CNC Machining

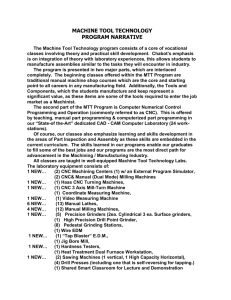

advertisement

CNC Machining MAE 165 Mohammed Albuali Kevin Hung John Shamblin CNC Overview • Computer Numerical Control machining is a subtractive method • 5 axes of control at most, 3 axes of control at the UC, Irvine CNC machine • Tolerance limits are determined by accuracy of x-y tables • CNC has the highest relative tolerances of any manufacturing method Preparing • Produce model of part using SolidWorks or AutoCAD, this is saved as a CAD file • Convert CAD file to CAM file • Put CAM file into CNC machine • Ensure that the x-y table is level and aligned Raw Material • For the demonstration: Al - 7”x7”x.25” • Determine dimensions of and mount work piece Calibration • Find x=0 and y=0 coordinates a corner of the work piece using the edge finder • Find relative height of each tool using the dial indicator and input measurement into CNC machine Tool List • Select tools and place in collets • Arrange tool in order to be used Machining • Run CAM file on the CNC machine • Change tools when prompted • Use jets and lubricants were needed to cool work piece Finishing Piece • Perform tertiary operations after removing from CNC machine • Clean off lubricants • Clean up lab