Engineering Materials: Properties, Steels, Alloys, and More

advertisement

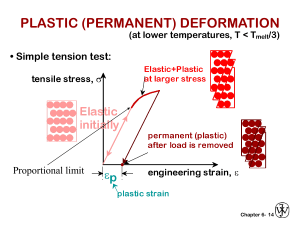

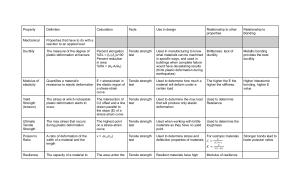

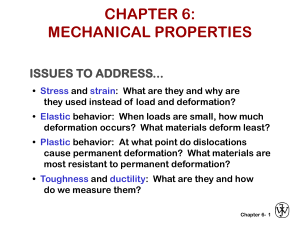

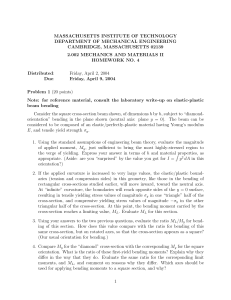

Properties of Engineering Materials Syllabus Mechanical Properties, Tensile, Fatigue, Creep, Impact, Hardness, Chemical Properties, Physical properties, Corrosion and Cathodic Protection, Carbon Steel, Low alloy Steel, High temperature and Heat Resistant Steel, Tools and High Speed Steel, Copper and Its Alloys, Aluminum Alloys, Nickel Alloys, Thermal and Insulating Materials, Engineering Inspections, Composite Materials, Plastics, Ceramics. References: 1-DONALD R. ASKELAND "THE SCIENCE AND ENGINEERING OF MATERIALS" 2-William D. Callister, Jr."MATERIALSSCIENCEAND ENGINEERING AN INTRODUCTION" 3-WILLIAM F. HOSFORD MECHANICAL BEHAVIOR OF MATERIALS 1 Mechanical Properties of Eng. Materials How do metals respond to external loads? � Stress and Strain � Tension � Compression � Shear � Torsion � Elastic deformation � Plastic Deformation � Yield Strength � Tensile Strength � Ductility � Toughness � Hardness Introduction 2 To understand and describe how materials deform(elongate, compress, twist) or break as a function of applied load, time, temperature, and other conditions we need first to discuss standard test methods and standard language for mechanical properties of materials. 3 4 5 6 7 8 9 11 11 12 The motion of dislocations 13 14 15 16 17 18 The yield strength and tensile strength vary with prior thermal and mechanical treatment, impurity levels, etc. This variability is related to the behavior of dislocations in the material. But elastic moduli are relatively insensitive to these effects. The yield and tensile strengths and modulus of elasticity decrease with increasing temperature, ductility increases with temperature. Tensile Test & the properties obtained from the 1-Tensile Test Effect of Temperature 19 2-The Bend Test for Brittle Material Due to the presence of flaw at the surface, in many brittle materials, the normal tensile test cannot easily be performed. 21 True Stress-True Strain 21 22 True Strain and True Stress 23 24 25 26 Strain Hardening σ= flow (true) stress K= Strength coefficient n =strain hardening exponent Effect of Strain Rate 𝜎 = 𝐶 𝜀∙ 𝑚 σ= flow (true) stress 𝜀=Strain rate m=strain rate sensitivity C=constant 27 Hardness Hardness is a measure of the material’s resistance to localized plastic deformation (e.g. dent or scratch) A qualitative Moh’s scale, determined by the ability of a material to scratch another material: from 1 (softest= talc) to 10 (hardest = diamond). Different types of quantitative hardness test has been designed (Rockwell, Brinell, Vickers, etc.). Usually a small indenter (sphere, cone, or pyramid) is forced into the surface of a material under conditions of controlled magnitude and rate of loading. The depth or size of indentation is measured. The tests somewhat approximate, but popular because they are easy and non-destructive (except for the small dent). 28 29 31 Both tensile strength and hardness may be regarded as degree of resistance to plastic deformation. Hardness is proportional to the tensile strength – but note that the proportionality constant is different for different materials. 31 32 33 1. Perfect elastic Fig 1.17 a: The behavior of this material is defined completely by its stiffness, indicated by the modulus of elasticity (E), example ceramic, cast iron, and thermosetting. This material is not good for forming operation. 2. Elastic and perfect plastic Fig 1.17 b: This material has stiffness defined by (E). Once the yield strength (Y) is reached, the material deforms plastically at the same stress level, flow curve K=Y and n=0. Example, lead at room temperature, material when heated to a high temperature under melting point temperatures. 3. Elastic and strain hardening Fig 1.17 c: This material obeys Hook's low in the elastic region and reach yield strength Y and then deformed by a flow curve which K<Y and n#0, example, ductile material. Figure 34 35