prod-mgmt-summary

advertisement

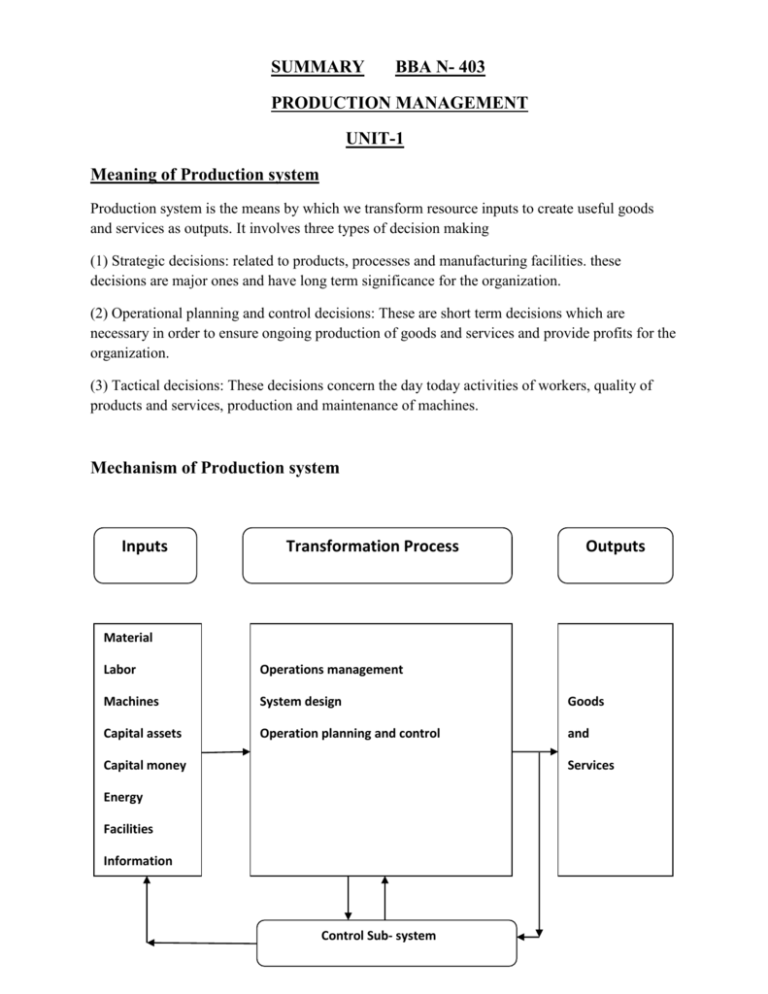

SUMMARY BBA N- 403 PRODUCTION MANAGEMENT UNIT-1 Meaning of Production system Production system is the means by which we transform resource inputs to create useful goods and services as outputs. It involves three types of decision making (1) Strategic decisions: related to products, processes and manufacturing facilities. these decisions are major ones and have long term significance for the organization. (2) Operational planning and control decisions: These are short term decisions which are necessary in order to ensure ongoing production of goods and services and provide profits for the organization. (3) Tactical decisions: These decisions concern the day today activities of workers, quality of products and services, production and maintenance of machines. Mechanism of Production system Inputs Transformation Process Outputs Material Labor Operations management Machines System design Goods Capital assets Operation planning and control and Capital money Services Energy Facilities Information Control Sub- system Manufacturing system A combination of all activities and operations to produce some goods and services is known as manufacturing systems. Manufacturing system can be divided into two categories – (a) Intermittent system (b) Continuous system Intermittent system Intermittent systems are those where the production facilities are flexible enough to handle wide variety of products and services. Characteristics are as follows (i) It is flexible to suit production varieties (ii) Most products are produced in small quatities (iii) Machines and equipments are laid out by process focused system (iv)Physical facilities are organized around the nature of processes (v) Personnel are specialized by generic process type. (vi) In process inventory is large (vii) Workloads are generally unbalanced Intermittent system of production can be classified into two categories: Job production batch production Job Production Whole product is taken as a single operation versatile and skilled labour is required high capital investment high unit cost of production Control operations are relatively simple Batch Production Items are produced to definite customer orders and not for stock more specialized labour is required low capital investment Continuous system In this system the items are produced for the stocks and not for specific orders. Characteristics of continuous system are as follows:(i) The product in continuous system is standardized. (ii) Material should be as per specifications and delivered in time. (iii) There must be continuity of demand (iv) Continuous system is more focused when product is demanded in more volume. (v) All operations must be balanced (vi) Appropriate plant and machinery must be provided (vii) Work must confirm to quality standards Continuous system can be of two types a) Mass production b) Process production Mass production: - It is generally used to manufacture sub assemblies or particular parts of an item. These parts are assembled together by the enterprise to get a final product. Standardization is fundamental characteristic of this system. Process production:- This method is used to produce those items whose demand is continuous and high e.g. petroleum products,chemical industries,medicines etc. Product development and design “A product is a bundle of physical service and symbolic particulars expected to yield satisfaction or benefits to buyer”. here are two types of products:a) b) Consumer products i. Convenience goods ii. shopping goods iii. speciality goods Industrial products Definition of Product Development “Product development is that system through and by which new products are launched in the markets to fulfill the expectations of existing markets” Principles of Product development Standardization Simplification Specialization Stages of New Product Development Creation of new product ideas Commercializatio n of product Evaluation of ideas Decision to accept the project Testing the product Failure of New product Inadequate market analysis product defect higher cost poor timing competition insufficient marketing effort inadequate sales forecast weakness in distribution Definition of Product design “Product designs provide much needed variety in terms of the features and the appearance. An appropriate product design also helps an organization to compete in the market place on the basis of cost, quality and time”.