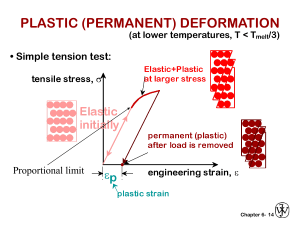

Property Definition Calculation Tests Use in design Relationship to other properties Relationship to Bonding Mechanical Properties that have to do with a reaction to an applied load Ductility The measure of the degree of plastic deformation at fracture Percent elongation %EL = (lf-lo/lo)x100 Percent reduction in area %RA = (A0-Af/A0) Tensile strength test Used in manufacturing to know what materials can be machined in specific ways, and used in buildings when complete failure would have devastating results (think plastic deformation during earthquakes) Brittleness: lack of ductility Metallic bonding provides the best ductility Modulus of elasticity Quantifies a material's resistance to elastic deformation E = stress/strain in the elastic region of a stress-strain curve Tensile strength test Used to determine how much a material will deform under a certain load The higher the E the higher the stiffness. Higher interatomic bonding, higher E value Yield Strength (tension) The stress at which noticeable plastic deformation starts to occur. The intersection of 0.2 offset and a line drawn parallel to the slope (E) of a stress-strain curve Tensile strength test Used to determine the max load that will produce only elastic deformation Used to determine Resilience Ultimate Tensile Strength The max stress that occurs during plastic deformation The highest point on a stress-strain curve Tensile strength test Used when working with brittle materials as they have no yield point Used to determine the toughness Poisson’s Ratio A ratio of deformation of the width of a material and the length v = -(εxx/εzz) Tensile strength test Used to determine stress and For isotropic materials deflection properties of materials 𝐺 = 𝐸 2(1+𝑣) The capacity of a material to The area under the Resilience 𝐾= Tensile strength Resilient materials have high 𝐸 3(1−2𝑣) Modulus of resilience Stronger bonds lead to lower poission ratios absorb energy when deformed elasticity, and then, upon loading, to have this energy recover stress-strain curve up to yield strain Materials resistance to fracture when a crack (stress-concentrating defect) is present. (fracture toughness) Or Ability of a material to absorb energy and plastically deform before fracturing. (notch toughness) Area under the stress-strain graph up until fracture Hardness Materials resistance to localized plastic deformation Thermal Properties Properties related to change in temperature in and across materials Heat Capacity Thermal Shock resistance Toughness test yield stress and low modulus of elasticity and are good for springs Uf Tensile strength test Used becasue it is almost impossible and costly to manufacture a piece without defects Metals: must display both strength and ductility Through test -Rockwell Hardness test - Brinell Hardness test -Knoop and Vickers Microindentation Hardness test Easy and inexplensive, tests are non-destructive, and other properties can be estimated Tensile strength TS(MPa) = 3.45xHB TS(psi) = 500xHB The ability of a material to absorb heat from it’s surroundings Through tests Calorimetry Used to select materials for temperature control of environments Specific heat The ability of a material to resist fraction when exposed to extreme temperature changes Based on other material properties Thermal shock resistance test Used when selecting materials for use in extreme environment Thermal Conductivity ε𝑦 Ur = ∫ σ𝑑ε 0 ε𝑏 𝑡𝑜𝑢𝑔ℎ𝑛𝑒𝑠𝑠 = ∫ σ𝑑ε 0 Stronger bonds produce higher hardness Higher in metallic bonding Thermal Conductivity The ease of which energy can move through a material Based on material constants and geometry N/A Needed for determining conductive materials Electrical conductivity is the same in metals Needs a see of electrons to be high