课件1

advertisement

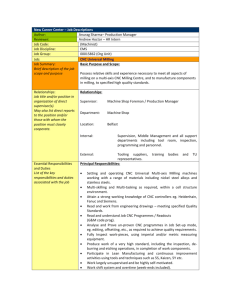

Unit 1: Introduction to Numerical Control 1.1 History of Numerical Control 1.2 Concept of NC and CNC 1.3 Basic Components of NC Machine Tools 1.4 Classification of NC Machine Tools 1.5 NC Features and Applications NC and CNC NC: Numerical Control ↓ ( 1970's ) 1.1 History of NC ( 数控 ) (1) Concept for NC → 1940s United States Air Force and aerospace industry (complex parts: manual machining + inspected by templates ∣ manual methods ) ↓↓ time consuming and inaccurate John Parsons: inspection templates for helicopter rotor blades Parsons' method: calculating the coordinate points (intermediate points ) ︱ manually moving to each of these points ↓ accuracy of templates improved idea : punched cards for the many calculations ↘ Punched card (穿孔卡) data used to position the machine tool first attempts: (automatic position control) punch card tabulating machines (to calculate the positions) + manual milling machine (to position the tool ) ( two operators, one to move each axis ) ↓ tens of times more accurate still time-consuming punch card tabulating machine Parsons envisioned the following system: a computer (calculate the path) + punched cards (store information) + a reader ( read cards) + the machine control (control motors attached to each axis) • In 1952, a three-axis milling machine was demonstrated vacuum tube (电子管) electrical cabinet (电气控制柜) electrical relay (继电器) The first NC machine (2)Development of NC 1 generation: vacuum tube (电子管) (1952) +electrical relay (继电器) +machine control interface (接口) 2 generation: improved miniature electronic tubes (transistor) (1959) (晶体管) 3 generation: small scale integrated circuits(小规模集成电路) (1965) 4 generation: improved integrated circuits (大规模集成电路) (1970s) 1.2.3----hardwared NC: functions by hardwares 4…------computer used→CNC integrated circuits ROM improved integrated circuit ------microprocessor (1980s) (machines are strengthened with advances:) Part program memory storage (零件程序存储); Reduction of printed circuits boards (印刷电路板) Programmable interface (可编程接口) Faster memory access (快速程序存取) Parametric subroutines (参数化子程序) Macro capabilities (virtually: 固定循环) microprocessor Since the 1980s, no hardwired NCs have been produced. Today, when the term NC is mentioned, it normally means CNC 1.2 Concept of NC and CNC (1) NC: a form of programmable automation in which the mechanical actions of a machine tool or other equipment are controlled by a program containing coded alphanumeric data (字母数字信息). • alphanumeric data: relative positions between a workhead (加工部分,工作头) and a workpart(工件) + instructions needed to operate the machine suitable for low and medium production (2) CNC: A CNC machine: an NC machine + an on-board computer ↓ machine control unit or MCU ★ NC and CNC NC: hard wired ( machine functions by physical electronic elements) CNC: ‘soft’ wired ( machine functions are encoded into the computer ) more flexible than NC: a memory, calculations, decisions detect problems, communicate with operator and external devices Part drawing Part program Control computer Servo-drive unit Machine tool Part 1.3 Basic Components of NC Machine Tools five fundamental units of typical NC machine tool • 1)the input media(输入介质); • 2)the machine control unit(机床控制单元); • 3)the servo-drive unit(伺服驱动单元); • 4)the feedback transducer (反馈传感) • 5)the mechanical machine tool unit (机床本体). 1) The input media: program of instructions(a part program) →direct actions Instructions: position commands + additional instructions The program is coded on a suitable medium for submission(传送) to the machine control unit. Types of medium :punched tape, magnetic tape, diskette, electronic transfer from computer. 2) machine control unit (MCU) : a microcomputer +related control hardware + system software, Function of MCU: stores program, Converts commands into mechanical actions, Executes program 3) servo-drive unit: drive motors + servo-amplifiers 4) feedback transducer(传感器): sensors measure actual position to minimize this difference. 5) the machine tool : performs useful work worktable and spindle 1.4 CLASSIFICATIONS OF NC MACHNINES NC machines are classified in different way: (1) the types of NC motion control system, (2) the type of servo-drive system, (3) application of NC. (1) Types of NC Motion Control System two types: point-to-point continuous path ﹡Point-to-Point Control Systems (Positioning Control Systems) move to a programmed location without regard for the path Movement from one point to the next is non-machining The rate of movement is usually maximum for the slide ﹡ Contouring Control Systems (continuous path control systems) To follow any path at any prescribed feed-rate To control two or more axes simultaneously to get desired shape (angular surfaces, two-dimensional curves, or three-dimensional contours) ▲parallel to one of major axes →straight-cut NC simultaneous control of two or more axes →contouring NC (2) Types of NC Servo-Drive Systems based on how the NC system accomplishes positioning, Three types of drives: open-loop(开环) drive system, closed-loop(闭环) drive system, half closed-loop(半闭环) drive system. ● Open-Loop Servo-Drive (开环伺服驱动) simplest and least cost form of servo-drive An open-loop control system Feature: lacks feedback ( no sensing device to confirm the action ) ↓ (反馈) actuator will not have the intended effect → (disadvantage ) motor : stepping motor (步进电机) advantages: high accuracy, easy implementation, compatible with digital signals; 1 2 3 4 disadvantages: low torque (转矩,扭矩), limited speed and risk of missed pulse under load(重载) application is restricted to smaller machines ∣ light duty machinery ( no problems of instability, no requirements of high precision) → economical NC system ●Half-Closed-Loop Servo-Drive(半闭环伺服驱动) one of the feedback control system A half-closed-loop control system Feature: indirect feedback(间接反馈) monitors the output of servomotor(伺服电机) ↓ a feedback sensor is attached to servomotor axis or lead-screw (measures the rotary angle of motor or leadscrew) ↓ Disadvantage: unable to sense backlash or lead-screw windup Advantage: convenient to adjust , a good stability motor : Servo motor (DC or AC) (直流或交流伺服电机) ●Closed-Loop Servo-Drive (闭环伺服驱动) feedback control system A closed-loop control system Feature: direct feedback(直接反馈) monitors the actual position of worktable ↓ A feedback sensor directly measures the position of worktable ↓ Advantage: more accurate Disadvantage: implementation costs higher motor : Servo motor (DC or AC) (直流或交流伺服电机) (3) Application of CNC applications divided into two categories: (A) machine tool applications (B) non-machine tool applications Machine tool applications are those usually associated with the metalworking industries. Non-machine tool applications comprise a diverse group of operations in other industries. (A) Machine Tool Applications (Machining : manufacturing process, in which the geometry of work is produced by removing excess material. four common types of machining operations: (1) turning (performed on a lathe), (2) drilling (on a drilling press), (3) milling (on a milling machine), (4) grinding (on a grinding machine). NC lathe: (horizontal or vertical ) two-axis continuous path control NC boring mill: (horizontal or vertical spindle) Operation: continuous path, two-axis control Boring is similar to turning, except that an internal cylinder is created instead of an external cylinder NC drill press: point-to-point control of workhead (spindle containing the drill bit) and two axis (X-Y) control of the worktable. NC milling machine: require continuous path control to perform straight cut or contouring operations NC grinding machine: intended for finishing treatment includes cylindrical-(外圆磨床), surface- (平面磨床), internal- (内圆磨床), spindle- (心轴磨床), thread- (螺纹磨床), gear- (齿轮磨床), tool-grinding machines (工具磨床) Tool grinding machine Machining center: multifunction NC machines with automatic tool changer and tool storage (自动换刀装置) (刀库) major advantages: Increased productivity and versatility (eliminates the need for a number of individual machine tools, ↓ thus reducing capital equipment and labor requirements Additional savings: materials handling, fixture costs, and floor space requirements throughput faster in-process inventory replaced by work at one machine Machining centers: vertical or horizontal Vertical : primarily for flat parts; mold and die work; Machining centers: vertical or horizontal Horizontal : for large, boxy, and heavy parts. • • • • • • • • • 1-数控柜 control cabinet 2-刀库 tool magazine 3-主轴箱 headstock 4-操作面板 operation panel 5-驱动电源 driving power supply 6-工作台 worktable 7-滑枕 ram 8-床身 machine bed 9-进給伺服电机feed servo motor 10-换刀机械手 tool change manipulator Pivot insertion tool changer (B) Non-Machine Tool Applications Punch presses for sheet metal hole punching (板金冲床) Presses for sheet metal bending(弯板机) Welding machine (焊机) Thermal cutting machine(热加工机) Tube bending machine(弯管机) 1.5 NC Features and Applications characteristics: (1) batch production in small or medium lot sizes; (2) repeat orders at random or periodic intervals; (3) complex part geometry; (4) Much metal needs to be removed from part; (5) many separate machining operations on the part (6) the part is expensive ↓ NC benefits and advantages (economic savings for the user company) Advantages and Disadvantages of NC Advantages: Greater accuracy and repeatability; More complex part geometries are possible ; Nonproductive time is reduced Lower scrap rates (废品率) Inspection requirements are reduced Engineering changes can be accommodated more gracefully Simpler fixtures are needed Shorter manufacturing lead times (订货至交货的时间) Reduced parts inventory (库存) Less floor space(房屋面积) required Operator skill-level requirements are reduced Disadvantages of NC : Higher investment cost Higher maintenance effort Part program Higher utilization of NC equipment