PRODUCTIONS/OPERATIONS MANAGEMENT

Chapter 6 – Part 4

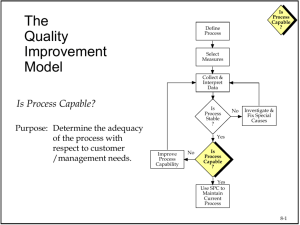

Process Capability

Meaning of Process Capability

The capability of a process is the ability of the process to meet the specifications.

A process is capability of meeting the specification limits if at least 99.73

% of the product falls within the specification limits.

This means that the fraction of product that falls outside the specification limits is no greater than

0.0027, or that no more that 3 out of 1,000 units is

“out of spec.”

Our method of computing process capability assumes that the process is normally distributed.

Control Limits vs. Spec. Limits

Control limits apply to sample means, not individual values.

Mean diameter of sample of 5 parts, X bar

Spec limits apply to individual values

Diameter of an individual part, X

Control Limits vs. Spec. Limits

Sampling distribution,

X-bar

Process distribution,

X

LSL

Lower control limit

Mean=

Target

Upper control limit

USL

Requirements for Assessing

Process Capability

To assess capability of a process, the process must be in statistical control.

That is, all special causes of variation must be removed prior to assessing capability.

Also, process performance characteristic

(e.g., diameter, bake time) must be normally distributed.

C p

Index

Cp

USL

6

ˆ

LSL

USL = upper specification limit

LSL = Lower specification limit

ˆ estimated process standard deviation

C p

Index

6

ˆ spread of the process

USL - LSL

width of the spec.

limits

• We want the spread (variability) of the process to be as ???

• If the spread of the process is very ????, the capability of the process will be very ????

C p

Index

LSL X

Width of spec limits = USL - LSL

USL

Spread of Process = USL - LSL

Process distribution,

X

Process is Barely Capable if Cp = 1

.9973

.00135

.00135

LSL USL

X

X

Spread of process matches the width of specs.

99.73% of output is within the spec. limits.

Process Barely Capable if Cp = 1

spec. limits?

LSL =

USL =

Process Barely Capable if Cp = 1

Cp

X

USL

6

ˆ

LSL

3

6

ˆ

( X

3

)

X

6

6

ˆ

3

6

ˆ

X

1

3

Process is Capable if Cp > 1

>.9973

< .00135

USL

< .00135

X

LSL X

Spread of process is less than the width of specs.

More than 99.73% of output is within the spec. limits.

Process is Not Capable if Cp < 1

< .9973

> .00135

> .00135

LSL USL

X

X

Spread of process is greater than the width of specs.

Less than 99.73% of output is within the spec. limits.

Estimating the Standard Deviation

LCL

X

3

ˆ n

UCL

X

3

ˆ n

LCL

X

A

2

R

UCL

X

A

2

R

Estimating the Standard Deviation

3

ˆ n

A

2

R

ˆ

A

2

R

3 n

Sugar Example Ch. 6 - 3

Day Hour X1 X2 X3 X

1 10 am 17 13 6 36/3 =12

1 pm 15 12 24 51/3 =17

4 pm 12 21 15 48/3 =16

2 10 am 13 12 17 42/3 =14

1 pm 18 21 15 54/3 =18

R

11

12

9

5

6

4 pm 10 18 17 45/3 =15

X = 92/6

= 15.33

8

R = 51/6

= 8.5

R

8 .

5 , n

3 , A

2

1 .

02

ˆ

A

2

R

3 n

( 1 .

02 )( 8 .

5 )

3

15 .

0169

3

5 .

0

3

Capability of Sugar Process

USL = 20 grams

LSL = 10 grams

ˆ

5 .

0

Cp

USL

6

ˆ

LSL

20

10

6 ( 5 )

10

30

0 .

33

Capability of Sugar Process

Since C p

<1, the process is not capability of meeting the spec limits.

The fraction of defective drinks (drinks with either too much or not enough sugar) will exceed .0027.

That is, more than 3 out of every 1000 drinks produced can be expected to be too sweet or not sweet enough.

We now estimate the process fraction defective, p -bar.

Estimated Process Fraction Defective

What is the estimated process fraction defective -the percentage of product out of spec?

p -bar = F1 + F2

F1

LSL USL

F2

Mean

Estimated Process Fraction Defective

We can then use Cp to determine the p -bar because there is a simple relationship between Cp and z : z = 3 C p

(See last side for deviation of this result.)

•

Suppose, C p

= 0.627

z = 3(0.627) =1.88

Estimated Process Fraction Defective

The z value tells us how many standard deviations the specification limits are away from the mean.

A z value of 1.88 indicates that the USL is 1.88 standard deviations above the mean.

The negative of z , -1.88, indicates that the LSL is

1.88 standard deviations below the mean.

We let

Area( z ) be the area under the standard normal curve between 0 and z .

Process Fraction Defective

Area( z ) = Area(1.88) = 0.4699

LSL USL

F

2

0 z = 1.88

F

2

= % above USL = .5000 - 0.4699 = .0301

.

.

0.2

.09

1.8

z

0.0

0.1

z Table (Text, p. 652)

.00

.01

.02

.

.

.

.08

.09

.4699

Process Fallout pbar = 2[.5 – Area( z )] = F1 + F2

F1

LSL

0

0.4699

USL z = 1.88

F2 pbar = 2(.5 – .4699) = 2(.0301)=.0602

Process Fallout – Two Sided Spec.

Cp

0.25

z = 3 Cp Fallout =

2[.5 – Area(z)]

Defect Rate in

PPM (parts per million)

0.75

2[.5-.2734] = .4532 453,200 PPM

0.80

1.0

1.5

2.40

2[.5-.4918] = .0164

16,400 PPM

3

-4.5

From

Excel

2[.5-.4987] = .0026

2,600 PPM

7 PPM 2[Area(z )]=

2[.0000034]

=.0000068

Recommended Minimum Cp

Process Cp z = 3 Cp

Existing process

New process

1.25

3.75

Fallout

2[Area(-z)]=

2[.000088]

=.0001769

1.45

4.35

2[Area(-z)]=

2[.000006812]

=.0000136

PPM

176.9

13.6

Recommended Minimum Cp

Process Cp z = 3 Cp

Safety, existing process

Safety, new process

Fallout

1.45

4.35

2[Area(-z)]=

2[.000006812]

=.0000136

1.60

4.80

2[Area(-z)]=

2[.000000794]

=0.0000016

PPM

13.6

1.6

Soft Drink Example

Cp = 0.33

z = 3 Cp = 3(0.33) = 0.99

Area( z ) = Area(0.99) = 0.3389

p -bar = 2[.5 - Area(0.99)]

= 2[.5 - 0.3389]

= 0.3222

Capability Index Based on Target

• Limitation of C p is that it assumes that the process is mean is on target.

Process Mean = Target Value = (LSL + USL)/2

C

T

Capability Index

With Cp, capability value is the same whether the process is centered on target or is way off.

Cp is not affected by location of mean relative to target.

We need capability index that accounts for location of the mean relative to the target as well as the variance.

C

T is an index that accounts for the location of mean relative to target.

C

T

Capability Index

C

T

6

USL

LSL

ˆ

( X

Target)

2

C

T

Capability Index

If process is centered on target,

X

Target

( X

Target)

2

0

C

T

??

If process is off target,

X

T arget

C

T

C p

Example of C

T

LSL = 10, USL = 20, estimated standard deviation =

5.0 and estimate process mean = 15.33. Compute

C

T

.

C

T

6

USL

LSL

ˆ

( X

Target)

2

6

20

10

5

( 15 .

33

15 )

2

.

3326

C

T

Capability Index

If process mean is adjusted to target,

C

T

6

USL

LSL

ˆ

( X

Target)

2

6 0 .

3

14

10

( 12

12 )

2

2 .

2

C p

C

T

Capability Index

C p is the largest value that C

T can equal.

Since C p

= 2.2 and C

T

= .44, the difference

D

C p

C

T

.

3333

.

3326

0 .

0007 is the maximum amount by which we can increase

C

T by adjusting the mean to the target value.

Conclusion?

Derivation of z = 3Cp

C

p

X

2 z

ˆ z

6

ˆ

USL z

ˆ

6

ˆ

(

6

ˆ

LSL

X

3 z

ˆ

) z

3 C p