Chapter 13 X-ray tubes

advertisement

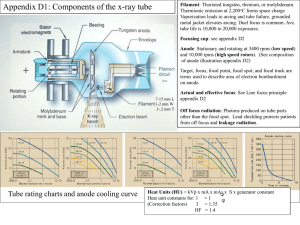

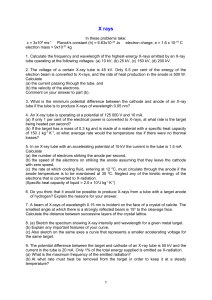

The X-Ray Tube Consists of: 1) Glass Envelope 2) Cathode 3) Anode 4) Surrounded by oil to cool tube (Contained in protective housing) Cathode Consists of Three Sub-Assemblies: 1) Filament 2) Support wires 3) Focusing cup Filament • Tungsten wire • 3-5 A, 10 – 12 V applied • Produces space charge through thermionic emission • Double focus tubes have 2 filaments to produce large and small focal spots • Filament problems include: 1) filament evaporation over time - Progressively less current is needed to achieve desired mA as this occurs - may lead to tungsten on envelope & “arching of the tube” Double focus filaments 2) filament breakage inside focusing cup Focusing Cup • Negatively charged • Used to focus electrons Filaments inside the focusing cup Three Support Wires • Delivers voltage and amperage to filaments • Wiring – Lines 1 and 3 – large filament lights Lines 2 and 3 – small filament lights Line 3 common to both filaments – produces high negative potential Anode May be: 1) Stationary – Used in dentistry, embedded in Cu 2) Rotating Anodes are composed of: 1) tungsten – Primary metal because it has: - has high melting point - high atomic no. (74) enhances diagnostic - high ability to dissipate heat 2) rhenium – Increases elasticity of focal track 3) graphite and molybdenum may also be added to increase heat dissipation Stationary Anode Rotating Anode Anode Focal Spots Actual Vs Effective (Apparent) Actual Focal Spot – The area on the anode hit by the bombarding electron stream - Approximately 2 X 6 Effective (Apparent) Focal Spot – The focal spot that is projected towards the image receptor. - Smaller effective focal spots yield improved spatial resolution - Approximate range from .1 mm - .6 mm Line Focus Principle – The effective focal spot is smaller then the actual focal spot. - Due to angle of anode - Always true with anodes less than 45° Anodes Key Facts to Remember • The size of the effective focal spot decreases as the angle of the anode decreases (becomes steeper) Advantages/Disadvantages of Steep Anodes Advantages – 1) Better spatial resolution 2) Increased short exposure rating - Disadvantages 1) Cutoff at short SID’s Anodes Key Facts to Remember • Steeper (decreased angled) anodes accentuate the anode heel effect. - Anode Heel Effect – The x-ray intensity is greater at the cathode versus the anode end of the tube. - In addition this effect is more pronounced at short SID’s Rotating Anodes Benefit – Heavier exposures at shorter exposure times. Composition: • Tungsten – Primary ingredient • Coated with Rhenium – Increases elasticity of focal track, decreases roughness • Molybdenum/graphite added to dissipate heat • Cu added in rotor to dissipate heat • 3-5 inches in diameter • Angle range 10° - 17° (12° most common) • 3,600 – 10,000 rpm • Turned with induction motor operating on the principle of electromagnetic induction • Effective focal spot sizes of .6 mm (large), .1 mm - .3 mm (small) Anode Warm Up Procedure - Done to decrease possible damage to anode from heat. Typical Warm-Up Procedure 80 kVp X 100 mA X 1 sec 80 kVp X 100 mA X 2 sec 80 kVp X 100 mA X 3 Sec. Space Charge Compensation Space Charge Effect – The tendency to resist further emission of electrons during thermionic emission. - Occurs as a result of repelling effects of space charge around filament - Space charge has definite size that depends on: 1) Size of filament wire 2) Applied mA Space Charge Limited Region – When an increase in mA automatically occurs with an increased kVp Saturation Current – That point where an increase in kVp will not automatically increase mA Space Charge Compensator – A device in the filament circuit that automatically lowers filament current as kVp is increased - allows independent control of kVp & mA Factors Affecting Tube Life Over heating of the filament & anode Leads to: • Vaporized tungsten deposited on the glass envelope - May cause arcing (sparkover) in the tube which is most common cause of tube failure • Increased filtration • Overheating the filament may also cause thinning and eventual burnout (breaking) of the filament • Overheating in filament is minimized by filament booster Circuit - Limits filament current until exposure is made • Overheating the anode may lead to a cracked or pitted anode, damage to rotor bearings Anode Factors Affecting Tube Life Life of the anode and the ability to use high mAs and kVp is related to the ability of anode to accumulate, store and discharge heat. Extension of tube life involves paying attention to: 1) Tube rating chart - A chart indicating the maximum safe exposure time for any selected kVp/mA combination for a single exposure. - Assumes use of a cold anode 2) Anode Thermal Capacity – Amount of heat that can be safely accumulated by an anode. 3) Anode Cooling Curve – A chart that indicates the rate of heat dissipation from the anode over a specified time period. Tube Rating Chart Ignoring the tube rating chart may lead to: • Melted or cracked anode • Vaporized tungsten on glass envelope • Pitting of the focal track/damage to rotor bearings Reading the tube rating chart: •Exposures above and to the right of the slanted line are not ok. •Exposures below and to the left of the line are ok. Tube rating charts are effected by: • Type of rectification • Size of tube focus • Tube design • Cold Vs hot tube • Type of power supply • Application • Anode rotational speed Anode Thermal Capacity Thermal capacity is measured in heat units (HU). H.U. – single phase = kVp X mA X time 3 Phase, 6 pulse = kVp X mA X time X 1.35 3 phase, 6 pulse = kVp X mA X time X 1.41 high frequency = kVp X mA X time x 1.45 An increase in kVp and decrease in mAs (all other factors constant) will decrease heat units. Typical thermal capacity (general diagnostic tube) 70,000 – 400,000 H.U. (angiography, CT tubes have much higher capacities) Increasing mass, surface area or rotational speeds of the anode will increase thermal capacity & short exposure ratings. Pitting – Occurs due to repeated minor overloading Cracking – Occurs due to overloading a cold tube Tube Housing Factors Effecting Thermal Dissipation Thermal dissipation – Cooling that results from the transfer of heat to: 1) Oil (surrounds glass envelope) - some tubes equipped with forced oil systems 2) Tube Housing 3) Housing Fan – dissipates heat from tube housing Practical Steps in Extending Tube Life • Decrease boost and hold time - Extends filament & bearings life - Decreases tungsten deposits on glass envelope • Never exceed instantaneous tube ratings - Avoids cracked or pitted anode • Use the correct tube rating and cooling charts • Use an anode warm-up procedure - Avoids cracked anode • Follow exposure rating charts and anode cooling charts to extend filament and anode life span