What is an Integrated Management System

advertisement

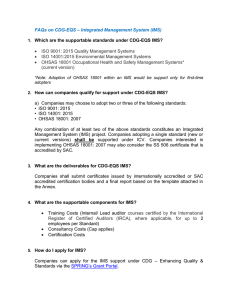

Presentation on Integrating Management Systems www.imsrisksolutions.co.uk What is an Integrated Management System ? Derived from ISO 14001 “the organizational structure, responsibilities, practices, processes and resources for developing, implementing, achieving, reviewing and maintaining the IMS Policy” Why Should There be an Integrated Management System? Need for a common system to ensure: • business focus • common purpose • simplicity of approach • no duplication of formal systems • minimal bureaucracy • less risk of conflict Benefits of this IMS Approach Provides a framework for a holistic management system that can embrace all the processes and elements that need to be controlled by the organization. What Areas Does an Organization Need to Manage? It depends on scope and nature of activities, complexity and size but typically: • product/service realization • customer satisfaction • supply chain • occupational health and safety • environmental management • security • people issues • finance Options Considered By ISO 1 2 3 4 Integration or Alignment CORE CORE CORE CORE E OH&S Q E OH&S Q Key Elements of ISO 9001:2000 ISO 9001:2000 Main Elements 4 Quality Management System 5 Management Responsibility 6 Resource Management 7 Product Realization 8 Measurement, Analysis and Improvement Quality Management Process Model Continual improvement of the quality management system Management responsibility Customer Customer Resource Management Requirements input Product realization Measurement, analysis and improvement Satisfaction output Product Process Approach • For an organization to function effectively it has to identify and manage numerous linked activities • An activity using resources, managed in order to enable transformation of inputs into outputs, can be considered as a process • Often the output from one process forms part of the input to another process Basic Process Model MANAGEMENT INPUT ACTIVITIES ENABLERS = CUSTOMER SATISFACTION OUTPUT Requirements of - ISO 14001 Figure 1 from ISO 14001 Continual Improvement Management Review Environmental Policy Planning Checking & Corrective Action Implementation & Operation Cradle to Grave EMISSIONS Extraction Transport Manufact. Delivery Use Service IMPACT & WASTE Mainten. Disposal IMS LA Issue 1. July 2001. Developed in association with MacGregor Associates Ltd. OHSAS 18001 is a specification This that is not a standard a “shall” document It is certifiable It is not accredited the major certification bodies have All adopted it and certification is going ahead world-wide. OHSAS 18001 Continual Improvement (Initial Status Review) Management Review Checking & Corrective Action OH&S Policy Planning Implementation & Operation Risk Assessment Definition of Hazard: A source or a situation with potential for harm in terms of human injury or illhealth, damage to property, damage to the environment, or a combination of these. Definition of Risk: The combination of the likelihood and consequences of a specified hazardous event occurring. Within IMS Hazard = Aspect Risk = Impact Definitions: ‘Hazard’ and ‘Risk’ - OHSAS 18001 Hazard - “A source or a situation with a potential for harm...” Risk - “The combination of the likelihood and consequence of a specified hazardous event” In an Ideal World Integrated Management Systems Standards would: • Be generically applicable world-wide • Use common terminology • Use the same definitions for similar terms • Use a common methodology - where this is possible • Have a common architecture • Allow a consistent auditing approach • Facilitate ease of use for those adopting them ISO Guide 72 Approach • Policy • Planning • Implementation and Operation • Performance Assessment • Improvement • Management Review Management Review Improvement Performance Assessment Policy Planning Implementation and Operation The Need for Integration Guidance • Reactive to pro-active management • Standards for OH&S, quality & environmental management - contrast, e.g., risk management, fire and security • Controversy • Organizations should in any event now be considering the development of an IMS The Case for an IMS • Cost-effective; facilitates decision-making • More rewarding careers • Objectives/processes of management systems very similar • Avoidance of duplication • Reduce chance of resolving one problem but creating another • Easier development of Standard Operating Procedures for OH&S and Environment Protection (EP) Policy Top management should ensure that the stated policy a) is appropriate to the organization b) includes a commitment to comply with all relevant requirements and continually to improve the effectiveness of the management system c) provides a framework for establishing and reviewing objectives d) is communicated, where appropriate, and is understood within the organization, and e) is reviewed for continuing suitability Planning • Identification of aspects and risks • Selection of significant aspects to be addressed • Objectives and targets • Identification of resources • Identification of organizational structures, roles, responsibilities and authorities • Planning of operational control • Contingency preparedness for foreseeable events Planning Key areas of planning that are distinct: 2.1 The organization should establish a process for identifying those aspects of its operation which need to be controlled and/or improved in order to satisfy the relevant interested party(ies). This includes research and design Where appropriate, legal requirements should be identified 2.2 The organization should establish a process for prioritising its aspects, so that those that would have a significant impact are readily identified for control measures where this is appropriate. 2.7 The organization should establish and maintain a process for identifying and responding to any potential emergency situation. The process should seek to prevent and mitigate the consequences of any occurrence. Implementation and Operation 3.1 Operation 3.2 Management of Human Resources 3.3 Management of other resources 3.4 Documentation and its control 3.5 Communication 3.6 Relationship with suppliers/contractors Key Issues for the IMS to be Effective • CONTROL - is there an adequate structure? • CO-OPERATION - are there adequate arrangements? • COMMUNICATIONS - are the arrangements effective? • COMPETENCE - are the systems and competencies available? HSE - 1995 Structure & Responsibilities Clear definition of responsibilities: include in job descriptions authority and resources arrangements: accountability reporting arrangements: clear and unambiguous where personal appraisal: include IMS performance Senior managers should demonstrate commitment by active involvement Management Review Improvement Performance Assessment Policy Planning Implementation and Operation Conclusion In considering a conclusion to the presentation it became apparent that a closing argument for integration isn’t needed. Integration clearly speaks for itself. To manage your organisational risks with a resilient management system you must integrate. The evidence from Corporate Europe today is Integration = Resilience www.imsrisksolutions.co.uk