CE444 – Chemical Process Control

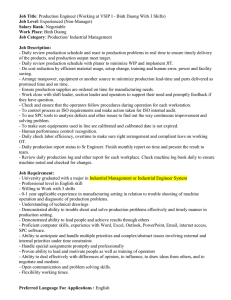

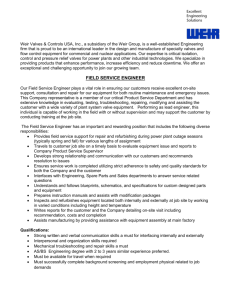

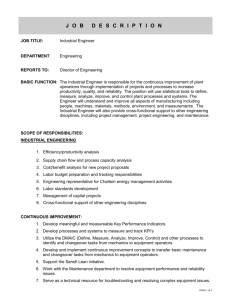

advertisement

CE-307 – CHEMICAL ENGINEERING DESIGN CE-307 – Chemical Engineering Design Instructor – University at Buffalo Mattheos Koffas Teaching Assistant Chin Giaw (Ryan) Lim Course Information Lectures Office Hours Mondays, Wednesdays 5:00-6:20 pm 10 Capen Mondays 6:30-8:00 pm 904 Furnas Hall By appointment TA office hours Friday 4:00- 6:00 pm, 903 Furnas Hall ISBN: 0-471-00077-9 Course Grade Homework assignments Mid-term Class Tests Final examination Average will be set as C. 30% 40% 30% Note on Academic Integrity: Copying is not allowed! Homework 10 homework sets will be handed during the semester. Almost all homework (with the exception of 1) will be handed on Wednesday and will be due on Monday, 5:00 pm in class. No homework will be accepted after 5:01 pm. Course Outline Introduction Process Dynamics Laplace Transforms Transfer Function Block Diagrams Dynamic Behavior of Typical Process Systems Feedback Control Stability of Control Loops Course Objectives Review of basic process modeling. Develop dynamic models for processes and solve them. Obtain a realistic understanding of industrial process control practice. Introduction to Process Control The continuous change of measurements in a chemical or biological process leads to the conclusion that processes are dynamic. Process dynamics refer to an unsteady-state or transient behavior. Steady-state vs. unsteady-state behavior i. Steady state: variables do not change with time So far, your ChE curriculum has emphasized steady-state or equilibrium situations. Process Dynamics Only with an understanding of transient behavior of physical systems can an engineer design good processes. This is exactly what process control does: it provides the expertise needed to design plants that function well in a dynamic environment. Bottom Line: process control has a major impact on profitability Examples Continuous processes with examples of transient behavior: i. Start up & shutdown ii. Major disturbance: e.g., refinery during stormy or hurricane conditions iii. Equipment or instrument failure (e.g., pump failure) iv. Batch Processes- Batch reactor i. Composition changes with time Multidisciplinary Field Process control is used in many engineering fields: Chemical Electrical Mechanical Control The following definition of control will be used in this course: To maintain desired conditions in a physical system by adjusting selected variables in the system. What does a control system do? As an example, consider the heating system of a house. We need to maintain the house temperature at a certain point. This is done by circulating hot water through a heat exchanger. The temperature is determined by a thermostat that compares the value of the room temperature to a desired range. If the temperature is in the desired range, the pump halts water circulation. The temperature can exceed the limits, because the furnace and heat exchanger cannot respond immediately. Common features in process control cases There is always a specific value (or range) as a desired value (referred to as set point) for the controlled variable. The conditions of the system are measured; that is, all control systems use sensors to measure the physical variables that are to be maintained near the desired values. There is always a control calculation, or algorithm , which uses the measured and desired values to determine the correction to the process operation. The results of this calculation are implemented by adjusting some item of equipment in the system, which is termed the final control element. Some more definitions Input: input does not necessarily refer to material moving into the system. In Process Control, input denotes the effect of the surroundings on the chemical or biochemical process. Output:denotes the effect of the process on Input variables cause the output variables. the surroundings. Example In the heated room example, what are: The Input variable The Output variable Important terms Controlled variable: it is the variable that needs to variable. Set Point: it is the desired value of the controlled be maintained or controlled at some desired value or range. Sometimes also referred to as process variable. Thus the job of a control system is to maintain the controlled variable at its set point. Manipulated variable: is the variable used to maintain the controlled variable at its set point. Disturbance: any variable that causes the controlled variable to deviate from its set point. Also referred to as upset. Example In the room heating example, what are the: Controlled variable Manipulated variable Possible Disturbance variable(s) Why is Control necessary? Control is necessary because during its operation, a chemical plant must satisfy several requirements imposed by its designers and the general technical, economic, and social conditions in the presence of ever changing external influences (disturbances). Such requirements are the following: Safety The safe operation of a chemical process is a primary requirement for the well-being of the people in the plant and for its continued contribution to the economic development. Thus the operating pressures, temperatures, concentration of chemicals and so on should always be within allowable limits. Production specifications A plant should produce the desired amounts and quality of the final products. For example, we may require the production of 2 million pounds of ethylene per day, of 99.5% purity. Therefore, a control system is needed to ensure that the production level and the purity specifications are satisfied. Production specifications Product certification procedures (e.g., ISO9000) are used to guarantee product quality and place a large emphasis on process control. http://www.iso.ch/iso/en/ISOOnline.opener page Environmental regulations Various federal and state laws may specify that the temperatures, concentrations of chemicals and flow rates of the effluents from a plant be within certain limits. Such regulations exist for example on the amounts of SO2 that a plant can eject to the atmosphere, and on the quality of the water returned to a river or lake. Operational constraints The various types of equipments used in a chemical plant have constraints inherent to their operation. Such constraints should be satisfied throughout the operation of a plant. For example, pumps must maintain a certain net positive suction head; tanks should not overflow or go dry; distillation columns should not be flooded; the temperature in a catalytic reactor should not exceed an upper limit since the catalyst will be destroyed. Control systems are needed to satisfy these operational constraints. Economics The operation of a plant must conform with the market conditions, that is, the availability of raw materials and the demand of the final products. Furthermore it should be as economical as possible in its utilization of raw materials, energy, capital and human labor. Thus, it is required that the operating conditions are controlled at given optimum levels of minimum operating cost, maximum profit and so on. Why is control necessary? All the previous requirements dictate the need for continuous monitoring of the operation of a chemical plant and external intervention (control) to guarantee the satisfaction of the operational objectives. How is control done Control is accomplished through a rational arrangement of equipment (measuring devices, valves, controllers, computers) and human intervention (plant designers, plant operators), which together constitute a control system. Where is control implemented? The short answer to this question is: Sensors, local indicators and valves are in the process. Displays of all plant variables and control calculations are in a centralized facility. What does control engineering “engineer”? Most of the engineering decisions are introduced in the following five topics: Process Design Measurements Final elements Control structure Control calculations Process Control Design We want to design a process that we can then control well and easily. For example, we would like a chemical plant to be more responsive. By responsive we mean that the controlled variable responds quickly to adjustments in the manipulated variable. Measurements A key decision is the selection and location of sensors, because one can control only what is measured. The engineer should select sensors that measure important variables rapidly and with sufficient accuracy. Final elements We will typically consider control valves as the final elements, with the percentage opening of these valves determined by a signal sent to the valve from a controller. Control structure The engineer must decide some very basic issues in designing a control system. For example, which valve should be manipulated to control which measurement? Control calculations After the variables and control structure have been selected, equations are chosen that use the measurement and desired values in calculating the manipulated variable. As we will see, we only need to develop a few equations that we will then use to control many different types of plants. Duties of a Control Engineer Tuning controllers for performance and reliability Selecting the proper PID mode and/or advanced PID options Control loop troubleshooting Multi-unit controller design Documentation of process control changes Characteristics of Effective Process Control Engineers Use their knowledge of the process to guide process control applications Have a fundamentally sound picture of process dynamics and feedback control Work effectively with the operators Operator Acceptance A good relationship with the operators is a NECESSARY condition for the success of a control engineer Build a relationship with the operators based on mutual respect Operators are a valuable source of plant experience A successful control project should make the operators job easier, not harder Process Control and Optimization Control and optimization are terms that are many times erroneously interchanged Control has to do with adjusting flow rates to maintain the controlled variables of the process at specified set-points Optimization chooses the values for key setpoints such that the process operates at the “best” economic conditions Background needed for Process Control To be successful in the practice of automatic process control, the engineer must first be familiar with the basic principles of thermodynamics, fluid flow, heat transfer, separation process, reaction processes etc. Another important tool for the study and practice of process control is computer simulation. Many of the equations developed to describe processes are nonlinear in nature and consequently, the most exact way to solve them is by numerical methods. The computer simulation of process models is called simulation. Example Book example