Quantitative Review III

advertisement

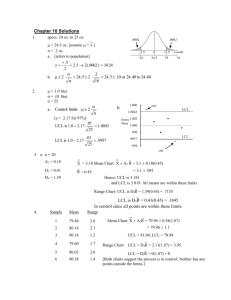

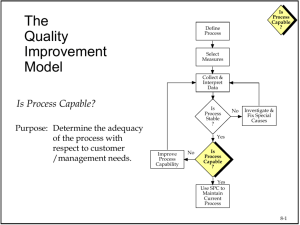

Quantitative Review III Chapter 6 & 6S Managing Quality & Statistical Process Control (SPC) How do we ensure quality of manufacturing and service delivery processes? Using Statistical Process Control (SPC) to help identify and eliminate unwanted causes of variation in the process To monitor the degree of product conformance to a specification on continuous scale of measurement such as length, weight, and time (continuous metric), we use X-bar and R-charts. To monitor the noncontinous scale of measurement (discrete metric)such as from data that are counted (e.g. no. of compete orders, no. of good service experiences), we use p- or c-charts Control Charts for Variable Data (length, width, etc.) • Mean (x-bar) charts – Tracks the central tendency (the average or mean value observed) over time • Range (R) charts: – Tracks the spread of the distribution over time (estimates the observed variation) Control Charts for Variable Data (length, width, etc.) K: Number of samples n: Sample size x i : The mean for each sample (sample average) R: the range for each sample x : The overall mean of all the sample means R : The average range of all the sample ranges x x 1 x 2 ... x n k Upper Control Limit: Lower Control Limit: UCL LCL x x x z x z x x ; x n standard deviation of the sample means standard deviation of the process x x “n” = # of observations in each sample n x 1 x 2 ... x n k z “k” = # of samples = standard normal variable or the # of std. deviations desired to use to develop the control limits Example: X Bar-Chart Assume the standard deviation of the process is given as 1.13 ounces Management wants a 3-sigma chart (only 0.26% chance of alpha error) Observed values shown in the table are in ounces. Calculate the UCL and LCL. Sample 1 Sample 2 Sample 3 Observation 1 15.8 16.1 16.0 Observation 2 16.0 16.0 15.9 Observation 3 15.8 15.8 15.9 Observation 4 15.9 15.9 15.8 Sample means 15.875 15.975 15.9 x 15 . 875 15 . 975 15 . 9 3 We have 3 samples here x 15 . 9167 x 1 . 13 4 1 . 13 2 . 565 We have 4 observations in each sample UCL 15 . 9167 3 x . 565 17 . 62 ounces LCL 15 . 9167 3 x . 565 14 . 23 ounces Example: X Bar-Chart Inspectors want to develop process control charts to measure the weight of crates of wood. Data (in pounds) from three samples are: Sample Crate 1 Crate 2 Crate 3 Crate 4 1 18 38 22 26 2 26 30 28 20 3 26 26 26 26 What are the upper and lower x control limits for this process? Z=3 = 4.27 We first need to calculate x-bar for each sample x1 = 18 38 22 26 = 26 4 x2 = 26 30 28 20 = 26 4 x3 = 26 26 26 26 4 = 26 26 26 26 x 26 3 We have 3 samples x 4 . 27 4 4 . 27 2 . 135 2 We have 4 observations in each sample UCL 26 3 x 2 . 135 32 . 4 LCL 26 3 x 2 . 135 19 . 6 Range or R Chart UCL R D4R, R R LCL R D3R k = # of sample ranges k Range Chart measures the dispersion or variance of the process while The X-Bar chart measures the central tendency of the process. When selecting D4 and D3 from the table, use sample size or number of observations for n. Control Chart Factors Sample Size (n) 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Factors for R-Chart D4 D3 0.00 3.27 0.00 2.57 0.00 2.28 0.00 2.11 0.00 2.00 0.08 1.92 0.14 1.86 0.18 1.82 0.22 1.78 0.26 1.74 0.28 1.72 0.31 1.69 0.33 1.67 0.35 1.65 Example: R-Chart Sample 1 Sample 2 Sample 3 Observation 1 15.8 16.1 16.0 Observation 2 16.0 16.0 15.9 Observation 3 15.8 15.8 15.9 Observation 4 15.9 15.9 15.8 Sample means 15.875 15.975 15.9 Sample ranges 0.2 0.3 0.2 Sample ranges = highest observation – lowest observation R-chart Computations (Use D3 & D4 Factors: Table 6-1) R 0 .2 0 .3 0 .2 3 . 233 D4 from control chart factors when n=4 UCL R R D 4 . 233 2 . 28 . 531 LCL R R D 3 . 233 0 0 D3 from control chart factors when n=4 Example: R-Chart Ten samples of 5 observations each have been taken form a Soft drink bottling plant in order to test for volume dispersion in the bottling process. The average sample range was found To be .5 ounces. Develop control limits for the sample range. R = 0.5, n = 5 UCL R R D 4 ( 0 . 5 )( 2 . 11 ) 1 . 055 LCL R R D 3 0 . 5 0 0 P- Chart Many quality characteristics assumes only two values, such as good or bad, pass or fail. The proportion of nonconforming items can be monitored using a control chart called a p-chart, where p is the proportion of nonconforming items found in a sample. (P) Fraction Defective Chart • Used for yes or no type judgments (acceptable/not acceptable, works/doesn’t work, on time/late, etc.) • p = proportion of nonconforming items p = average proportion of nonconforming items (P) Fraction Defective Chart total number p total number p UCL z p (1 p ) n p p z p , of defects of units sampled(" , k" times" n" ) K = # of samples n = # of observations in each sample LCL p p z p = standard normal variable or the # of std. deviations desired to use to develop the control limits P-Chart Example: A Production manager for a tire company has inspected the number of defective tires in five random samples with 20 tires in each sample. The table below shows the number of defective tires in each sample of 20 tires. Z= 3. Calculate the control limits. Sample Number of Defective Tires Number of Tires in each Sample Proportion Defective 1 3 20 .15 2 2 20 .10 3 1 20 .05 4 2 20 .10 5 1 20 .05 Total 9 100 .09 Solution: p # Defectives Total Inspected σp p (1 p ) n 9 .09 100 (.09)(.91) 0.064 20 UCL p p z σ .09 3(.064) .282 LCL p p z σ .09 3(.064) .102 0 Note: Lower control limit can’t be negative, if LCLp is less than zero, a value of zero is used. C-Chart A p-chart monitors the proportion of nonconforming items, but a nonconforming item may have more than one conformance. E.g. a customer’s order may have several errors, such as wrong item, wrong quantity, wrong price. To monitor the number of nonconformance per unit, we use a c-chart. It is used extensively in service applications. Number-of-Defectives or C-Chart Used when looking at # of nonconformances c = # of nonconformances c = average # of nonconformances per sample Number-of-Defectives or C Chart c number of incidents observed number of samples (k) , c c UCL c c z c c z c LCL c c z c c z c z = standard normal variable or the # of std. deviations desired to use to develop the control limits C-Chart Example: The number of weekly customer complaints are monitored in a large hotel using a c-chart. Develop three sigma control limits using the data table below. Z=3. Week Number of Complaints 1 3 2 2 3 3 4 1 5 3 6 3 7 2 8 1 9 3 10 1 Total 22 Solution: _ c # complaints # of samples 22 2.2 10 UCL c c z c 2.2 3 2.2 6.65 LCL c c z c 2.2 3 2.2 2.25 0 Process Capability The natural variation in a process that results from common causes Process Capability Index A measure that quantify the relationship between the natural variation and specifications Process Capability • Product Specifications – Preset product or service dimensions, tolerances – e.g. bottle fill might be 16 oz. ±.2 oz. (15.8oz.-16.2oz.) – Based on how product is to be used or what the customer expects • Process Capability – Cp and Cpk – Assessing capability involves evaluating process variability relative to preset product or service specifications – Cp assumes that the process is centered in the specification range Cp specificat ion width process width USL LSL 6σ – Cpk helps to address a possible lack of centering of the process USL μ μ LSL C pk min , 3σ 3σ Process Capability LSL USL Spec Width -3δ -2δ -1δ μ 1δ 2δ 3δ Cp specificat ion width USL LSL process width C pk USL μ μ LSL min , 3σ 3σ 6σ If Cp is ≥ 1; process capable of meeting design specs If Cpk is ≥ 1; process capable of meeting design specs Process Capability Index • Can a process or system meet it’s requirements? Cp product' s design specificat ion range 6 standard deviations of the production USL - LSL system 6 Cp < 1: process not capable of meeting design specs Cp ≥ 1: process capable of meeting design specs One shortcoming, Cp assumes that the process is centered on the specification range USL μ μ LSL C pk min , 3σ 3σ min = minimum of the two = mu or mean of the process If C pk is less than 1, then the process is not capable or is not centered. Capability Indexes • Centered Process (Cp): Cp specificat ion width process width USL LSL 6 • Any Process (Cpk): USL LSL C pk min ; 3 3 Cp=Cpk when process is centered Example • Design specifications call for a target value of 16.0 +/-0.2 ounces (USL = 16.2 & LSL = 15.8) • Observed process output has a mean of 15.9 and a standard deviation of 0.1 ounces Computations • C p: Cp USL LSL 6 16 . 2 15 . 8 6 0 . 1 0 .4 0 . 66 0 .6 Cp < 1: process not capable of meeting design specs • Cpk: LSL USL C pk min or 3 3 16 . 2 15 . 9 15 . 9 15 . 8 min or 3 0 . 1 3 0 . 1 0 .1 0 .3 min or min 1 or 0 . 33 0 . 33 0 .3 0 .3 C pk <1, then this measure also indicates that process is not capable Chapter 3 Project Management Project Planning, Scheduling and Controlling Calculate Path Durations P a th s ABD EG H JK A B D E G IJ K AC FG H JK A C F G IJ K P a th d u ra tio n 40 41 22 23 • The longest path (ABDEGIJK) limits the project’s duration (project cannot finish in less time than its longest path) • ABDEGIJK is the project’s critical path ES=10 ES=16 ES=4 Project Network EF=16 EF=30 EF=10 LS=16 LS=10 E Buffer LS=4 LF=30 LF=16 LF=10 B(6) A(4) D(6) ES=32 EF=34 LS=33 LF=35 E(14) H(2) G(2) ES=35 EF=39 LS=35 LF=39 ES=39 EF=41 LS=39 LF=41 J(4) K(2) ES=0 ES=30 C(3) EF=4 F(5) EF=32 I(3) LS=0 LS=30 ES=4 LF=4 ES=7 LF=32 ES=32 EF=7 Critical Path: the sequence of activities that takes the longest time & EF=12 LS=22defines the total project completion EF=35 time LS=25 LF=25 LS=32 LF=30 LF=35 Calculate Early Starts & Finishes ES=10 EF=16 ES=4 EF=10 B(6) D(6) E(14) Latest EF H(2) = Next ES A(4) G(2) ES=0 EF=4 LS=0 LF=4 ES=32 EF=34 ES=16 EF=30 C(3) ES=4 EF=7F=25 F(5) ES=7 EF=12 LS=25 LF=30 J(4) ES=30 EF=32 LS=30 LF=32 ES=35 EF=39 I(3) ES=32 EF=35 LS=32 LF=35 ES=39 EF=41 K(2) Calculate Late Starts & Finishes ES=10 EF=16 LS=10 LF=16 ES=4 EF=10 LS=4 LF=10 B(6) D(6) E(14) A(4) ES=0 EF=4 LS=0 LF=4 ES=32 EF=34 LS=33 LF=35 ES=16 EF=30 LS=16 LF=30 H(2) G(2) C(3) ES=4 EF=7 LS=22 LF=25 F(5) ES=7 EF=12 LS=25 LF=30 ES=30 EF=32 LS=30 LF=32 ES=35 EF=39 LS=35 LF=39 J(4) I(3) ES=32 EF=35 LS=32 LF=35 ES=39 EF=41 LS=39 LF=41 K(2) What is the critical path? E(5) B(3) G(4) A(4) C(5) D(2) F(6) 1. 2. 3. 4. ABEGH ACEGH ACFGH ADFGH H(3) What is ES, EF for G? E(5) B(3) G(4) A(4) C(5) D(2) F(6) 1. 2. 3. 4. 14, 18 15, 19 16, 20 17, 21 Latest EF = Next ES H(3) What is LS, LF for C? E(5) B(3) G(4) A(4) C(5) D(2) F(6) 1. 2. 3. 4. 4, 9 5, 10 3, 8 6, 11 H(3) ES 9 LS 10 EF 14 LF 15 ES 4 LS 7 EF 7 LF 10 ES 19 LS 19 EF 22 LF 22 E(5) B(3) ES 15 LS 15 EF 19 LF 19 ES 4 LS 4 EF 9 LF 9 ES 0 EF 4 H(3) G(4) C(5) A4 D2 ES 4 LS 7 EF 6 LF 9 F(6) ES 9 LS 9 EF 15 LF 15 Latest EF = Next ES Earliest LS = Previous LF Activity Slack Time TES = earliest start time for activity TLS = latest start time for activity TEF = earliest finish time for activity TLF = latest finish time for activity Activity Slack = TLS - TES = TLF - TEF Calculate Activity Slack Ac tiv ity A B C D E F G H I J K L a te E a rly S la c k F in is h 4 10 25 16 30 30 32 35 35 39 41 F in is h 4 10 7 16 30 12 32 34 35 39 41 (w e e k s ) 0 0 18 0 0 18 0 1 0 0 0 Path Slack Duration of Critical Path (41) - Path Duration = Path Slack P ath s A B D E G H JK A B D E G IJK A C F G H JK A C F G IJK P ath d u ratio n 40 41 22 23 Path Slack 1 0 19 18 Consider the following project information. Activity Activity Time (weeks) Immediate Predecessor(s) A 3 none B 5 A C 2 B D 5 B E 12 C, D F 3 E G 6 E H 5 G, F What is the critical path? A (3) B (5) It is ABDEGH C (2) E (12) D (5) F (3) G (6) H(5) A (3) B (5) C (2) E (12) D (5) F (3) G (6) H(5) What is ES and EF for E? ES for E: 3+5+5=13 EF for E: 13+12 =25 What is LS and LF for C? LF for C: = ES for E =13 LS for C: 13-2=11 What is the activity slack for C? ES for C: 3+5 =8 Activity slack for C = LS-ES=11-8=3 EF for C: 8+2=10 If as a project manager you see that Activity F in the project above is going to take 3 extra weeks, what should you do? Watchful waiting Waiting Line Models How long you wait in line depends on a number of Factors: 1. the number of people served before you 2. the number of servers working 3. the amount of time it takes to serve each individual customer Wait time is affected by the design of the waiting line system. A waiting line system (or queuing system) is defined by two elements: • The customer population (people or objects to be processed) • The process or service system Waiting Line System Performance Measures • The average number of customers waiting in queue • The average number of customers in the system • The average waiting time in queue • The average time in the system • The system utilization rate (% of time servers are busy) Infinite Population, Single-Server, Single Line, Single Phase Formulae lambda mean arrival rate mu mean service rate L average system utilizatio n average number of customers in system Infinite Population, Single-Server, Single Line, Single Phase Formulae L Q L average number of customers W 1 average time in system in line including service W Q W average time spent waiting in line Pn 1 n probabilit y of n customers Do not confuse L from LQ ; or W from WQ in the system Example • A help desk in the computer lab serves students on a first-come, first served basis. On average, 15 students need help every hour. The help desk can serve an average of 20 students per hour. Assess the performance measures in this case. Based on this description, we know: – μ= 20 (exponential distribution) – λ= 15 (Poisson distribution) - Average System Utilization 15 0 . 75 or 75 % 20 - Average Number of Students in the System L 15 20 15 3 students - Average Number of Students Waiting in Line L Q L 0 . 75 3 2 . 25 students - Average Time a Student Spends in the System W 1 1 20 15 = .2 hours or 12 minutes - Average Time a Student Spends Waiting (Before Service) W Q W 0 . 75 0 . 2 0 . 15 hours or 9 minutes - Probability of n Students in the Line P0 1 P1 1 0 1 1 0 . 75 1 0 . 25 1 0 . 75 0 . 75 0 . 188 P2 1 2 1 0 . 75 0 . 75 2 0 . 141 P3 1 3 1 0 . 75 0 . 75 3 0 . 105 P4 1 4 1 0 . 75 0 . 75 4 0 . 079 Example Consider a single-server queuing system. If the arrival rate is 40 units per hour, and each customer takes 60 seconds on average to be served, what is the average # of customers in the line? Answer to 2 decimal places. λ = 40 units/ hr; μ = (60 *60)/60 = 60 units / hr Average number of customers in the line LQ = ρL = (λ /μ) * (λ /μ-λ) = (40/60)*(40/20) =1.33 Example Consider a single-line, single-server waiting line system. Suppose that customers arrive according to a Poisson distribution at an average rate of 60 per hour, and the average (exponentially distributed) service time is 36 seconds per customer. What is the average number of customers in the system? Should they add servers? λ = 60 customers/hour Service rate is 36 seconds for each customer, so μ =60*60 / 36 = 100 customers / hour The average number of customers in the system L = λ / (μ-λ) = 60 / (100-60) =1.5, no need to add servers Example Consider a single-server queuing system. If the arrival rate is 25 customers per hour and it takes 3 minutes on average to serve a customer, what is the average waiting time in the waiting line in minutes? λ= 25 customers/hr, μ = 60/3 =20 customers/hr WQ = ρW=(λ/μ)(1/μ-λ) =(25/20)(1/20-25) =-.25 Answer: the waiting time will continuously increase Example Consider a single-line, single-server waiting line system. The arrival rate lambda is 80 people per hour, and the service rate µ is 120 people per hour. What is the probability of having 3 units in the system? ρ = λ/μ= 80/120 =.66 Probability Pn = (1- ρ)ρn =(1-.66) (.66^3) =(.33)(.287) = .0947 =9.47%