New Career Center * Job Descriptions

advertisement

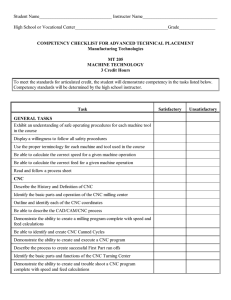

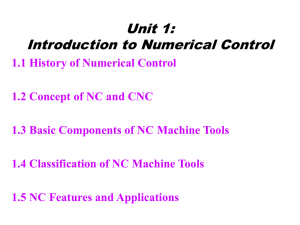

New Career Center – Job Descriptions Author: Anurag Sharma– Production Manager Reviewer: Andrew Hoctor – HR Intern Job Code: (Machinist) Job Discipline: EMS Job Group: 00015862 (Org Unit) Job: CNC Universal Milling Job Summary: Basic Purpose and Scope: Brief description of the job scope and purpose Possess relative skills and experience necessary to meet all aspects of milling on a multi-axis CNC Milling Centre, and to manufacture components in milling, to specified high quality standards. Relationships: Job title and/or position in organization of direct supervisor(s). May also list direct reports to the position and/or those with whom the position must closely cooperate. Essential Responsibilities and Duties List of the key responsibilities and duties associated with the job Relationships: Supervisor: Machine Shop Foreman / Production Manager Department: Machine Shop Location: Belfast Internal: Supervision, Middle Management and all support departments including tool room, inspection, programming and personnel. External: training Tooling suppliers, representatives. Principal Responsibilities: bodies and TU Setting and operating CNC Universal Multi-axis Milling machines working with a range of materials including nickel steel alloys and stainless steels. Multi-skilling and Multi-tasking as required, within a cell structure environment. Attain a strong working knowledge of CNC controllers eg. Heidenhain, Fanuc and Siemens. Read and work from engineering drawings – meeting specified Quality Standards. Read and understand Job CNC Programmes / Readouts (G&M code prog). Analyse and Prove un-proven CNC programmes in Job Set-up mode, eg. editing, offsetting, etc., as required to achieve quality requirements. Fully Inspect work-pieces, using imperial and/or metric measuring equipment. Produce work of a very high standard, including the inspection, deburring and etching operations, in completion of work components. Participate in Lean Manufacturing and continuous improvement activities using tools and techniques such as 5S, Kaizen, 5Y etc. Work largely unsupervised and be highly self-motivated. Work shift system and overtime (week-ends included). Previous Experience and Competencies: Experience/Education Required: e.g. BEng Electrical Engineering e.g. 2-3 yrs directional drilling experience in deep water environments Required Competencies (special knowledge and skills) Competencies to be kept current: Behavior: e.g. communicates effectively, learns quickly, adapts to new problems and situations Be Flexible in working requirements as the needs of the business dictate. Operate overhead and pillar type cranes/Lifting equipment. Comply with all Schlumberger QHSE Policies and procedures. Education: Fully recognised Apprenticeship in Manufacturing Engineering to minimum City & Guilds level 3 or equivalent. Experience: Significant and recent work experience in the setting and operating of CNC Universal Multi-axis Milling machines. Proven experience working in a precision engineering environment, producing components in stainless and nickel steel alloys from both fixed and rotary work tables on CNC universal milling machines, preferably within the oil and gas industry. Strong working knowledge and experience with machine controllers such as Heidenhain, Fanuc, and Seimens. Advanced working knowledge of G & M code programming, with experience in program editing and tool offsetting in component set-ups and work-piece prove-outs, with minimal support and supervision. Strong working knowledge of engineering drawings, manufacturing methods, tooling and fixturing in production. Practical experience in Lean manufacturing, with tools and techniques such as 5S, Kaizen, 5Y, etc. Multi skilled in machining operations (mill/turn); with experience of working more than one machine at a time and multi-tasking, in a cell structure. Skills: All skilled stated above within “experience”. Behaviour: Positive proactive attitude to work Learns quickly Adapts to new situations Communicates effectively Attention to detail Physical Demands: Ability to work a 3 shift rotating system. Travel Occasional travel as required to other plants and courses which the job and business dictates.