Product and

Service Design

McGraw-Hill/Irwin

Copyright © 2012 by The McGraw-Hill Companies, Inc. All rights reserved.

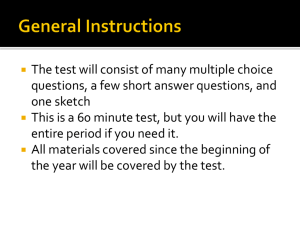

You should be able to:

1.

Explain the strategic importance of product and service design

2. Identify some key reasons for design or redesign

3. Recognize the key questions of product and service design

4. List some of the main sources of design ideas

5. Discuss the importance of legal, ethical, and sustainability

considerations in product and service design

6. Explain the purpose and goal of life cycle assessment

7. Explain the phrase “the 3 Rs”

8. Briefly describe the phases in product design and development

9. Name several key issues in manufacturing design

10. Recognize several key issues in service design

11. Name the phases in service design

12. List the characteristics of well-designed service systems

13. Assess some of the challenges of service design

Student Slides

4-2

The essence of an organization is the goods and services it

offers

Every aspect of the organization is structured around

them

Product and service design – or redesign – should be

closely tied to an organization’s strategy

Student Slides

4-3

Stages of product/service design:

Functional design (form, shape, size, materials,

etc.)

Process design (processing technology and

tooling)

Production design (production line & plant

layout)

Product/service quality

Production/delivery cost

Customer satisfaction

1.

Is there a demand for it?

Market size

Demand profile

2.

Can we do it (competence)?

Manufacturability - the capability of an organization to

produce an item at an acceptable profit

Serviceability - the capability of an organization to provide

a service at an acceptable cost or profit

3.

What level of quality is appropriate?

Customer expectations

Competitor quality

Fit with current offering

4.

Does it make sense from an economic standpoint?

Liability issues, ethical considerations, sustainability issues,

costs and profits

Student Slides

4-6

Developing New Products/Services

Sources of Product Innovation

Getting Them to Market Faster

Designing and Developing New Services

Improving Current Products/Services

Designing for Ease of Production

Designing for Quality

Customers

Managers

Marketing

Operations

Engineering

Research and Development (R&D)

Basic research

Applied research

1. Technical and economic feasibility studies

2. Prototype design

3. Performance testing of prototype

4. Market sensing/evaluation and economic evaluation

of the prototype

5. Design of production model

6. Market/performance/process testing and economic

evaluation of production model

7. Continuous modification of production model

1. Technical and Economic Feasibility Studies

Determine the advisability of establishing a project for

developing the product

If initial feasibility studies are favorable, engineers

prepare an initial prototype design

2. Prototype Design

This design should exhibit the basic form, fit, and

function of the final product

It will not necessarily be identical to the production

model

3. Performance Testing of Prototype

Performance testing and redesign of the prototype

continues until this design-test-redesign process

produces a satisfactorily performing prototype

4. Market Sensing/Evaluation and Economic

Evaluation of the Prototype

Accomplished by demonstrations to potential

customers, market test, or market surveys

If the response to the prototype is favorable, economic

evaluation of the prototype is performed to estimate

production volume, costs, and profits

If the economic evaluation is favorable, the project

enters the production design phase.

5. Design of Production Model

The initial design of the production model will not be

the final design; the model will evolve

6. Market/Performance/Process Testing and

Economic Evaluation of Production Model

The production model should exhibit:

low cost

reliable quality

superior performance

the ability to be produced in the desired quantities on the

intended equipment

7. Continuous Modification of Production Model

Production designs are continuously modified to:

Adapt to changing market conditions

Adapt to changing production technology

Allow for manufacturing improvements

About 5% of all new-product ideas survive to

production, and only about 10% of these are

successful.

It is best to cancel unpromising newproduct/service development projects early!

Employees often become emotionally caught up

in these projects and are overly optimistic

An impartial management review board is needed

for periodic reviews of the progress of these

projects.

Speed creates competitive advantages

Speed saves money

Tools to improve speed:

Autonomous design and development teams

Computer-aided design/computer-aided

manufacturing (CAD/CAM)

Simultaneous (concurrent) engineering

Autonomous Design and Development Teams

Teams are given decision-making responsibility and

more freedom to design and introduce new

products/services

Time-to-market has been slashed dramatically

Enormous sums of money have been saved

Teams do not have to deal with the bureaucratic red tape

ordinarily required to obtain approvals

Computer-Aided Design/Computer-Aided

Manufacturing (CAD/CAM)

Engineers, using CAD/CAM, can generate many views of

parts, rotate images, magnify views, and check for

interference between parts

Part designs can be stored in a data base for use on other

products

When it is time for manufacturing, the product design is

retrieved, translated into a language that production

machinery understands, and then the production

system can be automatically set up.

Simultaneous

(Concurrent)

Engineering

Product/

Service Ideas

Economic and Technical

Feasibility Studies

Product/Service Design

Continuous

Interaction

Production Process Design

Produce and Market

New Product/Service

Focus is improving performance, quality, and cost

Objective is maintaining or improving market

share of maturing products/services

Little changes can be significant

Small, steady (continuous) improvements can add

up to huge long-term improvements

Value analysis is practiced, meaning design

features are examined in terms of their

cost/benefit (value).

Ease of Production (Manufacturability)

Specifications - Precise information about the

characteristics of the product

Tolerances - Minimum & maximum limits on a dimension

that allows the item to function as designed

Standardization - Reduce variety among a group of

products or parts

Simplification - Reduce or eliminate the complexity of a

part or product

Crucial element of product design is its impact on

quality

Quality is determined by the customer’s

perception of the degree of excellence of the

product/service’s characteristics

Chapter 7 covers the principles of designing

products/services for quality

Three general dimensions of service design are:

Degree of Standardization of the Service

Custom-fashioned for particular customers or basically

the same for all customers?

Degree of Customer Contact in Delivering the

Service

High level of contact (dress boutique) or low level (fast-

food restaurant)?

Mix of Physical Goods and Intangible Services

Mix dominated by physical goods (tailor’s shop) or by

intangible services (university)?

Differences Between New Service and New

Product Development

Unless services are dominated by physical goods, their

development usually does not require engineering,

testing, and prototype building.

Because many service businesses involve intangible

services, market sensing tends to be more by surveys

rather than by market tests and demonstrations.

Legal considerations

Ethical considerations

Human factors

Cultural factors

Global product and service design

Environmental factors

Others

Student Slides

4-27

Sustainability

Using resources in ways that do not harm ecological systems that

support human existence

Key aspects of designing for sustainability

Cradle-to-grave assessment (Life-Cycle assessment)

End-of-life programs

The 3-Rs

Reduction of costs and materials used

Re-using parts of returned products

Recycling

Student Slides

4-28

Value analysis

Examination of the function of parts and materials in an effort to

reduce the cost and/or improve the performance of a product

Common questions used in value analysis

Is the item necessary; does it have value; could it be eliminated?

Are there alternative sources for the item?

Could another material, part, or service be used instead?

Can two or more parts be combined?

Can specifications be less stringent to save time or money?

Do suppliers/providers have suggestions for improvements?

Can packaging be improved or made less costly?

Student Slides

4-29

Remanufacturing

Refurbishing used products by replacing worn-out or defective

components

Can be performed by the original manufacturer or another company

Reasons to remanufacture:

Remanufactured products can be sold for about 50% of the cost of a

new product

The process requires mostly unskilled and semi-skilled workers

In the global market, European lawmakers are increasingly requiring

manufacturers to take back used products

Design for disassembly (DFD)

Designing a product to that used products can be easily taken apart

Student Slides

4-30

Recycling

Recovering materials for future use

Applies to manufactured parts

Also applies to materials used during production

Why recycle?

Cost savings

Environmental concerns

Environmental regulations

Companies doing business in the EU must show that a specified

proportion of their products are recyclable

Design for recycling (DFR)

Product design that takes into account the ability to

disassemble a used product to recover the recylcable parts

Student Slides

4-31