Chapter 6

PLASTIC (PERMANENT) DEFORMATION

(at lower temperatures, T < T melt

/3)

• Simple tension test:

Proportional limit

Chapter 6- 14

YIELD STRENGTH,

y

y

• Stress at which

noticeable

plastic deformation has occurred.

tensile stress, when e p

= 0.002=0.2%

(just a rule of thumb or convention) e p = 0.002

engineering strain, e

Chapter 6- 15

YIELD STRENGTH: COMPARISON

y(ceramics)

>>

y(metals)

>>

y(polymers)

Room T values

Based on data in Table B4,

Callister 6e .

a = annealed hr = hot rolled ag = aged cd = cold drawn cw = cold worked qt = quenched & tempered

Chapter 6- 16

TENSILE STRENGTH, TS

• Maximum possible engineering stress in tension.

Adapted from Fig. 6.11,

Callister 6e.

Work Example

Problem 6.3

• Metals: occurs when noticeable necking starts.

• Ceramics: occurs when crack propagation starts.

• Polymers: occurs when polymer backbones are aligned and about to break.

Chapter 6- 17

TENSILE STRENGTH: COMPARISON

TS(ceram)

~ TS (met)

~ TS(comp)

>> TS(poly)

Room T values

Based on data in Table B4,

Callister 6e .

a = annealed hr = hot rolled ag = aged cd = cold drawn cw = cold worked qt = quenched & tempered

AFRE, GFRE, & CFRE = aramid, glass, & carbon fiber-reinforced epoxy composites, with 60 vol% fibers.

Chapter 6- 18

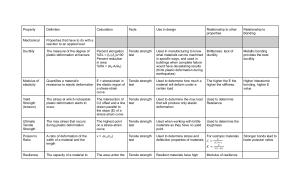

DUCTILITY, %EL

• Plastic tensile strain at failure: %EL

L f

L o

L o x100

Adapted from Fig. 6.13,

Callister 6e.

• Another ductility measure:

%AR

A o

A o

• Note: %AR and %EL are often comparable.

A f x100

--Reason: crystal slip does not change material volume.

--%AR > %EL possible if internal voids form in neck.

Chapter 619

Effect of Temperature on the Stress-

Strain Diagram

Chapter 6- 19

RESILIENCE

modulus of resilience

U r

1

2

y e y

1

2

y

E y

2 y

2 E

Resilient materials, with high yield strength and low modulus of elasticity, are used in spring applications.

Chapter 6- 19

TOUGHNESS

• Energy to break a unit volume of material

• Approximate by the area under the stress-strain curve.

• Toughness can be measured with an impact test (Izod smaller toughness (ceramics) tensile stress, larger toughness

(metals, PMCs) smaller toughness- unreinforced polymers

Engineering tensile strain, e

Chapter 620

TOUGHNESS

Toughness can be measured with an impact test (Izod or

Charpy)

Chapter 620

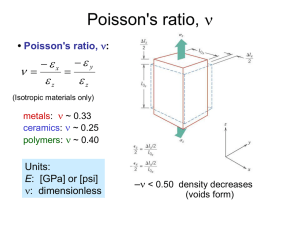

TRUE STRESS & TRUE STRAIN

Instantaneous area

1 e

T e

F

A i

, True

If volume of material is conserved during deformation: A i

Then

T

True

Stress

(

),

T

1

e

Strain

)

e

T

ln l i l

0

Instantaneous gauge length l i

=A

0 l

0 necking vali d u nti l n e ck i ng poi n t

Chapter 6- 22

EXAMPLE PROBLEM 6.4

A cylindrical specimen of steel having an original diameter of

12.8mm (0.505 in) is tensile tested to fracture and found to have an engineering fracture strength f of 460 MPa (67,000 psi). If its cross-sectional diameter at fracture is 10.7mm (0.422 in).

Determine: a) The ductility in terms of percent reduction in area b) The true stress at fracture

Chapter 6- 22

HARDENING

• An increase in y due to plastic deformation.

• Curve fit to the stress-strain response: strain

K

K and n can be found from tables or tensile tests

Chapter 622

HARDNESS

• Resistance to permanently indenting the surface.

• Large hardness means:

--resistance to plastic deformation or cracking in compression.

--better wear properties.

Adapted from Fig. 6.18, Callister 6e. (Fig. 6.18 is adapted from G.F. Kinney, Engineering Properties and Applications of Plastics, p. 202, John Wiley and Sons, 1957.)

Chapter 621

P

HARDNESS

Brinell, uses 10 mm sphere of steel or tungsten carbide

2 P

HB

D

D

D

2 d

2

Rockwell and Superficial

Rockwell, uses a diamond cone (Brale indenter) or steel spheres

Vickers microhardness, uses a diamond pyramid

HV

1 .

854 P / d

1

2

Knoop microhardness, uses a diamond pyramid

HK

14 .

2 P / l

2

Chapter 6- 21

HARDNESS and TENSILE

STRENGTH

There is a linear relation between the tensile strength and hardness of a metal (especially for cast iron, steel and brass)

For most steels:

TS ( MPa )

3 .

45

HB

TS ( psi )

500

HB

Chapter 6- 21

DESIGN OR SAFETY FACTORS

• Design uncertainties mean we do not push the limit.

• Factor of safety, N

Often N is

working

N y between

1.2 and 4

• Ex: Calculate a diameter, d, to ensure that yield does not occur in the 1045 carbon steel rod below. Use a factor of safety of 5.

working

y

N

220, 000N

d

2

/ 4

5

Chapter 623

SUMMARY

• Stress and strain : These are size-independent measures of load and displacement, respectively.

• Elastic behavior: This reversible behavior often shows a linear relation between stress and strain.

To minimize deformation, select a material with a large elastic modulus (E or G).

• Plastic behavior: This permanent deformation behavior occurs when the tensile (or compressive) uniaxial stress reaches y .

• Toughness : The energy needed to break a unit volume of material.

• Ductility : The plastic strain at failure.

Note: For materials selection cases related to mechanical behavior, see slides 22-4 to 22-10.

Chapter 624