Presentation Slides

advertisement

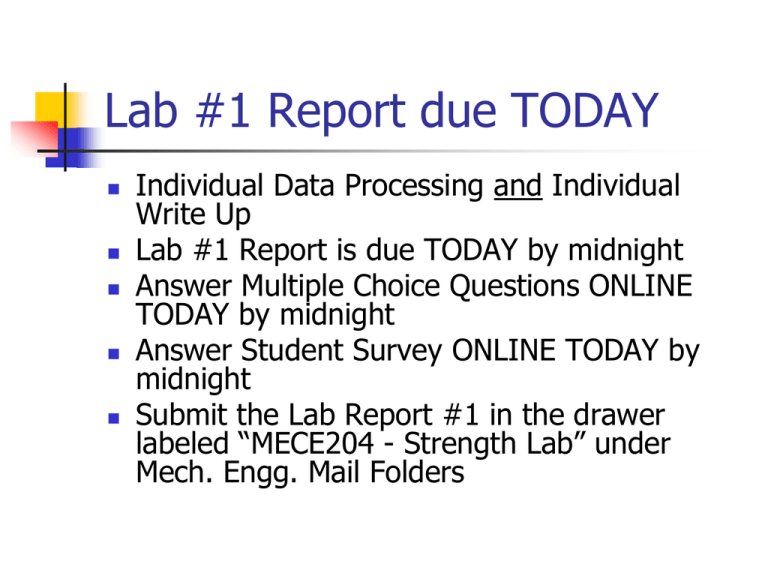

Lab #1 Report due TODAY Individual Data Processing and Individual Write Up Lab #1 Report is due TODAY by midnight Answer Multiple Choice Questions ONLINE TODAY by midnight Answer Student Survey ONLINE TODAY by midnight Submit the Lab Report #1 in the drawer labeled “MECE204 - Strength Lab” under Mech. Engg. Mail Folders Tensile Testing: Objectives Learn elastic and plastic behavior of metallic materials in monotonic tension Learn the use of Tinius Olsen 120 kips UTS and clip-on extensometer Conduct tensile testing experiment on 1018 steel and 2024 aluminum alloy Determine quantitatively elastic and tensile mechanical properties Determine qualitatively the material’s failure mode Become familiar with ASTM E-8 Standard Submit a professional lab report with abstract, data, graphs, and discussion Answer multiple-choice questions and student survey ONLINE using MyCourses Tensile Properties Quantitative determination of Elastic Modulus, E Proportional Limit, PL 0.2% Offset Yield Strength, Y Tensile Strength, TS % Elongation to Failure, %f Modulus of Toughness, Atotal Qualitative study of Failure Stress and Strain P P B (a) Tension-Test Specimen r P B F (b) Cross-Section at B F A L Figure 1.1 Tension-test Specimen (a) Axially Loaded and (b) Cross-Section at B Engineering Stress-Strain Curve Non-uniform Plastic Deformation Uniform Plastic Deformation Elastic Deformation , psi u f y Yield Regio n Elastic Regio n Plastic Regio n , in/in Figure 1.3 Stress-Strain Diagram, Labeled Actual Experimentation 0.2% Offset Yield Strength Modulus of Resilience Modulus of Toughness Necking begins at maxima Shape of Necked Region Engineering vs. True StressStrain Engineering Stress = e = P / A0 True Stress = t = P / Ai Engineering Strain = e = / L0 = (Li – L0) / L0 implies Li = L0 * (1 + e) Assume volume is constant until necking: A0*L0 = Ai*Li Ai = A0/(1+e) True Stress = t = P / Ai = P (1 + e) / A0 = e (1 + e) True Strain = t = (dL)/L = Ln(Li / L0) = Ln (1 + e) Comparison Ductile vs. Brittle Failure Fracture Surfaces Testing Equipment Universal Testing Machine (UTM) Monotonic Static Tension Test Single direction, Load increased slowly Crosshead Motion Tension, Compression and Flexure Motor-driven Screw Hydraulically-driven Crosshead ASTM Standards: E8 Testing Methods Displacement Control Load Control Open loop, Most Common Close Loop Feedback, Expensive Strain Control Close Loop Feedback, Expensive Data Sheet Data Sheet (continued) Demonstration Perform the tensile testing experiment on 1018 Cold Rolled Steel Data Sheet (continued) Lab #1 Report due TODAY Individual Data Processing and Individual Write Up Lab #1 Report is due TODAY by midnight Answer Multiple Choice Questions ONLINE TODAY by midnight Answer Student Survey ONLINE TODAY by midnight Submit the Lab Report #1 in the drawer labeled “MECE204 - Strength Lab” under Mech. Engg. Mail Folders