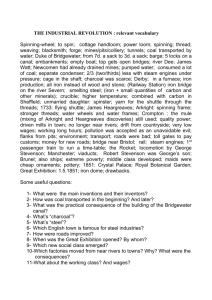

Weber's Least Cost Theory

advertisement

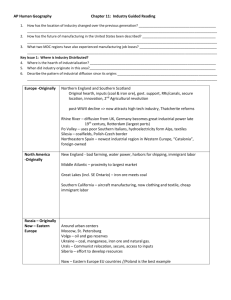

Industry & Services De Blij Chapter 12 Pre Industrialization • Cottage Industry & Guilds- products made at home India’s textiles being made in homes on handlooms and spinning wheels. Preindustrial World • The industrial Revolution accelerated development, but it did not begin with it • Modern age is better classified as Industrial Intensification! Where did the Industrial Revolution begin? • The Industrial Revolution originated in areas of northern England in the late eighteenth century. • Factories often clustered near coalfields. • Densely populated regions called “Black Country” b/c of this • Why Great Britain? – Flow of capital – Second agricultural revolution – Mercantilism and cottage industries – Resources: coal, iron ore, and water power Britain • 1st to industrialize gave them what we call: • Comparative Advantage – the ability to produce something more efficiently than any other – Ex: able to manufacture products faster and cheaper since they were the only ones with machines • As opposed to an Absolute Advantage- when a region has more of a resource than any other area – Ex: Saudia Arabia has more oil than any other country, so they have the Absolute Advantage over Oil Flow of Capital into Europe, 1775 Industrial Revolution – Inventions lead to the use of machines and inanimate power in the manufacturing process – Suddenly whole societies could engage in seemingly limitless multiplication of goods and services – Rapid bursts of human inventiveness followed – Gigantic population increases 2 main industries diffused with the industrial revolution: Iron • Iron ore is mined - ore is melted (smelted) - pour iron into molds that can be transported - now called Pig Iron • Pig iron is shipped to be remelted into something useful • Could be used to make steel with addition of Coal • Coal - bulky so factories located near the coal and iron ore mines • Transportation took on a new meaning - canals and railways were built to transport: people, products and raw materials Textiles • Spinning yarn - turns the short threads from cotton plants into continuous yarn needed to weave cloth. Carding is the untwisting of the fibers prior to spinning. • A lot of energy was needed more than humans could supply - along comes the Steam Engine • All processes to make cloth could now be housed in one building - The Factory Innovations of the Industrial Watt Steam Engine Revolution Water Pumps for Mines • Machines were water powered (steam) which brought in new uses for coal as an energy source. • James Watt & Mathew Boulton invented the steam engine Power Loom Locomotives Innovations • Abraham Darby (1709) created the process to smelt iron. • Mixing the iron ore with limestone and water and smelting it with coke enabled iron workers to pout it in molds creating cast iron. Ironbridge, England World’s first cast iron bridge 1799 The first rail lines connected Manchester, a center for textile manufacturing, to Liverpool, a west facing port to the colonies. Steam powered ships would carry the textiles to distant markets. • Textiles Production: – Liverpool and Manchester • Iron Production: – Birmingham • Coal Mining: – Newcastle Diffusion to Mainland Europe Same set of locational criteria for industrial zones applied: 1) proximity to coal fields & 2) connection via water to a port 3) large urban markets for purchasing goods Diffusion of Industry Around the World Diffusion to the Northern European Lowlands Map of Rotterdam – the most important port in Europe & a hub of global commerce • Northern France, Southern Belgium, the Netherlands, the German Ruhr, western Bohemia in the Czech Republic, and Silesia in Poland along a belt of iron ore deposits. • Rotterdam, Netherlands, became a major port at the mouth of the Rhine River. Why did Europe have Industrial Success? • Availability of Raw Materials • Colonialism brought in materials from around the world • Skilled labor force • Specialization of major industries • Trading products • Trading routes The Location Decision. . . • Primary Industries- must locate next to resources • Secondary- less dependent on location – Can transport raw materials if profit outweighs cost How Do Location Theories Explain Industrial Location? • Improvements to • LOCATION THEORIES transportation & predict where businesses communication created a will or should be located. time-space compression – Assumptions: • Decision makers are trying making secondary to maximize their industries less dependent advantage over on resource location. competition • They want to make as • Raw materials can be much profit as possible transported to distant • They will take into account locations to be converted variable costs TRANSPORTATION into manufactured FRICTION LABOR products. OF DISTANCE ENERGY Variable Costs • Additional costs due to: – Energy, Labor, Transportation • Companies try to minimize these costs because of: • Friction of Distance- increase in time and cost with increasing distance of production (serving markets further away) • Distance Decay- impact of a function or activity will decline as one moves away from point of origin – Says that manufacturing plants will serve close markets – Variable costs will go up as you serve markets further away Factors of Industrial Location Raw Materials • Very few industries use raw materials • Most manufacturing is based on the further processing and shaping of materials already treated in some fashion • Transportation costs affect industry location Factors of Industrial Location • Power Supply (Energy) – Power supplies that are immobile or of low transferability may attract activities dependent on them – Current technology made less important – Industries requiring large amounts of energy still situated near the power source Factors of Industrial Location • Labor – Spatial variable affecting location decisions and industrial development – 3 major traditional considerations • price, skill, and amount – Labor Flexibility: highly educated workers able to apply themselves to a wide variety of tasks and functions Factors of Industrial Location • Market – Goods are produced to supply a market demand – Size, nature, and distribution or markets is important in industrial location decisions – Ubiquitous industries • Transportation – Unifying thread of all factors of industrial location – Modern industry is immediately tied to transportation – Use many different form of transportation media Alfred Weber’s Least Cost Theory • Created the classical model of industrial location theory in 1909 • Explains the optimum location of a manufacturing establishment in terms of the owner’s desire to minimize three basic expenses – Transportation cost, labor, agglomeration (rent) Weber’s Least Cost Theory Expenses to Minimize 1. Transportation: the site chosen must entail the lowest possible cost of a) moving raw materials to the factory b) finished products to the market. This, according to Weber, is the most important. Weber’s Least Cost Theory Expenses to Minimizes 2. Labor: higher labor costs reduce profits, so a factory might do better farther from raw materials and markets if cheap labor is available • -ex: China – today Weber’s Least Cost Theory Expenses to Minimize 3. Agglomeration (rent): when a large number of enterprises cluster in the same area, they can provide assistance to each other through shared talents, services, and facilities -ex: manufacturing plants need office furniture Agglomeration Continued • Too many enterprises clustering together can INCREASE the cost of rent, wages, etc • This has caused some industries to actually LEAVE urban areas – deglomeration. Weber’s Least Cost Theory 5 Controlling Assumptions 1. Area is uniform physically, culturally, and technologically 2. Manufacturing involves a single product to be shipped to a single market whose location is known 3. Inputs involve raw materials from more than one known source location 4. Labor is infinitely available but immobile in location 5. Transportation routes connect origin and destination by the shortest path and directly reflect the weight of the items shipped and distance moved Weber’s Least Cost Theory Transport costs: One market and two sources: • Equal distance and shipping costs dictates a market location • Two weight-losing materials results in an intermediate location Weber’s Least Cost Theory Labor Costs: Location chosen always has least combined costs • A location may have higher transport costs, but less expensive labor Weber’s Least Cost Theory Agglomeration: Weber recognized that clustering will result in a per unit savings • Shared benefits • • • • • Facilities Labor force Infrastructure Services Raw materials Weber’s Least Cost Theory Limitations of the Theory: • There are geographic variations in market demand • There are terminal costs (payments at break of bulk points – taxes/tariffs) • Transport costs are becoming less of a factor • Labor is mobile and does not exist in unlimited quantities • Plants often produce a variety of outputs for many markets Weber’s Least Cost Theory Additional Contemporary Considerations • • • • • • Access to capital Access to technology Friendly regulatory environment Political stability Land cost Inertia Substitution Principle • This is the tendency to substitute one factor of production for another to achieve optimum plant location and profit – Must weigh all factors to determine the best, profitable location • Ex: you will pay more for transportation costs if you can save more on labor costs for overall production costs (Using China) Hotelling’s Model • Locational Interdependence- Model seeks to answer question of where like businesses will locate – Ex: why do we see McDonalds right beside Wendy’s, Burger King, and Sonic??? • Basically, why do businesses that sell the same thing locate right beside one another? • Hotelling used ice cream vendors on a beach as an example. Hotelling’s Model of Locational Interdependence • Location of an industry cannot be understood without reference to other industries of the same kind. Theory: • Locational interdependence: • indicates that locational decisions are not made independently but are influenced by the actions of others. Hotellings, cont. • Model says: – – – – Start at locations far away from one another Want to MAXIMIZE sales Constrain the other’s territory to bring sales up Causes them to move closer together until they are back to back • Model Shows: – Industry location can’t be understood without looking at other like industries • Downsides – Only variable is wanting to maximize sales – Cost for customers is greatest at center of beach • They have to walk further from end of beach, so they may not come Losch’s Model – Zone of Profitability • Manufacturing plants choose locations where they can maximize profit. • He added the spatial influence of consumer demand and production costs to his calculations. To the left and right of the zone, distance decay will make sales unprofitable. Major Industrial Regions of the World Before 1950 Four Primary Industrial Regions: 1) Western & Central Europe 3) Russia & Ukraine 2) Eastern North America 4) Eastern Asia Western and Central Europe Late 18th Century: Britain France Belgium Netherlands Germany: 3 districts? (the Ruhr, Saxony, & Silesia) Early 20th Century: Italy: What area? Spain: What area? Sweden Finland Manufacturing Centers in Western Europe Fig. 11-6: The major manufacturing centers in Western Europe extend in a north-south band from Britain to Italy. Manufacturing Belts of Germany (3): The Ruhr – based on the Westphalian coal field; known for high-quality resources, good accessibility, and proximity to large markets Saxony – (near former Czechoslovakia) known for light manufacturing such as optical equipment, cameras, refined textiles, and ceramics. Silesia - (now apart of Poland)based on highquality coal reserves & iron ore Major Manufacturing Regions of North America Light Industry Chemical industries Heavy Industry -Benefitted from overseas resources -Large coal and gas reserves to provide energy to manufacturing plants -US capitalized on industry after Western Europe destruction during WWI and WWII American Manufacturing Belt • Extends from the northeast to Iowa, and from the St. Lawrence Valley to the Ohio and Mississippi rivers. • New York port serves as a major break-of-bulk point, where cargo is transported from one mode of transportation (truck/train). Generates employment, activity, & wealth. • Erie Canal dug to connect east coast to Great Lakes Industrial Regions of North America Wide Range of Manufacturing includes: Steel Mills Chemical Industries Electrical Appliances Auto Industry Erie Canal was dug to connect east coast to the Great Lakes Fig. 11-4: The major industrial regions of North America are clustered in the northeast U.S. and southeastern Canada, although there are other important centers. Other North American Regions 1. Southeastern district – iron, cotton, tobacco 2. Southwestern district – meatpacking, flour mills 3. Western district – this area has grown due to increased trade with Asia (part of the Pacific Rim) Manufacturing Value Change Fig. 11-5: The value and growth of manufacturing in major metropolitan areas in the U.S. between 1972 and 1997. Agglomeration - note how the parts plants locate near the assembly plants. Former Soviet Union • Ukraine (western region of the USSR) helped make the USSR and industrial power • Developed industry in: – Moscow – large market & labor force – Leningrad – (formerly St. Petersburg) oldest manufacturing center in Russia developed by Peter the Great – Along the Volga River – dams & hydroelectricity – Used the Trans-Siberian railroad & rivers for transportation – Major resources/manufacturing: • Coal, timber, machinery, iron ore, and oil Former Soviet Union – Russia & Ukraine Machine building, optical products, medical equipment, shipbuilding, chemical production, food processing, textiles Fig. 11-7: Major manufacturing centers are clustered in European Russia and the Ukraine. Other centers were developed east of the Urals. Major Manufacturing Regions of Russia “Soviet Detroit” -Many resources throughout the vast expanse of land -Volga River provided an energy resource and transportation through canals Japan • • • • Very limited natural resources Imports raw materials to use in manufacturing 1/25 the size of the US Economic development started in the late 1800s • Established colonies, brought raw materials in • After WWII the US helped Japan recover Major Manufacturing Regions of East Asia -Japan imported raw materials from it’s colonial empire into Korea, Taiwan, and China -3 major belts in Japan? Kanto Plain (TokyoYokohama-Kawasaki) Kansai District (KobeKyoto-Osaka) Kitakyushu District Where are the Major Industrial Belts Today and Why? China • Major industrial growth occurred when communist planners took over in 1949 • Has many natural resources • Four Key Industrial Regions: – Northeast District – “Chinese Pittsburgh” – Northern Industrial – Shanghai & Chang – Guangdong Northeast District Shanghai & Chang Guangdong Why China? • HUGE labor force, low daily wages!! • Most companies send production portions of company to China instead of whole company because of this • Certain cities on the Pacific are SEZs (Special Economic Zones) or “open cities” to foreign investors. • Today China is moving manufacturing to the interior • Companies sending manufacturing work to China is called outsourcing or moved offshore Secondary Industrial Regions • 4 Asian Tigers- S. Korea, Taiwan, Hong King, Singapore – Called this b/c they are challenging Japan for dominance in Asia • S. E. Asia- Thailand, Malaysia, Indonesia, Vietnam • N. & S. America- Brazil, Mexico • S. Asia- India How does this change our world geographically?? • During last 30 years, industrialized countries have been going through what we call: – Deindustrialization- move industrial jobs to other regions with cheaper labor – Causes industrialized countries to switch to a Service Economy – US and UK are losing their industrial belts b/c of this shift What is a Service Economy and where are Services concentrated? •Origins of manufacturing boom • Sharp rise in oil prices in the 1970s caused increasing difficulty for core industrial regions to sustain competitive advantage. •Movement toward mechanization •Development of service & information industries Services in Broken into 3 Categories • Tertiary Industries – provides general services (car wash, landscaping) • Quaternary Industries – collection of information (insurance, finance, stocks) • Quinary Industries – scientific research, higher education, high level management Tertiary Industry • Decline of primary and secondary industries has ushered in an era referred to as the postindustrial phase – Part of the postindustrial phases includes: • Transportation, communication, and utility services • Highways, railroads, airlines, and pipelines • Telephones, radios, television, and the Internet • All facilitate the distribution of goods, services, and information • Every industrial district is served by well-developed transport systems Tertiary Industry: Netherlands Quaternary Industry • Includes those services mainly required by producers – Trade, wholesaling, retailing, and advertising – Banking, legal services, real estate transactions, and insurance – Consulting and information generation • Such activities represent one of the major growth sectors in postindustrial economies • Manufacturing is increasingly shunted to the peripheries Quaternary Industry: Hong Kong Quaternary Industry • If seen on a local scale information-generating industries seem to coalesce around major universities and research centers – Stanford and University of California at Berkeley helped make San Francisco Bay area a major center of such industry – Similar foci developed near Harvard and M.I.T. in New England – Triuniversity Raleigh-Durham-Chapel Hill “Research Triangle” of North Carolina Quinary Industry • One of the most rapidly expanding activities – Scientific research, higher education, high level management • With the approach of WWII, the quaternary sector began expanding rapidly • During the last three decades the quaternary and quinary sectors have experienced very rapid growth, giving greater meaning to the term postindustrial. How has Industry changed since the industrial revolution? • Ford and the assembly line: dominant mode of mass production during the twentieth century, production of consumer goods at a single site. 70 Fordist Fordist – dominant mode of mass production during the twentieth century, production of consumer goods at a single site. Post-Fordist Post-Fordist: Current mode of production • More flexible set of production practices • Goods are not mass produced. • Production is accelerated and dispersed by multinational companies that shift production, outsourcing it around the world. China, the birthplace of your Nike's and socks and underwear and …. Port of Hong Kong Significance of container shipping, break of bulk point/entrepot Time-Space Compression Through improvements in transportation and communications technologies, many places in the world are more connected than ever before. Time-Space Compression • Called Just-In-Time delivery or production – No more mass production of products – Ship goods when they are needed – Cuts down on warehouse storage, rent, & wasted parts – Just ship parts quickly when needed! Time-Space Compression • This created a Global Division of Labor – Ends high labor costs – Locate in several countries – Make more money for stocks • Research & development in core; manufacturing in periphery • Why? • Cheap Labor, Few Regulations, Tax Rates are Low Geography Dimensions of Economic Activity • Wealthier industrial regions were the most successful in establishing a postindustrial service economy. • Deindustrialization did little to change economic division between core & periphery. – Even in the manufacturing realm, mechanization & innovation production strategies allowed core industrial regions to retain their dominance. • Dominant manufacturing cores have experienced economic changes associated with economic shifts. • Trade itself is a tertiary economic activity • Patterns of trade vary by industry • Dominant flow is among & between core countries and newly industrializing countries. • Level of trade between peripheral countries is low. New Influences on the Geography of Manufacturing • Transportation on industrial location – Development of infrastructure: containers, refrigeration – Intermodal connections • Regional and global trade agreements – NAFTA, EU – WTO: ~150 countries, promotes free trade to eliminate quotas • Proximity to Energy sources in industrial location less important – Pipelines and tankers deliver fuel to far away places – 2.5 million miles of pipelines in NA Oil has brought wealth to countries outside the core: • Oil cartel formed OPEC (Organization of Petroleum Exporting Countries) • 80% of their money is tied to oil • Citizens are guaranteed: – – – – Housing Education Healthcare Pensions for retirement High-Technology Corridors • Found in wealthier core countries • By early 2000s, more than 60 countries had established such zones • Located near universities for educated work force Production of Televisions provides a good example of how changing multinational networks function • Three key elements in television production: – Research and design – Manufacturing components – Assembly • Production of televisions has shifted across the world over time. • Read page 378 & jot notes or illustrate how TV productions shows the global division of labor New Influences on Location 1. Service industries are not tied to raw materials & don’t need large amounts of energy 2. Market accessibility is more relevant Why Tertiary, Quaternary, & Quinary Industries Locate Where They Do: • Tertiary – transportation communication, locate where people are • Quaternary – banks (near businesses), credit card company (anywhere) b/c of communications • Quinary – government seats locate in capital cities, research near universities, corporate management in big cities Energy Importance in Industrial Location • Oil & gas replaced coal as the energy source • US consumption today (% of the world’s consumption: Oil – 27% Natural Gas – 37% • US reserves = 4% of world’s total • US & Europe are very dependent on foreign oil suppliers • Japan totally dependent Technopoles Several high-tech industries locate together • Drawbacks – Pollution (chemicals) – Required large amounts of water – Clear land to make room for their buildings – Silicon Valley - - - - - - - - >