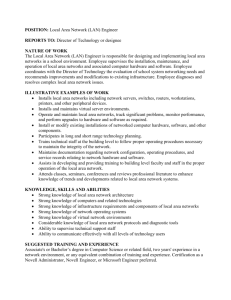

Engineered Leaf

advertisement

Central 2007 Central 2007 E A PALLAVI PHOR C OWNER TIM SCHROTENBOER WAFAA SABIL C JON JANSSON KEVIN CHIN Engineered Leaf E A C C AEC AEC Decision Matrix Green Funnel A Litrium Core Engineered Leaf A Strong Metaphor- Leaf Perimeter Zone Building Performance Central Organization Branched Organization E Standardized Structure E Creative Solution Engineering Complexity C Standardized Construction C Design Build Approach Contemporary Fabrication Key Features Within a tight footprint, the Engineered Leaf maximizes movement • Conceptualized Engineered Leaf and spaceas an through quality •a Eco-TARDIS Friendly & Sustainable Building experience. • Low Cost / Effective Construction • LEED Gold Certified • Value Engineered Project Location- UCLA, CA Access & Surroundings Site Context 192’-0” 230’-0” PARKING DECK SCIENCE BUILDING SOIL SITE 5 KSF Bearing Sandy Soil Seismic Zone 4 WATER DEPTH WIND 15 feet Mostly from West Climate Context PARKING DECK SCIENCE BUILDING TEMPERATURE 230’-0” 192’-0” SITE Winter max= 68F min 58F Summer max= 82F min 65F HUMIDITY Summer: morning 80%; afternoon 54% Winter: morning 65%; afternoon 50% PRECIPITATION Summer:1.75 inch, Winter:13.04 inch 1 Line Curve 2 Line +Curve Evolution of geometry 3 inspired by the growth of a leafENGINEERED LEAF Engineer Concept- Winter Quarter AEC 1. 2. Engineer Concept- Spring Quarter 3. Leaf engineered numerically to comply with nature’s Fibonacci series AEC NE Figurative Engineer Concept- Spring Quarter SW Topological Conceptual pine cone. AEC Exit Enter Engineer Site Layout AEC 24’-0” 24’-0” Storage/ Recycle M/E/P 24’-0” 24’-0” 24’-0” 24’-0” Comp. Room Restroom & Core Engineer Basement Level -10’-0” AEC 76’-0” 76’-0” Faculty Room Seminar Room Class Room Admin. Chair 38’-0” 38’-0” Restroom & Core Engineer First Floor Level 0’-0” AEC 76’-0” Student Offices 76’-0” Audi. Seminar Room Lab Class Room 38’-0” 38’-0” Engineer Second Floor Level 13’-0” Restroom & Core AEC Layout Auditorium Class Rooms Student Offices Rest Room Instructional Labs Class Rooms Engineer Architectural Evaluation AEC Egress Engineer Architectural Evaluation AEC 105’-0” 105’-0” PV Roof MEP Green Terrace Engineer Terrace Level 26’-0” Stairway AEC Engineer Elevations South Elevation North East West South AEC Engineer Elevations East Elevation N North Elevation E AEC Engineer Elevations South Elevation West Elevation AEC W S North Engineer 10’ 13’ 13’ Sections East West South AEC North Engineer 13’ 10’ 7’ Sections East West South AEC View from North View from North East Engineer Exterior Views AEC Engineer Exterior Views AEC View from South East Engineer Sun Path June 21 W Dec 21 E AEC Light & comfort Daylight in Classrooms, Faculty offices, Labs. Engineer Architectural Evaluation AEC Fenestration To avoid South & West Sun Engineer Architectural Evaluation AEC Predicted Life Cycle Cost Roof: PV Panel Roof Fenestration: Recycled crushed glass MEP Roof: Green Roof Cladding: Metal Composite Panels Engineer Architectural Evaluation AEC Gravity Loading - Slab/Self-Weight 70 psf - Partitions 20 psf - MEP 10 psf - Exterior Cladding 30 psf - Green Roof 25 psf - PV Panels 10 psf Engineer Dead Loads (UBC 1997 – L.A.) A EC Gravity Loading - Classrooms 40 psf - Offices 50 psf - Auditoriums / Corridors 100 psf - Access Floor Systems 100 psf - Light Storage 125 psf - Heavy Storage 250 psf Engineer Live Loads (UBC 1997 – L.A.) A EC Wind Loading Engineer Method 1 (UBC 1997) P = CeCqqsI Wind Speed = 70 mph qs = 12.6 psf Exposure B I = 1.0 (non-essential) Cq = 1.3 (in and outward) Height (ft) 0-15 20 30 Ce 0.62 0.67 0.76 A EC Earthquake Loading Engineer Site Context Seismic Zone 4 Santa Monica Fault Source Type B Distance = 2km NA = 1.3 NV = 1.6 A EC Earthquake Loading Engineer Seismic Zone 4 Soil Profile = SD 0.3 Importance = 1.0 R = 6.4 V 0.2 0.1 CA = 0.44NA 0 CV = 0.64NV 0 1 2 3 T (s) Base Shear Coefficient, V = 0.22W A EC Structural Plans 24’ 24’ “1st Building” Engineer Structural Grid 24’ 24’ 16’ Transition 18’ 16’ 24’ 16’ 12’ 12’ “2nd Building” 16’ 24’ 16’ 30’ 30’ 12’ 12’ 18’ A EC Structural Plans Engineer Basement Foundation Spread Footings Strip Footings 2’ Depth 4’ Width 24’ 24’ 24’ Walls 12” Thick Concrete A EC Structural Plans Engineer Ground Floor Columns W14x143 24’ Flooring 24’ Cast-in-place 24’ Concrete on Metal Deck Foundation Spread Footings A 30’ 12’ 12’ 18’ EC Structural Plans Engineer 2nd Floor Floor Framing Typical Beam: 24’ W18x71 Secondary Beam: 24’ W18x143 Tertiary Beam: 24’ W18x175 Flooring Sloped False Flooring A 30’ 12’ 12’ 18’ EC Structural Plans Engineer Terrace / Roof Lateral System Braces Around 24’ Perimeter HSS10x10x0.5 24’ Long Span 24’ King-Post Truss Arched Beams A 30’ 12’ 12’ 18’ EC 3D Structural Model Bracing for Segmented Building King-Post Lateral-Torsional Overview Truss Arches Buckling Engineer Long-Span Auditorium A EC 3D Structural Model Engineer Gravity Load Path A EC 3D Structural Model Additional Braces to Stiffen Connection Lateral FloorDiscontinuity Slab Acts Around as atDiaphragm Roof Perimeter Engineer Lateral Load Path A EC Structural Details Engineer Concrete Embed A Mentored by GPLA EC Structural Details Engineer Beam-Column (Web Connection) A Mentored by GPLA EC Structural Details Engineer Slab Edge A Mentored by GPLA EC Design Verification ETABS Building Model Engineer ETABS Analysis A EC Design Verification Girder Design: Moments – Gravity Loads Engineer ETABS Analysis A EC Design Verification Brace Design: Axial Loads – Gravity Loads Engineer ETABS Analysis A EC Design Verification Brace Design: Axial Loads – Earthquake Loads Engineer ETABS Analysis A EC Engineer Damage Mitigation Acceleration Content Damage A Prevention Measures EC ENVIRONMENTAL COST AND TIME SATISFY OWNER´S GOALS Engineer Construction Objectives • OCCUPANCY • LEED A E C Engineer Construction Site Plan A E C Soldier Piles & Wood Lagging Sheet Piles Pros Particularly effective adjacent to existing structures Cons Not appropriate Difficult in soils for sensitive soil prone to caving, and running sands condition and very Great advantage when there is a high ground water level dense soils Select Soil Nail Walls Typically used in dense to very dense granular soils Less cost effective in loose dense sands Engineer Shoring X A E C Engineer Cost Estimation A E C Engineer Cost Estimation A E C •Crane one: 90 days •Crane two: 50 days Engineer Crane Selection A E C Cost [$] 7 500 000 7 000 000 6 500 000 6 000 000 Bugdet Winter Estimate Spring Estimate Engineer Cost Evolution A E C CONSTRUCTION STARTS SUPERSTRUCTURE DONE INNER WALLS DONE COMPUTER ROOM DONE CONSTRUCTION FINISHED Sept 21 Dec 31 Mar 04 Apr 15 Jul 15 Engineer General Time Schedule A E C Engineer Structure Time Schedule A E C • • • • • • • • Roof – 30 days Painting – 30 days False floor – 30 days Auditorium – 40 days Inner walls – 45 days Installations – 60 days Outer walls + facade – 75 days Additional installations – 40 days Engineer Construction Times A E C MEP Engineer Under floor air distribution system Separate system for bathrooms Regular system in basement SUPPLY RETURN A E C Plenum Raised Floor Room Cavity MEP integrated building structure. Engineer MEP A E C Energy Usage: 10 kWh / SF,yr DC Rating: 61 kW Total Energy Cost: 29 000 $ / yr Energy Value: 11 000 $ / yr Calculated Energy Cost CA: 12 cent / kWh Pay Back Time - 10 years Regular PV-panels 20 16 20 19 20 22 20 25 20 28 20 31 600000 500000 400000 300000 200000 100000 0 http://rredc.nrel.gov/solar/codes_algs/PVWATTS/version1/US/code/pvwattsv1.cgi Engineer PV-Panels A E C Building Envelope During Construction • Accessible Green Roof • Eco- Friendly Materials • NE Side Lighting • Lean Construction • PV Panels Inside Building Site • Under Floor Air Distribution System • Permeable Pavement • Earthquake Damage Prevention • Water Harvesting • Wastewater Treatment System • Bike Racks Engineer Sustainability • Sustainable Elevator • Recycle Center A E C Engineer LEED A E C CO2 Reduce CO2 Embedded In Construction • Steel Structure • Eco- Friendly Materials • Material Reusage Reduce CO2 During Lifecycle • PV-Panels •Interior Flexibility Reduce Transportation • Local Suppliers, Materials & Contractors • Close To Public Transportation • Accessible Green Roof • Fast / Effective Construction Erection • Under Floor Air Distribution System • Lean Construction Engineered Leaf will contribute to a new era of environmental buildings. Team Interaction GOAL A E C C Team Interaction 1st ATTEMPT A E C C (January – February) Team Interaction GOAL A E C C Team Interaction 2nd ATTEMPT A E C C (February - March) Team Interaction AT LAST ! A E C C (March - April) Spring Improvements Winter Presentation Screenshot Additional Weekly Meeting – Owner Involved Once a Week At Least 2 Mentor Meetings per Team Member Increased Use of ThinkTank Design Evolution Hmm… They did OK.teach Let’sthis do it. not in class. Curves!! Don’t you love it? NO! is Yeah.Straight We can cheaper and make it happen!! faster!$! This class isn’t meant to be easy! We can do it! Design Evolution E C Architectural Massing Concept E C A Final Solution A Refined Architectural Concept A C E Integrated Structural/CM Solution Lessons Learned ”Final iteration = Work in progress.” – Pallavi ”Be positive. Be patient. Be pliable.” – Tim ”Language barriers are often higher than Mount Everest.” – Jon ”Transparency between each discipline is crucial.” – Kevin Special Thanks Paola Sanguinetti, Georgia Tech Greg Luth, GPLA David Bendet, HOK Helmut Krawinkler, Stanford Adhamina Rodriguez, Swinerton Eric Elsesser, Forell Elsesser John Nelson, UWMadison Imagine Lab, Georgia Tech Our Classmates Wafaa C E Sabil A RENATE! Patrik Lindstrom, PEAB Sweden Mats Bjale, PEAB Sweden Weine Hagg, PEAB Sweden Johan Bjornstrom, Chalmers Hans Bjornsson, Chalmers Per-Erik Josephson, Chalmers Thank you!