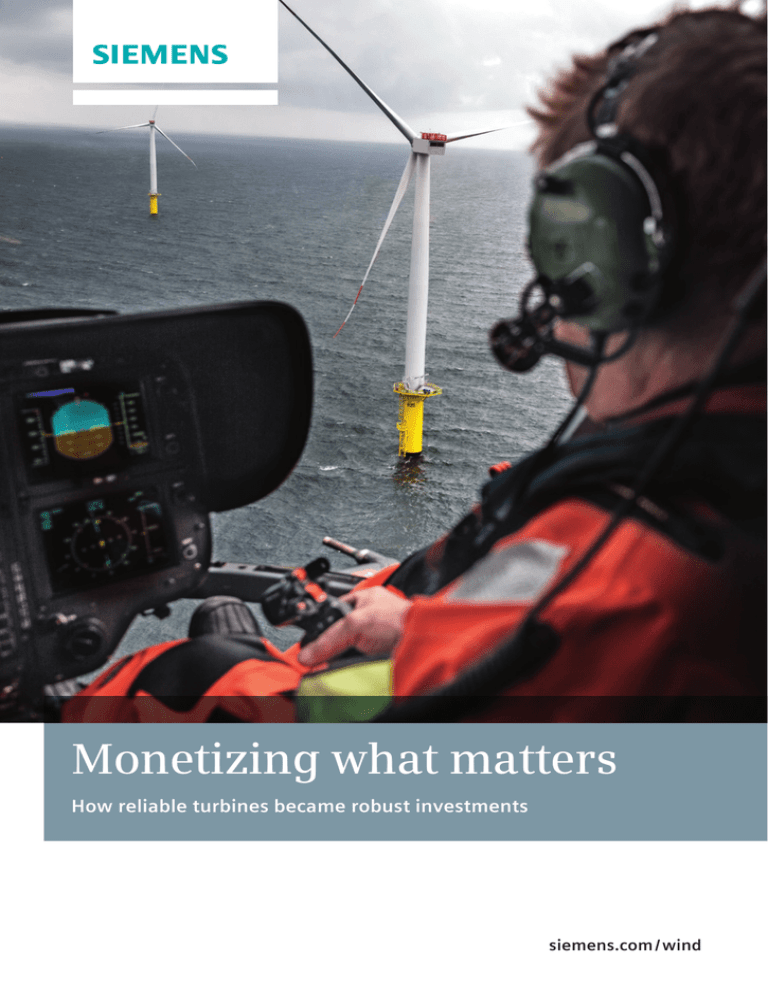

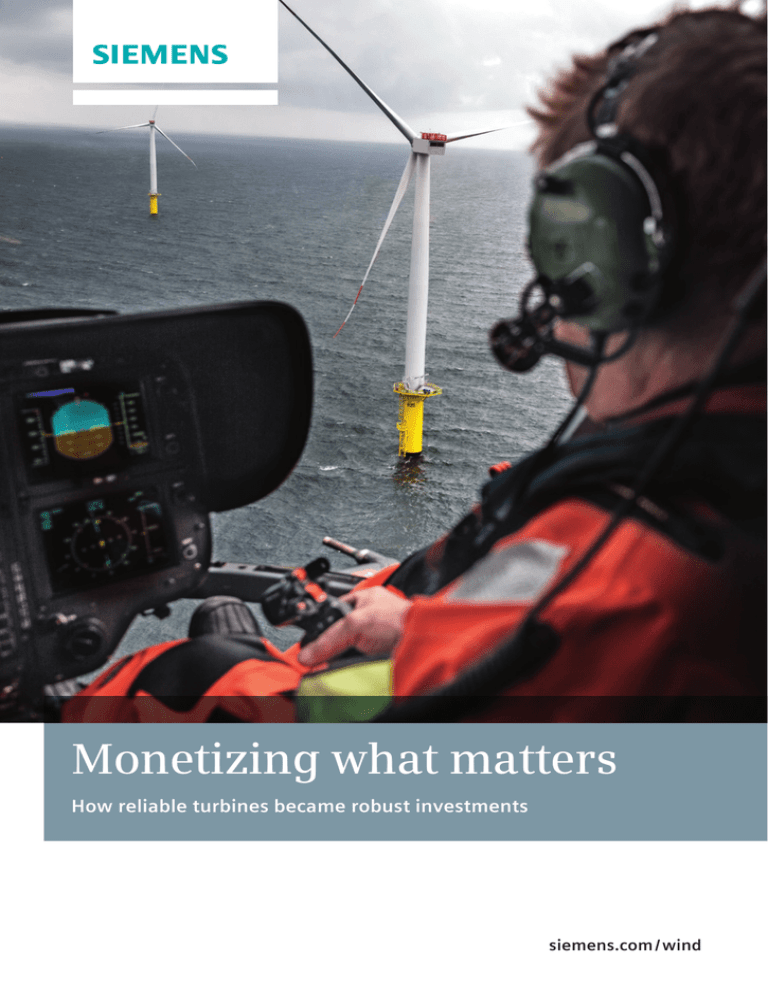

Monetizing what matters

How reliable turbines became robust investments

siemens.com / wind

Offshore wind power

comes of age

From reliable turbines...

...to robust investments

In the quarter-century since Siemens installed the world’s

first offshore wind power plant off Denmark, the capacity

of offshore turbines has increased more than tenfold.

Offshore wind is now established as a viable energy

source and a reliable way to achieve emissions targets.

Once financed almost exclusively by utilities providers,

offshore is now acknowledged by bankers as a dependable

asset. For many investors, the question is no longer

whether to invest in offshore. Rather which offshore

provider will make the most reliable partner long term.

Having installed the first-ever offshore wind turbines at

Vindeby in 1991, Siemens was the first company to face –

and overcome – the substantial challenge of maintaining

and improving unproven offshore technologies. By taking

the lead in maturing offshore wind power products and

services, Siemens gradually acquired an unparalleled

wealth of experience and expertise – to the benefit of its

investing partners today.

Siemens’ experience gave confidence to commit

resources to the offshore industry long term. And taught

the company how best to allocate those resources to

deliver maximum reliability. For Siemens’ partners, this

combi­nation of experience, reliability, and long-term

commitment helps make Siemens Wind Power Offshore

Techno­logy a robust investment.

“A gram of experience is worth

a ton of theory.” U.K. Prime Minister Robert Gascoyne-Cecil

3

Excellence at every stage

Turbine Reliability

Despite the difference in scale between the first, 450 kW offshore wind turbines

that Siemens installed in 1991 and the multi-megawatt models currently deployed

offshore, many offshore industry standards can be traced back to that first site at

Vindeby.

Indeed, Siemens engineers used the experience gained from this project to further

improve design, sourcing, and manufacturing. A three-stage manufacturing cycle

evolved that still continues from platform to platform. Together with a rigorous

testing regime and product platform strategy, this cycle lays the groundwork for

product maturity and reliability.

Stage 1: Reliable design

Siemens builds reliability into every wind turbine platform by reusing proven components, design principles, and technologies from one product generation to the next.

The more components from the previous generation, the more predictable performance and service with the new platform.

Stage 2: Reliable sourcing

Successful sourcing requires intensive monitoring of the components provided

by suppliers and subsuppliers. The exhaustive efforts of Siemens’ quality-control

teams is characterized by a dedication toward always complying to Siemens’

quality standards.

Stage 3: Reliable assembly

Drawing inspiration from carmakers, in 2010 Siemens took the first step toward

industrializing wind turbine manufacturing, with the introduction of moving-line

assembly. This ensures higher and more consistent quality standards and enables

more efficient use of the company’s manufacturing facilities.

G2

Platform

Design

Sourcing

Assembly

4

G4

Platform

D3

Platform

D7

Platform

Every Siemens platform builds on the strengths of its predecessor,

from the G2 introduced in 1999 to the current D7. Platforms with

a ‘D’ in the name use direct drive technology. ‘G’ stands for geared.

...far beyond industry

standards

Pre-prototype testing

Uncompromising

testing...

Whereas certification of structural safety

and electrical systems is a legal requirement, validating the robustness of other

systems and components effectively

remains optional. To help safeguard our

partners’ investments, Siemens also rigorously tests materials, major components,

and modules prior to prototype testing.

Prototype testing

Higher and more consistent offshore

wind speeds increase returns for investors

and operators alike, but they also present

significant challenges. The sheer scale of

offshore maintenance operations makes

investment safeguards such as thorough

testing all the more crucial for offshore

wind turbines.

Pioneering procedures

Exceeding expectations

In response to the increasing importance

of offshore wind power and the challen­

ges of the offshore environment, Siemens

introduced a structured approach to testing. Blades, bearings, gearbox, and other

major components were pushed to their

limits and the first G4 turbine – the

SWT-3.6-107 – was subjected to more

than 200 separate, highly accelerated

lifetime tests. These procedures have

been repeated for every new turbine

design since.

As the first company to introduce an allembracing test program for offshore

wind turbines, Siemens offers its partners

un­rivaled experience of test procedures.

To deliver the consistent quality Siemens

customers expect, these procedures have

been developed even further than most

requirements specified by the industry’s

certifying bodies.

6

2004 saw two milestone achievements

for the offshore sector: the launch of the

first dedicated offshore wind turbine

platform (the Siemens G4) and the introduction of the first fully fledged offshore

test program. Siemens’ partners were the

exclusive beneficiaries of both.

Prototype turbines provide valuable operational experience. They help to verify

initial calculations from the design stage

and are essential to further research and

development. Prototype test results feed

into the verification and implementation

of service programs as well as solutions

for new turbine designs.

Material, component, and module testing

takes place at Siemens’ dedicated test sites

in Aalborg or Brande, both in Denmark.

Together, they form the largest windturbine testing facility in the world.

Turbine Reliability

Turbine testing comprises three main

stages: structural, mechanical, and electrical testing. Before the first prototype

turbine can be erected in the field, a

certification authority must verify its

overall structural capacity.

1

2

3

4

Tested at every level

Step

4

Step

3

Step

2

Step

1

Prototype test

Module test

Component test

Material test

7

2015

Gwynt y Môr

160 turbines

3,600 kW

From world’s first to

world-class

2014

West of Duddon Sands

108 turbines

3,600 kW

2012

London Array Limited

175 turbines

3,600 kW

2003

Nysted

72 turbines

2,300 kW

1991

Vindeby

11 turbines

450 kW

2000

Middelgrunden

20 turbines

2,000 kW

450 kW

Height: 54 m

Rotor diameter: 37 m

Output: 0.45 MW

2007

Burbo Bank

25 turbines

3,600 kW

2002

Samsø

10 turbines

2,300 kW

G2 platform

Height: 100 – 125 m

Rotor diameter: 82 – 101 m (offshore)

Output: 2.0 – 2.3 MW

G4 platform

Height: 130 – 155 m

Rotor diameter: 107 – 130 m

Output: 3.6 – 4.0 MW

D7 platform

Height: 175 – 185 m

Rotor diameter: 120 – 154 m

Output: 6.0 – 7.0 MW

History in the making

Total number of Siemens turbines installed offshore

While rigorous testing drives the development of ever more powerful platforms,

offshore experience is the bedrock on

which investment robustness is built.

Starting in 1991, Siemens has a track

record that no other provider can match.

1991. The Vindeby Wind Farm

Turbine Technology

Installing the world’s first offshore wind

power plant was a move into uncharted

waters, in more ways than one. New

procedures were required for installation,

operations, and maintenance. What’s

more, offshore experts were in short

supply. In 1991, Siemens had just 11

wind-power engineers. Nevertheless,

this small team of specialists was able to

tailor onshore technology to the demands

of offshore – and make the groundbreaking first deployment a success.

Onshore technology thrives offshore

On July 11, 1991, Vindeby Offshore Wind

Farm delivered its first power to the grid –

a historic day in the renewable energy

industry. With a combined capacity of

5 megawatts, its 11 turbines exceeded

all expectations, consistently producing

20 percent more electricity than equivalent onshore wind power plants.

After decades of production, the same

turbines are still in operation today.

Turbine type

Bonus 450 kW

Farm size

11 turbines

Capacity

4.95 MW

Location

Lolland, Denmark

Owner

DONG Energy

11 turbines

Offshore’s most

experienced engineers

Because rust never sleeps

Jens Thomsen came to Siemens from the

maritime industry in the early 1990s, to

work as a design technician on the new

Vindeby turbines. From his maritime

experience, he was in no doubt about the

scale of the challenges ahead. For example, the salty and humid sea air makes

conditions ideal for corrosion, a major

cause of structural damage, short circuits,

and leakages. In the mind of the young

engineer, the decision to pursue a career

installing high-tech mechanical structures

in the hostile offshore environment was

as brave as it was potentially fulfilling.

Undaunted, Jens devised an innovative,

twofold strategy to minimize the risk of

Vindeby Offshore Wind Farm

1991

corrosion. First, he had specially developed seals and dehumidifiers installed in

the tower and nacelle. This prevented salt

entering the structure and kept humidity

in check inside the turbine. Second, to

complete the corrosion-control process,

his team treated every metal surface with

a protective paint developed in cooperation with Danish coating specialists

Hempel.

This solution was designed to last 20 years

and in 2011 tests indicated the turbines

were indeed corrosion-free. Vindeby

remains in operation to this day, just as

Jens Thomsen remains one of Siemens’

most senior – and expert – offshore

engineers.

“My goal is to cut

costs for customers by

providing state-of-theart solutions.”

Jens Thomsen

The Bonus 450 kW wind turbine at a glance

•Three-bladed upwind turbine

•Geared asynchronous generator

•Stall fixed pitch and fixed speed

•Directly connected to the grid

10

11

From kilowatts to

megawatts

Turbine Technology

Learning from the 450 kW platform

design used at Vindeby, over the coming

decade Siemens continued to evolve its

platform and service portfolio, which did

not distinguish between offshore and

onshore platforms until the introduction

of the G4.

12

At a glance

• Upwind turbine

• Three-bladed

• Geared

• Asynchronous generator

• Stall pitch

• Direct connection to the grid

1995. The 600 kW platform

At a glance

• Upwind turbine

• Three-bladed

• Geared

• Asynchronous generator

• COMBISTALL® pitch

• Direct connection to the grid

1996. The 1,000 kW platform

The first 600 kW platform featured a reinforced bedplate and one main bearing

instead of the two bearings on the 450

kW platform. The stationary drivetrain

design was discarded in favor of a new

design with a rotating main shaft. The

gearbox was moved further back and separated from the main shaft by a coupling,

while the cooling system was optimized

to regulate the temperature of the gear

oil. In addition, the 600 kW introduced a

new yaw system based on an innovative

slide-bearing design with claws.

The 1,000 kW platform formed the basis

of four different wind turbines: the 1,000

kW, the 1,300 kW, the 2,000 kW, and the

2,300 kW. It also prepared the way for a

quantum leap in turbine design. The next

generation of turbines would adapt to

the varying needs of the grid by replacing

COMBISTALL® pitch control with Variable

Speed, made possible by the NetConverter® technology that made its debut

on the next platform – the G2.

G2

Total number of Siemens turbines installed offshore

1995

11 turbines

1999. The G2 platform

Superior serviceability

By the late 1990s, Siemens had acquired

nearly a decade of in-depth offshore

expertise. The success of the Vindeby

wind park project underlined the importance of two key features that differed

significantly from onshore operations:

lightning protection and serviceability.

Wind is significantly colder at hub height

than at ground level so the Vindeby

turbines featured a movable shield to

shelter service technicians while they

worked. Siemens’ G2 generation of offshore turbines incorporated an enhanced

version of the shield that, together with

further improvements based on operational experience at Vindeby, maintained

excellent working conditions for service

personnel.

Enhanced lightning protection

If lightning passes through the inner

workings of a wind turbine, the result is

immediate failure. The lightning protection system installed at Vindeby had

proved its worth for these relatively small

turbines, but an even more robust system

was required to protect the larger rotor

blades of higher-capacity models that

would attract more frequent lightning

strikes. The solution was an enhanced

system that integrated lightning receptors

within the structure of the blades. These

controlled where lightning struck the

turbine while insulated circuits channeled

the current down to the sea.

2000

31 turbines

At a glance

• Upwind turbine

• Three-bladed

• Geared

• Asynchronous generator

• Pitch regulated

• AC-DC-AC connection to the grid

13

The first dedicated

offshore turbine

2004. The G4 platform

The evolution of a revolution

In 2004, Siemens launched the G4

platform with the introduction of the

SWT-3.6-107, the first offshore wind turbine developed specifically for offshore

energy production. All turbines based

on the G4 platform benefit from the separation of mechanical components from

the nacelle canopy, an innovation that

offers enhanced protection against the

offshore environment. It is just one of the

features that has helped make the G4

the world’s most commercially successful

wind turbine platform.

In 2007, the best-selling SWT-3.6-107

was replaced by the SWT-3.6-120, which

generated more power thanks to a larger

rotor. In 2014, the launch of the 4-megawatt SWT-4.0-130 marked the culmination

of a steady process of innovation and

refinement of geared wind turbine technology. The strengths of the SWT-4.0-130

were confirmed when investors approved

its selection for the 600 MW Gemini wind

power plant in the North Sea, the largestever project-financed offshore wind

power project to that date.

The G4 platform benefits from state-of-theart IntegralBlade® technology that eliminates glue joints to deliver blades with the

optimum balance of size, quality, strength,

and reliability – without compromising the

turbine’s structural load.

Total number of Siemens turbines installed offshore

2001

2005

2010

45 turbines

117 turbines

500 turbines

The future of offshore

wind power technology:

direct drive

Turbine Technology

At a glance

• Upwind turbine

• Three-bladed

• IntegralBlade® technology

• Geared

• Asynchronous generator

• Pitch regulated

• AC-DC-AC connection to the grid

G4

Performance and profitability

In the ongoing search for cost-effective solutions, the late 2000s saw Siemens’

resourceful engineers adapt direct drive technology from another branch of renewable

energy: hydroelectricity. Direct drive dispenses with the gearbox to reduce complexity, enhance simplicity, and boost efficiency.

Gearless efficiency

Replacing the gearbox, the coupling, and the high-speed generator with a low-speed

generator eliminates two-thirds of the conventional geared drive train arrangement.

As a result, Siemens direct drive turbines comprise up to 50 percent fewer rotating and

wear-prone parts than comparable geared models.

Simplicity and accessibility

Siemens direct drive also benefits from permanent magnet excitation of the generator,

which is regarded as the simplest and most efficient generator design. The simplicity

reduces the weight of the turbine and gives service technicians more space inside the

nacelle, making key components more easily accessible.

Future proven

Siemens direct drive technology is the culmination of a holistic philosophy that balances

design, material choice, processes, manufacture, assembly, and installation – all in

order to maximize reliability. Siemens has been validating the technology since 2008,

with a combination of field-operation and dedicated laboratory testing. In 2009, the

first Siemens D3 direct drive turbines went successfully into operation. They were

followed in 2011 by the first version of the D7 platform.

14

15

A different breed of

turbine: the Siemens D7

16

Total number of Siemens turbines installed offshore

2011

655 turbines

2011. The D7 platform, version 1

The leanest machine

2015. The D7 platform, version 2

Smooth operators

True to Siemens’ ongoing cycle philosophy, the wind turbines in the D7 platform

incorporate the aggregate offshore

know-how of the last quarter-century.

Designed to IEC I requirements, D7 turbines can potentially be deployed in any

known offshore location. Key technologies

were transferred from the tried-and-tested

D3 and G4 platforms and the structural

capacity of all the components was verified by full-scale testing. The first version

of the D7 carries a rating of 6 megawatts.

Weight was a core factor in the D7 platform design from the very start. Hereby it

delivers significant savings on substructure, shipping, and installation – and

raises returns on investment.

When Siemens engineers set about optimizing the D7 platform, four years of

operational experience showed that an

incremental upgrade of the electrical

system allowed for increasing the generator rating by 17 percent. The upgraded

version of the D7 wind turbine retains the

basic structure, and all the advantages,

of its 6-megawatt predecessor, but still

generates up to 10 percent more power.

Despite the upgrade, the overall turbine

dimensions of the SWT-7.0-154 remain

unchanged. This generates valuable

synergies in project development, and

reduces operational risk – for example,

by minimizing impact on the existing

balance-of-plant supply chain.

Like the first offshore turbines installed

by the Siemens team back in 1991, the

D7 platform is tailored specifically to offshore applications. Every exposed surface

and system features offshore-grade

corrosion protection, like the enclosed

nacelle, which is fitted with internal

climate control.

2015

1,766 turbines

Turbine Technology

At a glance

• Upwind turbine

• Three-bladed

• IntegralBlade® technology

• Gearless

• Synchronous direct drive generator

• Pitch regulated

• AC-DC-AC connection to the grid

D7

17

Committed to robust

offshore returns

Powered by partnership

Investment Robustness

As a pioneer and thought leader in the offshore industry, Siemens has accumulated

unrivaled experience in adapting to the challenges that arise when implementing

rapidly advancing technologies.

As Siemens has strived to transform the wind power sector, however, one thing

has never changed: the company’s commitment to its partners. In addition to safety,

your return on investment is Siemens’ first priority. With a combination of state-ofthe-art turbine technology, ever-higher quality standards, innovative service concepts,

continuous testing, and ongoing research, Siemens is committed to consistently

delivering on its promises.

You can rely on the support of Siemens teams throughout the entire lifetime of

your investment. Siemens employees constantly pursue innovation and improve on

proven products, ensure reliability, and tailor an extensive service portfolio to your

specific needs.

With thousands of turbines installed offshore, and a total capa­city of more than

6 GW (as of 2015), Siemens has a vested interest in maintaining sustainable partnerships. You can rest assured that you will receive all the professional support required

to maximize the security of your wind power investment over the long term.

18

Published by

Siemens AG

Wind Power and Renewables

Lindenplatz 2

20099 Hamburg, Germany

siemens.com/wind

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax: +49 180 524 24 71

(Charges depending on provider)

Email: support.energy@siemens.com

Article-No. WPOF-B90001-00-4A00

Printed in Germany

Dispo 34804

RS1501210ROTBR10150.5

All rights reserved.

Subject to change without prior notice.

Trademarks mentioned in this document are the property

of Siemens AG, its affiliates, or their respective owners.

The information in this document contains general

descriptions of the technical options available, which

may not apply in all cases. The required technical

options should therefore be specified in the contract.