PAS 99 presentation

advertisement

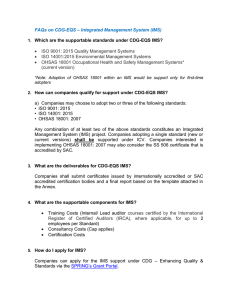

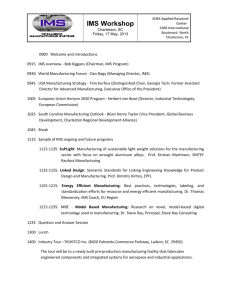

Integrated Management Framework Introduction What is PAS 99 Examples of Integrated Management Systems Auditing IMS Benefits & Barriers What the Certification Bodies don’t mention What is PAS 99 Specification issued by BSI ‘Recognised’ by Certification Bodies Framework by which you can manage all elements of your business ISO 9001 ISO 14001 OHSAS 18001 Sector Standards: ISO/TS 16949, ISO 13485 etc Specialist Standards: Organic Food, Fair Trade, Lexel, Sarbanes Oxley Principles of PAS 99 Based on ISO 14001 structure PDCA Cycle to support systematic management Risk Based Standard Helps is you really know your processes! Process identification with inputs & outputs are essential Structure of PAS 99 6 common requirements: Policy Planning Implementation & Operation Performance Assessment Improvement Management Review The Specification Practical Examples of Key Areas Risk Based Approach 4.3.1 Evaluation of Aspects & Impacts : evaluate the significant business issues & the associated risk Quality: Preventive Action? Automotive: FMEA Food: HACCP Medical Devices: Product Risk Assessment Environmental: Aspects & Impacts OH&S: Risk Assessment, HAZOP Corporate Governance: Corporate Risk Goal: Establish a common frame work to identify, evaluate and control business risks of any type. Legal & Other Requirements 4.3.2 Identification of legal & other requirements Environmental: licences, waste, water, WEE etc OH&S: HASAW, Manual Handling, PUWER, Consultation Human Resource: Working time directive, equality, disability etc Data Protection: Do you hold customer information? Products: CE Marking, design requirements Import/Export: Legal requirements, product specifics Software: Are you licensed correctly? Corporate Governance: New companies act & director liability Goal: Legal compliance (and keep the Managing Director out of court). Achieving Compliance Plan: •Identify requirements •Review arrangements •Identify gaps •Set objectives Do: •Implement & communicate •Set responsibilities •Write procedures •Establish controls •Training Act: •Corrective action •Preventive action •Management Review Check: •Monitor compliance •Audit & Inspection •Sample & measure •Report non conformities System Linkages Risk Assessment Legislation Business Controls Documenting Working Procedures 4.4.1 Operational Control - for example machine maintenance: OH&S: Wear your PPE, Use the permit to work, isolate the machine Product: Ensure machine is cleaned, set up for quality critical to quality parameters Environmental: Don’t throw the oil down the drain etc. Goal: One stop shop document for each process and task. Core Systems 4.4.3: Documentation requirements, 4.5.4: Handling non conformities, 4.6.2: Corrective & preventive action Control of documents & data Control of records Control of non conformities CAPA Goal: Common procedures for these systems and clear priority on CAPA for the business as a whole Management Responsibilities 4.2: Policy, 4.3.4: Objectives, 4.7 Management Review One policy Common (non conflicting) objectives One Management Review of the business Goal: Common vision, goals and priorities for the business as a whole IMS Audit 4.5.2: Internal Audit Saves time Must focus on processes (not system elements) Use auditors & specialists to achieve competency Carefully define the scope of the audit & criteria Goal: Common vision, goals and priorities for the business as a whole A Turtle Process Map With What? With Whom? Equipment Infrastructure Training Knowledge Skill Inputs What should we receive? Outputs What should we deliver? Process How Many? How? Performance Indicators Instructions Procedures Methods Some Barriers to Integration Perception: Can a good Environmental/Quality/H&S Manager cut it running an IMS? Fear: Is this a cleaver way to ‘right size’ the organisation? Too Hard: Sound fantastic Mike but… Lack of Control: Nice try Mike but I’ve just spent the last 5 years trying to get everyone to follow the Q/E/H&S procedures – we need to maintain the focus not dilute it! Implementing an IMS Write a policy for the IMS Define the system – write a well structured manual to act as your ‘instruction book’ Make sure you have well developed process understanding Install common system elements Benefits of an IMS Encourages risk management across the business Gives a competitive edge – more holistic approach to business management Stakeholder satisfaction – systemic approach to risk, governance across the business Common goals across the business You should not integrate to save a few £££ on Certifications costs! What the Certification Bodies didn’t tell you! Still need to be certified 3 times (i.e. ISO 9001, ISO 14001 & OHSAS 18001) Probably will not make any kind of cost saving Not all auditors are multi skilled (you may get 2-3 auditors) – Are all auditors competent to audit your business? So in conclusion PAS 99 – Simple framework to use Genuinely drives a risk based approach to management Simplifies systems Can lead to internal savings But… Translate your system Ensure common processes Ensure correct competencies are sustained