ROI – $10.00 per bin location per year

DigitalBins.com is a new and powerful inventory management technology

Traditional dark, dumb bin locations make-way for DigitalBins computer addressable piece counting scales and brilliant multi-color LED clusters.

Scales are available in a variety of sizes from 2.5 inches wide to 4 feet wide.

Sensitivities range from .005 lbs. (1/4 washer) to 10,000 lbs.

The LED clusters contain six individually colored LEDs with special optical properties making them visible from far distances and at severe viewing angles.

The DigitalBins.com Inventory Management System (DBIMS) software uses scales and LEDs in concert to make every inventory management function faster, easier and more reliable.

DigitalBins is revolutionary. It is the only system on the market using scales and LEDs in concert to bring significant efficiencies to inventory management.

Techniques, methods and logic to orchestrate scales and LEDs were conceived at DigitalBins.

DigitalBins technology can be installed in a cabinet, in a drawer, on a rack, on wheels, in a locker or on existing shelving.

Features

Count 6,000 bin locations per minute

Perform a physical inventory every day

Identify and eliminate theft quickly

Detect and correct abuse of procedures quickly

Speed the auditing process

Brilliant LEDs communicate current inventory levels

Inventory visibility in the browser of any smart device

Instantly locate any SKU

Build kits

LEDs assist in locating parts, picking, receiving & kitting

Build-in RFID security monitor

Import and export data easily

Interface with any MRP system

Print barcoded labels

Email purchase orders automatically

Email replenishment reports automatically

Brilliant LEDs communicate messages at each bin

LEDs may be assigned by product class

Built-in WatchDog security system

Foreign Object Detection (FOD)

Anonymous picking & receiving

Picking & receiving using a picking ticket

Picking & receiving by Job

RFID secure and semi-secure shopping function

When the Inventory Monitor is processing, the top row of LEDs become Inventory Level LEDs where a yellow LED indicates the reorder level has been reached and a red LED means on-hand has fallen below minimum levels.

When the Inventory Monitor is processing, the bottom row of LEDs is reserved for user defined

LED messages. LED messages communicate information to the viewer about each bin.

For this user, the orange LED indicates a PO has been issued to our vendor, the white LED indicates that the vendor has shipped on our PO and the blue

LED indicates the vendor has not delivered within the contracted lead time.

The message LEDs can also be used to communicate that the bin contains expired goods , that the part is made of titanium , that a FOD ( foreign object ) has been detected, the bin contains hazardous goods , and so on.

With a few minutes of instruction, anyone can look at the 36 bins above and immediately know inventory levels and messages the LEDs are communicating.

The DigitalBins.com Inventory Management System software will make dumb bins come to life!

Who are potential DigitalBins customers?

Anyone who stores inventory by bin location.

MRO (Maintenance, Repair & Operations) is a multi-billion dollar segment. Many industries fit into this category including governments and the largest corporations in the world including Auto, Aviation, Rail, Bus, Delivery, Oil & Gas, etc.

VMI (Vendor Managed Inventory) has become very popular in the MRO space.

DigitalBins is a perfect fit for companies providing VMI services or for any MRO user.

Distributors and Manufacturers are by far the largest users of bins and bin locations. There are hundreds of thousands of distributors and manufacturers world-wide managing customer orders and or internal usage.

Most rely on MRP software provided by SCI, SAP, Epicore, Infor, QuickBooks, and others to manage inventory.

DigitalBins was designed to easily interface with any MRP system.

Medical Supplies Vitamins Baked Goods Cables Electrical Supplies Plumbing Supplies

ROI - Return on investment is a popular financial metric for evaluating the financial consequences of individual investments. A high ROI means that gains compare favorably to costs.

DigitalBins is a multi-function product. As with any multi-function product, ROI will differ based upon usage and circumstance, so, if you have a theft problem, your ROI on a multifunction product with a security system component will be more favorable then it will be for a user with no theft problem.

DigitalBins has many functions with more to come. Each is designed to increase efficiency and reliability and to enhance the user experience.

In following frames, we discuss ROI per DigitalBins function.

ROI - $22.10 per bin location per year

Lean Inventory

DigitalBins will allow you to maintain extremely lean levels of inventory by reducing to minutes the span in time from awareness of low inventory to replenishment action.

The system will email a requirement notice to internal buyer(s) or a purchase order to a vendor immediately upon a bin reaching its assigned minimum level. Copies may be emailed to five recipients.

For bins replenished by internal inventory, DigitalBins will email a replenishment report listing every SKU at or below the minimum level. The report includes an image of the SKU and a suggested replenishment quantity. The replenishment report is barcoded and can be used as a receiving document by the Advanced

Picking & Receiving functionality discussed earlier, making restocking easy and error free.

Est. Savings

Per Bin Per Year

5.00

15.00

2.00

22.10

• Leanest possible inventory levels allows you to decrease your investment in inventory

• Frees the purchasing agents to do other duties

• Insures manufacturing lines never stop due to empty bins

(frees cash @ 5% that is 50,000.00)

(15.00 To determine the need for a PO & enter it * 10,000 Pos = 150,000.00)

(100.00 per stoppage * 200 = 20,000.00

All calculations based on 10k bin locations, 1m Inventory valuation, 3 minutes to count each location, 10m in sales

ROI - $7.10 per bin location per year

Daily Physical Inventory – Machine to Machine (DigitalBins to WMS or MRP)

Everyone dislikes Physical Inventory! DigitalBins counts 100 bin locations per second, 10,000 in less than two minutes.

With this daily process in place, you will cycle count only bins where DigitalBins and your MRP system have differing counts. This eliminates physical inventory completely! It transforms the cycle counting into a purposeful reconciliation process.

Recognize theft quickly and correct procedural breaches like salesman taking samples without proper paperwork. Minimize balance sheet adjustments. Restore trust in the On-Hand quantity reported by your

MRP system.

Est. Savings

Per Bin Per Year

2.0% 2.00

1.5% 1.50

0.6% .60

2.0% 2.50

0.5% .50

7.10

• Eliminate or minimize theft, procedural breaches, etc. before they negatively impact the bottom-line and system integrity. (1m * 2% = 20,000.00 / 10,000 bins)

• Eliminate physical inventory completely, (3 minutes per bin * 10,000 bins / 60 = 500 man hrs. * 30.00 = 15,000.00)

•

Eliminate data entry of physical and cycle count tickets.

• Eliminate physical inventory shutdowns / business interruptions.

(10,000 locations / 120 hrs. * 50.00 = 6,00.00)

(5 days ; value = 20,000.00)

• Adjust book and actual inventory daily, for up-to-date financial statements and reliable inventory counts and valuation. (Value of timely information and accurate counts = 5,000.00)

All calculations based on 10k bin locations, 1m Inventory valuation, 3 minutes to count each location, 10m in sales

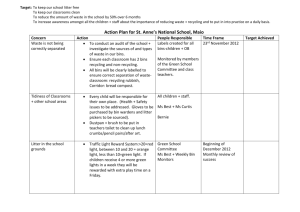

ROI – $10.00 per bin location per year

Part Locator

Enter an SKU number, scan the bar-code on the product, use the search-for feature or SKU image and the Part Locator will light a brilliant LED under the bin(s) containing that SKU.

The Part Locator will insure goods are received into the correct bin location. It will insure you've got the correct part to ship to a customer. It will help you find infrequently used inventory quickly.

Once you have selected a part, the Part Locator will allow you to go directly to the bin detail maintenance program where you may make changes, review purchasing or usage data, etc. You can view the detailed specifications of the part in image, .pdf or .doc format or follow a hyperlink to a web page.

Est. Savings

Per Bin Per Year

10.00

ROI – $10.00 per bin location per year

Part Locator

ROI - $15.00 per bin location per year

Advanced Picking & Receiving

Returns due to improper picking and receiving have a significant financial impact on the bottom line. One incorrectly received item will have a ripple effect throughout every department in the company. Incorrectly shipped goods require customer service time, re-order processing, re-picking, re-shipping, put-away of the returned item (hopefully in the correct bin), unrecoverable freight expenses, etc. The average return cost

150.00 no matter what the cost of the incorrectly shipped item is.

DigitalBins advanced picking and receiving functionality guides warehouse personnel to the correct bin using LEDs. It monitors and interacts with the operator during the transaction, verifies the accuracy of the pick or receiver by weight and informs the operator of a successful bin interaction using LEDs.

In today’s just-in-time environment, picking errors are the quickest way to lose a customer.

Est. Savings

Per Bin Per Year

10.00

5.00

15.00

• Picking and Receiving Errors

• The value of the loss of one customer

(1% sales)

(50,000.00)

All calculations based on 10k bin locations, 1m Inventory valuation, 3 minutes to count each location, 10m in sales

ROI - $30.00 per bin location per year

VMI Services

As you know, VMI providers charge for their services. When VMI services were compared to the old way of doing things, the extra costs could be justified. That was before DigitalBins. In fact, VMI providers are finding DigitalBins delivers ROI for them.

Why not take the time to compare the cost of your current VMI solution to an in-house DigitalBins

Inventory Management System.

DigitalBins will order parts automatically from your VMI provider or any supplier for substantially less per

SKU. Why continue to pay 1.20 for a .05 bolt. Why pay for unneeded services, technology fees, equipment rental fees, consignment fees, etc.

DigitalBins will allow you to control inventory in-house for substantially less.

Est. Savings

Per Bin Per Year

30.00

ROI – $25.00 per bin location per year

Kitting

The kitting process will make perfect kits every time.

The BOMs and RMs may be imported or DigitalBins will query your WMS/MRP DBMS. The kitting program will display the number of kits that may be built based on the RMs in each DigitalBin and the BOM detail.

The LED clusters display the quantity needed under each bin used in a BOM. The process guides the operator from RM to RM. One LED is turned off for each RM pulled. When the correct quantity is pulled, all

LEDs will flash and a barcoded RM label may be printed. When all RMs for the kit have been pulled, the computer will say “Kit Complete” and a barcoded BOM label may be printed.

This function may also be used as a pre-programmed process guide for mechanics, surgeons, etc.

Significant savings in time and accuracy will be realized.

Est. Savings

Per Bin Per Year

25.00

ROI – $25.00 per bin location per year

Kitting

ROI – $15.00 per bin location per year

RFID Crib Security System

This built-in security functionality will allow you to create a secure or semi-secure environment in any cabinet, crib or warehouse.

The process is started by an employee swiping an RFID card reader. DigitalBins will verify access. If a specific job and/or customer its to be charged, a job number and/or customer number may be entered.

Before the door is unlocked, DigitalBins will perform a speedy count, turn on the lights and then buzz to signal the door strike has been released. Once the door is closed, the RFID reader displays a red occupied

LED. The employee freely picks from or receives to any DigitalBin location. When the door is opened and closed, the lights are turned off, the RFID reader led will display a green LED, and DigitalBins will print a Bin

Ticket receipt of all activity.

This process eliminates theft and accurately assigns an employee, customer, job, etc. to every bin access.

Est. Savings

Per Bin Per Year

15.00

ROI – $15.00 per bin location per year

RFID Crib Security System

ROI – $10.00 per bin location per year

Bin Security - WatchDog

This built-in functionality will protect inventory after hours.

A scheduler kicks-off the WatchDog program. If any bin is touched while WatchDog is running, DigitalBins will time-stamp each bin access, blast the sound of a junk-yard-dog barking (or any .wav file) and send email or text messages to up-to five recipients per bin. Knowing the exact time will help if a video surveillance system is operational.

DigitalBins will generate a report of every part and quantity removed which will be helpful in filing a police report and insurance claim if any. This feature could save thousands in one incident.

In addition, this security feature will help to stop salesman from removing customer samples and put all staff on notice that the bins are watching!

Est. Savings

Per Bin Per Year

10.00

ROI – $20.00 per bin location per year

Cutting-edge technology, buzz and social benefits

DigitalBins makes every inventory management task simpler. LED lights assist with decision making and counting. They affirm for employees that their actions are in sync with the system or process. They make every job more enjoyable and stress-free.

DigitalBins can help to expand the diversity of employees. It will allow seniors, handicapped and non-

English speaking individuals who need to work, to be more productive. DigitalBins can help your company become more socially responsible!

Everyone feels better knowing they are a part of the future. Employees will immediately recognize the benefits and see DigitalBins as something new and very cool. Customers and vendors will wonder about the light show as they tour your facility. Your decision to invest in this new technology will create a positive buzz.

Est. Savings

Per Bin Per Year

20.00

ROI Per Function Per Bin Location Per Year

Est.

Lean Inventory $22.10

Daily Physical Inventory $7.10

Part Locator $10.00

Advanced Picking & Receiving $15.00

VMI Services (Vendor Managed Inventory) $30.00

Kitting $25.00

RFID Crib Security System $15.00

Bin Security – WatchDog $10.00

Cutting-Edge Technology, Buzz & Social Benefits $20.00

$154.20

Thank you for taking time today to learn more about DigitalBins.com.