Roland Caulcutt

advertisement

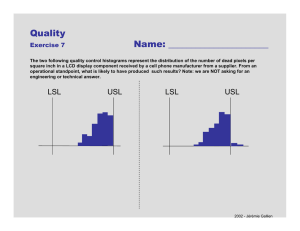

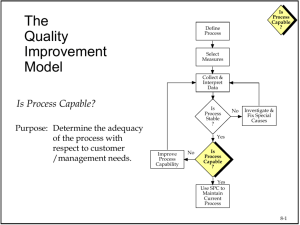

Measurement error Roland Caulcutt Caulcutt Associates Two processes Materials Information Production process Products/services Measurement process Data A process is a combination of equipment, people and procedures that work together to produce products and services. All of your data comes from measurement processes. 2 Measurement error Many people wish to believe that measurement error does not exist. These people measure something once and assume that the measurement is “correct”. They believe that taking a second measurement would be pointless. 3 Repeat measurements 15.6 15.8 16.0 16.2 16.4 Length (cm) Spread The spread of repeat measurements quantifies the precision of the measurement process. 4 To assess precision We could use: Spread = range of data We use: Spread = 6sd. 15.6 15.8 16.0 Range 16.2 16.4 Length (cm) 6 sd 5 Precision If the measurements were made by the same person, using the same equipment, then: The spread is a measure of repeatability. If the measurements were made by different people then: The spread is a measure of reproducibility or R&R. 6 VIM International vocabulary of metrology (VIM) - 2008 The VIM defines repeatability and reproducibility. If everyone adopted these definitions there would be no ambiguity. Component manufacturers do accept them but many chemical manufacturers don’t. They prefer to focus on the difference that might exist if producer and customer measure the same delivery. 7 How good is your measurement process? The capability of your measurement process will depend on how you intend to use the data it produces. You might use data to help you to: 1. Control a production process 2. Assess the capability of a production process 3. Improve a production process 4. Classify products or services 5. Settle customer/supplier disputes 8 Relative precision To make your assessment of precision more meaningful you could relate it to the purpose of your measurement. If you are measuring in order to classify product you could express your spread as a % of the specification. If you are measuring in order to improve the production process you could: Express your spread as a % of your product variation. Calculate number of distinct categories 9 Classification of product Because of measurement error you may be left in doubt about the acceptability of the product or service. Uncertainty Uncertainty ????? ????? Not acceptable Not acceptable Acceptable LSL USL Quality 10 R&R as a % of specification R&R = 100% LSL USL LSL USL LSL USL LSL USL R&R = 30% R&R = 10% R&R = 0% 11 GUM Guide to the expression of uncertainty in measurement (GUM) We make one measurement. It is extremely unlikely that the measured value will be equal to the true value. We report an interval in which we are confident that the true value will lie. (True value) = (Measured value) + k(SD) 12 Bias True value Mean 15.6 15.8 16.0 16.2 16.4 Length (cm) Bias Bias may be a bigger source of error than poor precision. 13 Thank you for your attention. 14