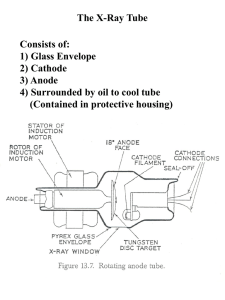

4. The X-Ray Tube

advertisement

The X-Ray Tube DMI 50B Kyle Thornton Evolution Of The X-Ray Tube Roentgen experimented with a Crookes tube – – In 1913, W.D. Coolidge redesigned the tube, calling it a hot cathode tube – – Evacuated tube containing two electrodes Could not control the number of electrons moving between the electrons (tube current) Replaced the negative electrode with a small spiral-wound tungsten wire Current was applied to this wire creating heat to free electrons Hot cathode tubes became the standard for x-ray tubes Cold Cathode X-Ray Tube Early 20th century Cold Cathode Tube Fluorescence Coolidge Tube w/Stationary Anode Helpful website http://www.ndted.org/EducationResources/HighSchool/Radio graphy/xraygenerators.htm http://www.youtube.com/watch?v=Bc0eOjWkxp U Common Components Of The XRay Tube Glass envelope Cathode Anode Glass Envelope A vacuum is created prior to sealing the tube The glass envelope: – Provides support for the electrodes – Provides electrical insulation – Assists in the removal of heat – Is made of very thick glass to withstand heat – Is thinner at the exit window where the x-rays emerge from the tube Cathode Negative electrode of the x-ray tube Consists of a filament and a focusing cup The filament provides a source of electrons Electrons are freed when the filament is heated The filament is a long thin tungsten wire shaped into a spiral coil Cathode About 10 volts and 3 – 5 amperes are applied to the filament to heat it Tungsten is used because of its high melting point 3370° C It is also malleable Most modern tubes contain two filaments – – The longer filament is used when large numbers of electrons are needed The shorter filament is used when lower tube currents and maximum detail are needed The Focusing Cup The filaments are mounted within a focusing cup Generally made of nickel, stainless steel, or molybdenum A negative charge is placed on the focusing cup Focuses the electrons on a smaller spot of the anode This improves detail on the film Benefit of the Focusing Cup X-Ray Tube Focusing Cup http://www.youtube.com/watch?v=LyWuvSZRSLc &feature=related The Anode The anode is the positive electrode It is struck by the electron stream The area struck is the anode target Usually made of tungsten A great deal of heat is produced at the anode – Depends on the voltage, the current, and the length of time the anode is struck by electrons Stationary Anodes Used when lower heat quantities are produced Consists of a tungsten target and copper block and stem Copper conducts the heat away from the tungsten target The heat can damage the anode target, causing pitting – Results in x-ray beam of reduced intensity due to scattering and absorption in the uneven surface Rotating Anodes The first was made by Philips Medical Systems in Holland in 1929 Consists of a tungsten alloy disk on a molybdenum base Rotating anodes range in size from about 5 cm to 12.5 cm Disk sizes determine the thermal load Anodes have an angle of about 7° to 20° Rotating Anodes Rotating anodes assure that the same area of the target being struck over and over is rare Heat energy is distributed more evenly over the anode face More rapid exposures are possible The rotating anode is driven by an induction motor Purposes Of The Anode Serves as a positive electrode Provides structural support for the target plate Provides a means for of dissipating heat to the target The Benefits Of Using Tungsten As A Target Material Malleability High melting point 3370° C High Z number Resists vaporization at high temperatures Ability to conduct heat away from area of heat production Its density Ability to absorb heat without raising the temperature of the conductor Its availability makes it cost-effective The Induction Motor Works on the principle of Lenz’ law Using opposing magnetic fields, the copper bar is made to rotate Rotation of the anode is accomplished more efficiently this way The anode is surrounded by electromagnets that are switched on and off in rapid sequence Anodes utilize 60 Hz AC Anodes usually rotate at 3600 rpm – Newer anodes may rotate at 10,000 rpm Induction Motor Diagram Target Plate Angulation The area of the target struck by the electron stream is the focal spot Image sharpness is improved when the focal spot is small By angling the target, a small area can be struck, but at the same time provides a large space for heat dissipation Line-Focus Principle By angling the target, the effective area is much smaller than the actual area of electron interaction As the target angle decreases, so does the effective focal spot Dual Focus Anodes Heel Effect A consequence of the line focus principle The beam intensity on the cathode side is more intense than on the anode side Patients must be positioned accordingly for some exams Heel Effect Off-Focus Radiation Off-Focus Radiation Radiation produced when electrons bounce off the target area of the anode and strike other areas and produce x-rays About 15% of the electrons do this This reduces image contrast Can be controlled by applying an additional diaphragm close to the focal spot Tube Exit Window The useful beam is emitted from the tube exit window This section of glass is generally much thinner than the rest of the tube The Tube Housing Supports and houses the x-ray tube Provides insulation Prevents shock Is lined with a lead tube shield to prevent leakage radiation Oil surrounds the tube within the tube shielding The Tube Housing Causes Of X-Ray Tube Failure A single excessive exposure Long exposure times Filament vaporization – The most common Safe Operation With Tube Rating Charts Radiographic rating chart Anode cooling chart Housing cooling chart Tube Rating Charts Here’s Some Questions Which of the following exposures are unsafe? – – – – – 95 kVp, 150 mA, 1 sec. 3400 rpm, .6mm focal spot 80kVp, 400 mA, .5 sec. 3400 rpm, 1mm focal spot 125 kVp, 500 mA, .1 sec 10,000 rpm 1 mm 75 kVp, 700 mA, .3 sec, 10,000 rpm 1 mm focal spot 88 kVp, 400 mA, .1 sec., 10,000 rpm .6mm focal spot Heat Units The product of mA, T, and kVp HU = mA X T X kVp Used to determine thermal capacity of an anode or tube housing The tube housing cooling chart is similar to that of the anode cooling chart Anode Cooling Chart Here’s Some More Questions If 50,000 HU are delivered to the anode, how long will it take to cool completely? How many heat units are produced if 6 films are exposed using a three phase, six pulse generator at 82 kVp and 120 mAs