Manufacturing Operations Management

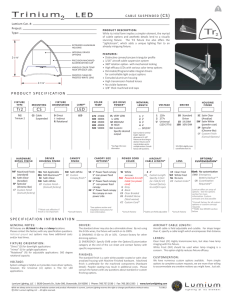

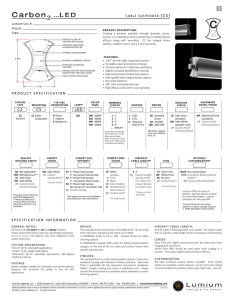

advertisement

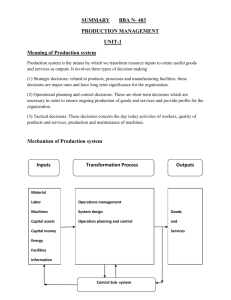

Manufacturing Operations Management BY AMAR P. NARKHEDE Manufacturing Operations Management Production/operations management is the process, which combines and transforms various resources used in the production/operations subsystem of the organization into value added product/services in a controlled manner as per the policies of the organization. Therefore, it is that part of an organization, which is concerned with the transformation of a range of inputs into the required (products/services) having the requisite quality level. The set of interrelated management activities, which are involved in manufacturing certain products, is called as production management. If the same concept is extended to services management, then the corresponding set of management activities is called as service operations management. Manufacturing Operations Management For over two centuries operations and production management has been recognised as an important factor in a country’s economic growth. The traditional view of manufacturing management began in eighteenth century when Adam Smith recognised the economic benefits of specialisation of labour. He recommended breaking of jobs down into subtasks and reorganised workers to specialised tasks in which they would become highly skilled and efficient. In the early twentieth century, F.W. Taylor implemented Smith’s theories and developed scientific management. From then till 1930, many techniques were developed prevailing the traditional view. Manufacturing Operations Management Production management becomes the acceptable term from 1930s to 1950s. As F.W. Taylor’s works become more widely known, managers developed techniques that focused on economic efficiency in manufacturing. Workers were studied in great detail to eliminate wasteful efforts and achieve greater efficiency. At the same time, psychologists, socialists and other social scientists began to study people and human behaviour in the working environment. In addition, economists, mathematicians, and computer specialists contributed newer, more sophisticated analytical approaches. With the 1970s emerges two distinct changes in our views. The most obvious of these, reflected in the new name operations management was a shift in the service and manufacturing sectors of the economy. As service sector became more prominent, the change from ‘production’ to ‘operations’ emphasized the broadening of our field to service organizations. The second, more suitable change was the beginning of an emphasis on synthesis, rather than just analysis, in management practices. Manufacturing Operations Management Evolution of Factory System The factory system was a method of manufacturing first adopted in England at the beginning of the Industrial Revolution in the 1750s and later spread abroad. Fundamentally, each worker created a separate part of the total assembly of a product, thus increasing the efficiency of factories. Workers, paid by wage, and machines were brought together in a central factory. All the processes of production would be carried out under one roof, and would continue as long as it was practical Manufacturing Operations Management The factory system was largely responsible for the rise of the modern city, as large numbers of workers migrated into the cities in search of employment in the factories. Nowhere was this better illustrated than the mills and associated industries of Manchester, nicknamed "Cotton polis", and arguably the world's first industrial city. For much of the 19th century, production was done in small mills, which were typically water-powered and built to serve local needs. Later each factory would have its own steam engine and a chimney to give an efficient draft through its boiler. The transition to industrialization was not without difficulty. For example, a group of English workers known as Luddites formed to protest against industrialization and sometimes sabotaged factories. They continued a tradition already established where new machines threatened existing jobs. Numerous inventors in the textile industry such as John Kay and Samuel Crompton for example, suffered harassment when developing their machines or devices. Manufacturing Operations Management Types of Manufacturing Systems •Custom Manufacturing •Intermittent Manufacturing •Continuous Manufacturing •Flexible Manufacturing Manufacturing Operations Management Custom Manufacturing This is one of the oldest manufacturing systems in the world because it goes back to when products where first made. Basically custom manufacturing is where one person has the skill that is needed to make a certain product. A great example of this type of manufacturing is a shoe maker or a candle maker; it used to be that only one person was required to make these customized products. Custom manufacturing is still used today but rather than just one person making the product that is required we have machines that will do the jobs for us. And if people are doing the manufacturing you are going to need more than one person to make the specialized product so you can keep up with the higher demands. Manufacturing Operations Management Intermittent Manufacturing This is also an older style of a manufacturing system. This system was used when custom manufacturing could not meet the demands of the customers. Basically what intermittent manufacturing is where more than one of the same product is being made. This type of manufacturing is actually used world wide and it is a great way to make more than one product in a short amount of time, as long as the product is the same product. This type of manufacturing won't work on multiple products. A great example of this type of manufacturing is making five pairs of the same shoe rather than one custom pair of shoes. Manufacturing Operations Management Continuous Manufacturing This is a newer system of manufacturing and it was created when product demands got to be too much for intermittent manufacturing. Basically this manufacturing system is an actual assembly line. This system is usually used when more then one product is being made and it takes more than two people working together to actually make the product. In this type of manufacturing system the product moves from one station to the next and each person at each station has a specific job that they need to do in the manufacturing process. This type of manufacturing system is great if you are producing a product that requires you to complete a lot of steps before it can be considered a finished product, but the drawback to this type of manufacturing system is that it can be expensive to run. Manufacturing Operations Management Flexible Manufacturing This is actually the newest type of manufacturing system that is being used currently. This type of manufacturing system uses machines that are controlled by computers. This type of manufacturing produces a product just like intermitted manufacturing and is continuous like continuous manufacturing, but the thing about this type of manufacturing system is that it cuts out having to hire people for an assembly line. Not to mention that it is also a great way to always make the product faster with consistent quality which is a great way to keep up with the customers demands. Manufacturing Operations Management Manufacturing Quality Quality control is a process by which entities review the quality of all factors involved in production. This approach places an emphasis on three aspects: Elements such as controls, job management, defined and well managed processes, performance and integrity criteria, and identification of records Competence, such as knowledge, skills, experience, and qualifications Soft elements, such as personnel integrity, confidence, organizational culture, motivation, team spirit, and quality relationships. The quality of the outputs is at risk if any of these three aspects is deficient in any way. Manufacturing Operations Management Manufacturing Quality Quality Control emphasizes testing of products to uncover defects, and reporting to management who make the decision to allow or deny the release, whereas Quality Assurance attempts to improve and stabilize production, and associated processes, to avoid, or at least minimize, issues that led to the defects in the first place Manufacturing Operations Management Mass Customization Mass customization can be described as "enabling a customer to decide the exact specification of a product or service, and have that product or service supplied to them at a price close to that for an ordinary mass produced alternative". Manufacturing Operations Management What is PRODUCTION? Production function is that part of an organization, which is concerned with the transformation of a range of inputs into the required outputs (products) having the requisite quality level. Manufacturing Operations Management Definition of PRODUCTION Production is defined as “the step-by-step conversion of one form of material into another form through chemical or mechanical process to create or enhance the utility of the product to the user.” Thus production is a value addition process. At each stage of processing, there will be value addition. Manufacturing Operations Management Inputs • Men •Material •Capital •Information •Machines Transformation Process • Product Design •Process Planning •Production Control •Maintenance Continuous •Inventory •Quality •Cost Schematic Design of a simple Production system Output •Products •Services Manufacturing Operations Management Characteristics of a Production System 1. Production is an organized activity, so every production system has an objective. 2. The system transforms the various inputs to useful outputs. 3. It does not operate in isolation from the other organization system. 4. There exists a feedback about the activities, which is essential to control and improve system performance.