Solid Materials Glossary

advertisement

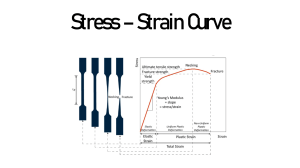

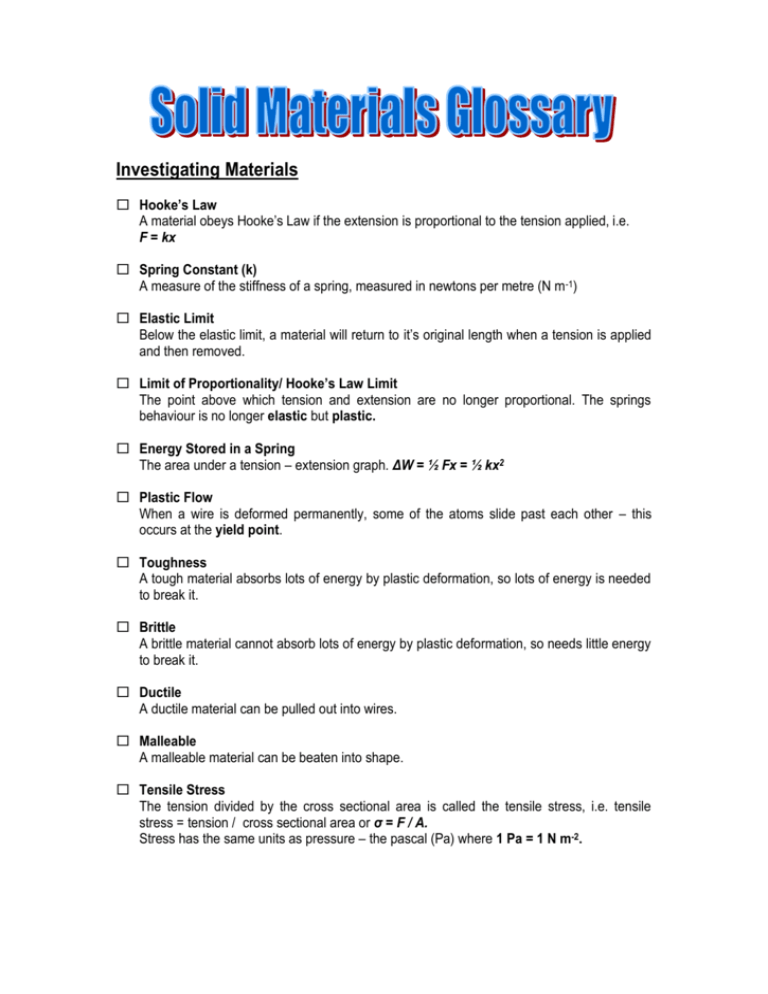

Investigating Materials Hooke’s Law A material obeys Hooke’s Law if the extension is proportional to the tension applied, i.e. F = kx Spring Constant (k) A measure of the stiffness of a spring, measured in newtons per metre (N m-1) Elastic Limit Below the elastic limit, a material will return to it’s original length when a tension is applied and then removed. Limit of Proportionality/ Hooke’s Law Limit The point above which tension and extension are no longer proportional. The springs behaviour is no longer elastic but plastic. Energy Stored in a Spring The area under a tension – extension graph. ΔW = ½ Fx = ½ kx2 Plastic Flow When a wire is deformed permanently, some of the atoms slide past each other – this occurs at the yield point. Toughness A tough material absorbs lots of energy by plastic deformation, so lots of energy is needed to break it. Brittle A brittle material cannot absorb lots of energy by plastic deformation, so needs little energy to break it. Ductile A ductile material can be pulled out into wires. Malleable A malleable material can be beaten into shape. Tensile Stress The tension divided by the cross sectional area is called the tensile stress, i.e. tensile stress = tension / cross sectional area or σ = F / A. Stress has the same units as pressure – the pascal (Pa) where 1 Pa = 1 N m-2. Strain The strain of a material is the extension divided by the original length, i.e. strain = extension / original length or ε = x / l. Since extension and length have the same units, strain has no units. The Young Modulus The gradient of a stress – strain graph is the Young Modulus, i.e. Young Modulus = stress / strain or E = σ / ε. Young Modulus is a measure of the stiffness of a material (a stiff material has a high Young Modulus). The units of Young Modulus are Pa. Energy Density The energy density of a wire is the area under a stress – strain curve, i.e. the work done per unit volume of the wire. During elastic deformation, energy density = ½ x stress x strain. It also has the units N m-2 or Pa. Yielding The yield stress is the stress at which permanent deformation occurs – i.e. where dislocations begin to move. Fatigue A material can fail even though it is below it’s below the yield stress. Loading and unloading can produce tiny cracks that expand with time – this is called fatigue. Elastomers An elastomer is a material which returns to its original shape when a distorting force is removed, e.g. rubber. Hysteresis Ever time an elastomer is stretched and released it becomes hot because energy is absorbed. It then heats the surroundings. This is called a hysteresis loss.