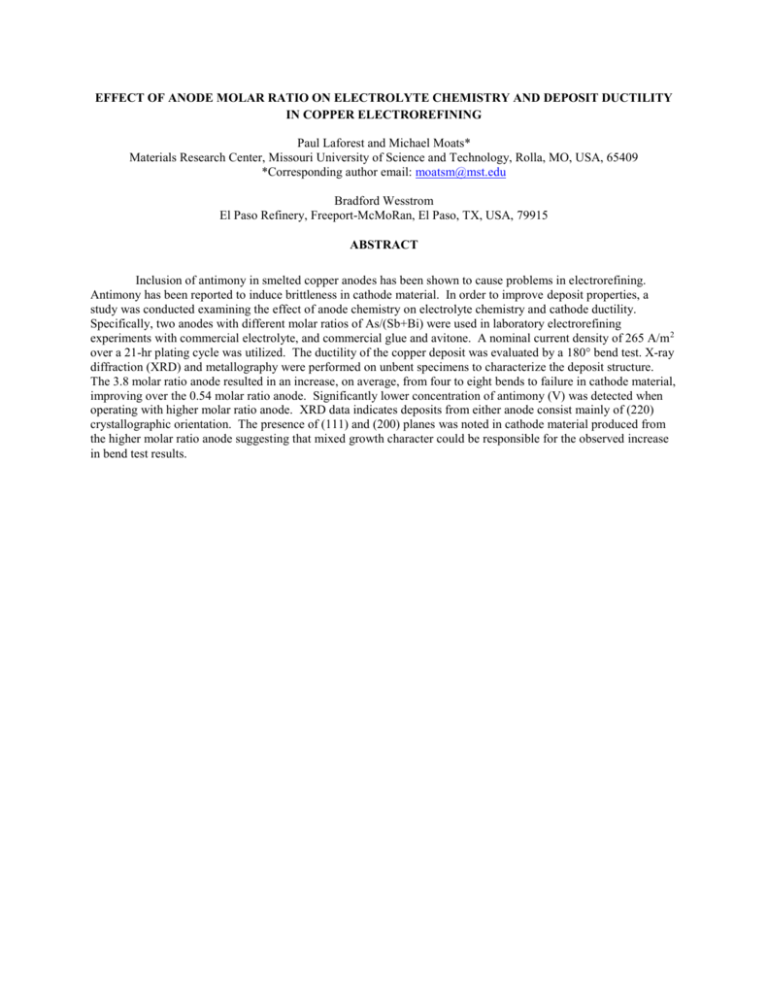

Anode Ratio Effect on Copper Electrorefining Ductility

advertisement

EFFECT OF ANODE MOLAR RATIO ON ELECTROLYTE CHEMISTRY AND DEPOSIT DUCTILITY IN COPPER ELECTROREFINING Paul Laforest and Michael Moats* Materials Research Center, Missouri University of Science and Technology, Rolla, MO, USA, 65409 *Corresponding author email: moatsm@mst.edu Bradford Wesstrom El Paso Refinery, Freeport-McMoRan, El Paso, TX, USA, 79915 ABSTRACT Inclusion of antimony in smelted copper anodes has been shown to cause problems in electrorefining. Antimony has been reported to induce brittleness in cathode material. In order to improve deposit properties, a study was conducted examining the effect of anode chemistry on electrolyte chemistry and cathode ductility. Specifically, two anodes with different molar ratios of As/(Sb+Bi) were used in laboratory electrorefining experiments with commercial electrolyte, and commercial glue and avitone. A nominal current density of 265 A/m 2 over a 21-hr plating cycle was utilized. The ductility of the copper deposit was evaluated by a 180° bend test. X-ray diffraction (XRD) and metallography were performed on unbent specimens to characterize the deposit structure. The 3.8 molar ratio anode resulted in an increase, on average, from four to eight bends to failure in cathode material, improving over the 0.54 molar ratio anode. Significantly lower concentration of antimony (V) was detected when operating with higher molar ratio anode. XRD data indicates deposits from either anode consist mainly of (220) crystallographic orientation. The presence of (111) and (200) planes was noted in cathode material produced from the higher molar ratio anode suggesting that mixed growth character could be responsible for the observed increase in bend test results.