Quality Control

advertisement

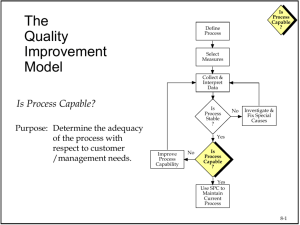

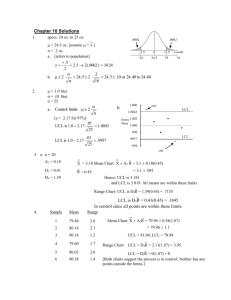

Statistical Process Control Operations Management Dr. Ron Lembke Designed Size 10 11 12 13 14 15 16 17 18 19 20 Natural Variation 14.5 14.6 14.7 14.8 14.9 15.0 15.1 15.2 15.3 15.4 Theoretical Basis of Control Charts Properties of normal distribution 95.5% of allX fall within ± 2 X Theoretical Basis of Control Charts Properties of normal distribution 99.7% of allX fall within ± 3 X 16 14 12 10 8 6 4 2 0 Skewness Lack of symmetry Pearson’s coefficient of skewness: 3( x Median ) s Positive Skew > 0 16 14 12 10 8 6 4 2 0 Skewness = 0 Negative Skew < 0 16 14 12 10 8 6 4 2 0 0.45 Kurtosis 0.4 0.35 0.3 0.25 0.2 Amount of peakedness or flatness (x x) 4 0.15 0.1 0.05 0 -6 -4 -2 0 Kurtosis = 0 ns4 Kurtosis < 0 2 Kurtosis > 0 4 6 Heteroskedasticity Sub-groups with different variances Design Tolerances Design tolerance: Determined by users’ needs USL -- Upper Specification Limit LSL -- Lower Specification Limit Eg: specified size +/- 0.005 inches No connection between tolerance and completely unrelated to natural variation. Process Capability and 6 LSL USL 3 LSL USL 6 A “capable” process has USL and LSL 3 or more standard deviations away from the mean, or 3σ. 99.7% (or more) of product is acceptable to customers Process Capability Capable Not Capable LSL USL LSL USL LSL USL LSL USL Process Capability Specs: 1.5 +/- 0.01 Mean: 1.505 Std. Dev. = 0.002 Are we in trouble? Process Capability Specs: 1.5 +/- 0.01 LSL = 1.5 – 0.01 = 1.49 USL = 1.5 + 0.01 = 1.51 Mean: 1.505 Std. Dev. = 0.002 LCL = 1.505 - 3*0.002 = 1.499 UCL = 1.505 + 0.006 = 1.511 Process Specs 1.49 1.499 1.51 1.511 Capability Index Capability Index (Cpk) will tell the position of the control limits relative to the design specifications. Cpk>= 1.33, process is capable Cpk< 1.33, process is not capable Process Capability, Cpk Tells how well parts produced fit into specs C pk X LSL USL X min or 3 3 Process Specs LSL 3 X 3 USL Process Capability Tells how well parts produced fit into specs C pk X LSL USL X min or 3 3 For our example: 1.505 1.49 1.51 1.505 C pk min or 0.006 0.006 Cpk= min[ 0.015/.006, 0.005/0.006] Cpk= min[2.5,0.833] = 0.833 < 1.33 Process not capable Process Capability: Re-centered If process were properly centered Specs: 1.5 +/- 0.01 LTL = 1.5 – 0.01 = 1.49 UTL = 1.5 + 0.01 = 1.51 Mean: 1.5 Std. Dev. = 0.002 LCL = 1.5 - 3*0.002 = 1.494 UCL = 1.5 + 0.006 = 1.506 Process Specs 1.49 1.494 1.506 1.51 If re-centered, it would be Capable C pk C pk 1.5 1.49 1.51 1.5 min , 0.006 0.006 0.01 0.01 min , 1.67 0.006 0.006 Process Specs 1.49 1.494 1.506 1.51 Packaged Goods What are the Tolerance Levels? What we have to do to measure capability? What are the sources of variability? Production Process Make Candy Make Candy Make Candy Mix Package Put in big bags Wrong wt. Wrong wt. Make Candy Mix % Make Candy Make Candy Candy irregularity Processes Involved Candy Manufacturing: Mixing: Is proper color mix in each bag? Individual packages: Are M&Ms uniform size & weight? Should be easier with plain than peanut Percentage of broken items (probably from printing) Are same # put in each package? Is same weight put in each package? Large bags: Are same number of packages put in each bag? Is same weight put in each bag? Weighing Package and all candies Before placing candy on scale, press “ON/TARE” button Wait for 0.00 to appear If it doesn’t say “g”, press Cal/Mode button a few times Write weight down on form Candy colors 1. 2. 3. 4. 5. 6. 7. Write Name on form Write weight on form Write Package # on form Count # of each color and write on form Count total # of candies and write on form (Advanced only): Eat candies Turn in forms and complete wrappers The effects of rounding 25.00 0.80 24.00 g - rounded oz - rounded 23.00 0.7 Ounces 0.70 Rounded Weight - Ounces Rounded Weight - grams 22.00 21 grams 21.00 20 grams 20.00 0.6 Ounces 0.60 19 grams 19.00 18 grams 18.00 17.00 0.50 14.5 15.0 15.5 16.0 16.5 17.0 17.5 18.0 18.5 19.0 Original Weight in grams 19.5 20.0 20.5 21.0 21.5 22.0 22.5 Peanut Candy Weights Avg. 2.18, stdv 0.242, c.v. = 0.111 Peanut Individuals 9 8 7 6 Count 5 4 3 2 1 0 1.5 1.6 1.7 1.8 1.9 2 2.1 2.2 2.3 Mass (g) 2.4 2.5 2.6 2.7 2.8 2.9 3 Plain Candy Weights Avg 0.858, StDev 0.035, C.V. 0.0413 Individual Plain Candies 16 14 12 10 8 6 4 2 0 0. 78 0. 79 0. 8 0. 81 0. 82 0. 83 0. 84 0. 85 0. 86 0. 87 0. 88 0. 89 0. 9 0. 91 0. 92 0. 93 0. 94 0. 95 0. 96 0. 97 Count Mass (g) Peanut Color Mix Brown 17.7% Yellow 8.2% Red 9.5% Blue 15.4% Orange 26.4% Green 22.7% website 20% 20% 20% 20% 10% 10% Plain Color Mix Brown Yellow Red Blue Orange Green Class 12.1% 14.7% 11.4% 19.5% 21.2% 21.2% website 30% 20% 20% 10% 10% 10% So who cares? Dept. of Commerce National Institutes of Standards & Technology NIST Handbook 133 Fair Packaging and Labeling Act Acceptable? Package Weight “Not Labeled for Individual Retail Sale” If individual is 18g MAV is 10% = 1.8g Nothing can be below 18g – 1.8g = 16.2g Goal of Control Charts See if process is “in control” Process should show random values No trends or unlikely patterns Visual representation much easier to interpret Tables of data – any patterns? Spot trends, unlikely patterns easily NFL Control Chart? Control Charts Values UCL avg LCL Sample Number Definitions of Out of Control 1. 2. 3. 4. No points outside control limits Same number above & below center line Points seem to fall randomly above and below center line Most are near the center line, only a few are close to control limits 1. 2. 3. 8 Consecutive pts on one side of centerline 2 of 3 points in outer third 4 of 5 in outer two-thirds region Control Charts Normal 5 above, or below Too Low Too high Run of 5 Extreme variability Control Charts UCL 2σ 1σ avg 1σ 2σ LCL Control Charts 2 out of 3 in the outer third Out of Control Point? Is there an “assignable cause?” If not usual variability, GET IT OUT Or day-to-day variability? Remove data point from data set, and recalculate control limits If it is regular, day-to-day variability, LEAVE IT IN Include it when calculating control limits Attribute Control Charts Tell us whether points in tolerance or not p chart: percentage with given characteristic (usually whether defective or not) np chart: number of units with characteristic c chart: count # of occurrences in a fixed area of opportunity (defects per car) u chart: # of events in a changeable area of opportunity (sq. yards of paper drawn from a machine) Attributes vs. Variables Attributes: Good / bad, works / doesn’t count % bad (P chart) count # defects / item (C chart) Variables: measure length, weight, temperature (x-bar chart) measure variability in length (R chart) p Chart Control Limits UCLp p z p 1 p n k p X i i1 k n i1 i # Defective Items in Sample i Sample i Size p Chart Control Limits UCLp p z p 1 p n k k n # Samples n i1 k i p X i i1 k n i1 i z = 2 for 95.5% limits; z = 3 for 99.7% limits # Defective Items in Sample i Sample i Size p Chart Control Limits UCLp p z LCL p p z k n # Samples n i1 k i p 1 p n p 1 p n k p X i i1 k n i1 i z = 2 for 95.5% limits; z = 3 for 99.7% limits # Defective Items in Sample i Sample i Size p Chart Example You’re manager of a 1,700 room hotel. For 7 days, you collect data on the readiness of all of the rooms that someone checked out of. Is the process in control (use z = 3)? © 1995 Corel Corp. p Chart Hotel Data Day 1 2 3 4 5 6 7 # Rooms n 1,300 800 400 350 300 400 600 No. Not Proportion Ready p 130 130/1,300 =.100 90 .113 21 .053 25 .071 18 .06 12 .03 30 .05 p Chart Control Limits k n n i 1 1300 800... 600 4,150 592.8 7 7 i k k p X i 1 k n i 1 i 130 90... 30 326 0.079 4,150 4,150 i p (0.10 0.113 ... 0.05) / 7 .068 p Chart Solution p 0.069, n 592.8 p 1 p n p 1 p 0.079 1 0.079 CL p z 0.079 3 n 592.8 0.079 3 * 0.0111 0.079 0.0333 UCL 0.1123, LCL 0.0457 Hotel Room Readiness P-Bar 0.12 0.1 0.08 UCL 0.06 Actual LCL 0.04 0.02 0 1 2 3 4 5 6 7 R Chart Type of variables control chart Shows sample ranges over time Interval or ratio scaled numerical data Difference between smallest & largest values in inspection sample Monitors variability in process Example: Weigh samples of coffee & compute ranges of samples; Plot Hotel Example You’re manager of a 500room hotel. You want to analyze the time it takes to deliver luggage to the room. For 7 days, you collect data on 5 deliveries per day. Is the process in control? Hotel Data Day Delivery Time 1 7.30 4.20 6.10 3.45 2 4.60 8.70 7.60 4.43 3 5.98 2.92 6.20 4.20 4 7.20 5.10 5.19 6.80 5 4.00 4.50 5.50 1.89 6 10.10 8.10 6.50 5.06 7 6.77 5.08 5.90 6.90 5.55 7.62 5.10 4.21 4.46 6.94 9.30 R &X Chart Hotel Data Day Delivery Time 1 7.30 4.20 6.10 3.45 5.55 Sample Mean Range 5.32 7.30 + 4.20 + 6.10 + 3.45 + 5.55 Sample Mean = 5 R &X Chart Hotel Data Day Delivery Time 1 7.30 4.20 6.10 3.45 5.55 Largest Smallest Sample Mean Range 5.32 3.85 Sample Range = 7.30 - 3.45 R &X Chart Hotel Data Day 1 7.30 2 4.60 3 5.98 4 7.20 5 4.00 6 10.10 7 6.77 Delivery Time 4.20 6.10 3.45 8.70 7.60 4.43 2.92 6.20 4.20 5.10 5.19 6.80 4.50 5.50 1.89 8.10 6.50 5.06 5.08 5.90 6.90 5.55 7.62 5.10 4.21 4.46 6.94 9.30 Sample Mean Range 5.32 3.85 6.59 4.27 4.88 3.28 5.70 2.99 4.07 3.61 7.34 5.04 6.79 4.22 R Chart Control Limits UCLR D4 R Table 10.3, p.433 LCLR D3 R k R Ri i 1 k Sample Range at Time i # Samples Control Chart Limits n A2 D3 D4 2 1.88 0 3.278 3 1.02 0 2.57 4 0.73 0 2.28 5 0.58 0 2.11 6 0.48 0 2.00 7 0.42 0.08 1.92 R Chart Control Limits k R R i 1 k i 3.85 4.27 ... 4.22 3.894 7 UCLR D4 * R 2.11* 3.894 8.232 LCLR D3 * R 0 * 3.894 0 D3 , D4 fromT able10.3 R Chart Solution R, Minutes 8 6 4 2 0 1 2 UCL 3 4 Day 5 6 7 X Chart Control Limits UCLX X A2 R Sample Mean at Time i k X X i 1 k k i R R i 1 k i Sample Range at Time i # Samples X Chart Control Limits A2 from Table 10-3 UCLX X A2 R LCLX X A2 R k X X i 1 k k i R R i 1 k i Table 10.3 Limits n A2 D3 D4 2 1.88 0 3.278 3 1.02 0 2.57 4 0.73 0 2.28 5 0.58 0 2.11 6 0.48 0 2.00 7 0.42 0.08 1.92 R &X Chart Hotel Data Day 1 7.30 2 4.60 3 5.98 4 7.20 5 4.00 6 10.10 7 6.77 Delivery Time 4.20 6.10 3.45 8.70 7.60 4.43 2.92 6.20 4.20 5.10 5.19 6.80 4.50 5.50 1.89 8.10 6.50 5.06 5.08 5.90 6.90 5.55 7.62 5.10 4.21 4.46 6.94 9.30 Sample Mean Range 5.32 3.85 6.59 4.27 4.88 3.28 5.70 2.99 4.07 3.61 7.34 5.04 6.79 4.22 X Chart Control Limits k X X i 1 k i 5.32 6.59 ... 6.79 5.813 7 k R R i 1 k i 3.85 4.27 ... 4.22 3.894 7 UCLX X A2 * R 5.813 0.58* 3.894 8.060 LCLX X A2 * R 5.813 0.58* 3.894 3.566 X Chart Solution* X, Minutes 8 6 4 2 0 1 2 3 UCL LCL 4 Day 5 6 7