Industrial Automation

advertisement

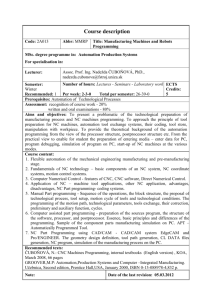

Industrial Automation Automation Industrielle Industrielle Automation 1.5 Control System Architecture Arquitectura de control Architecture de Contrôle - Commande Leittechnik-Architektur 1.5 Control System Architecture 1 Introduction 1.1 Automation and its importance 1.2 Applications of automation 1.3 Plants and controls 1.3.1 Open loop and closed loop control 1.3.2 Continuous process 1.3.3 Discrete process 1.3.3 Dual plants 1.4 Automation hierarchy 1.5 Control System Architecture Industrial Automation Control system hierarchy 1.5 - 2 Principle The control system is a communication system consisting of controllers and links. The structure of the control system should reflect the structure of the plant Ideally, each unit of the plant should have its own controller, interacting with the controllers of the other, related units, mirroring their physical interaction. Example: Airbus: a wing is delivered with its own computers. Industrial Automation Control system hierarchy 1.5 - 3 System Architecture Conceptual model presenting • Structure • Relationships • Behavior Including • Description of most important elements of system • Mapping of functionality onto hardware and software components • Description of top-level human interaction with components Goal: • support reasoning about elements, structure and behavior • guide for implementation Industrial Automation Control system hierarchy 1.5 - 4 Example: Power plant control - 1980 (!) Control systems still look similar Industrial Automation Control system hierarchy 1.5 - 5 Buses and processors in industrial plants instrument bus (mimic board) disk Process pictures open network, WAN Operator panel Mimic board Process Data Base workstation bus station station Logging plant network (500m .. 3 km) – includes control network processor pool P P P C P PLC nodes (multi-processors) P C P node bus I/O MEM I/O MEM BC directly coupled input/ output fieldbus (30m..2 km) control stations backplane bus sensor bus sensor bus (0,5.. 30 m) transducers plant (Werk, usine) M valve thermo-couple Industrial Automation position motor Control system hierarchy 1.5 - 6 Example: Production management system production planning enterprise network scheduling maintenance quality control plant network transportation cell control cell manufacturing cell control floor network robot controller milling machine rail-guided vehicle Industrial Automation Control system hierarchy 1.5 - 7 Plant with process (e.g. chemical) and electrical (substation) parts Engineering Workplaces plant network vertical communication IEC 61850 connectivity server CN Connectivity Server (and router) Aspect Servers process network substation network horizontal communication interface controller CI871 PB PI PN PI PB PI PN PI PB PI Engineering PN PI PB PI PN PI PB PI PN PI Profibus horizontal communication Profinet RSTP Industrial Automation Engineering LANs are separate: there is no IP routing between them SAN IEDs PI PI PI PI = Process Interface MU = Merging Unit MU PI MU PI bay bus Control system hierarchy 1.5 - 8 Example: Newspaper Printing Architecture MPS = Managed Print Services Each level has its own bus ! Industrial Automation Control system hierarchy 1.5 - 9 Example: ABB Industrial IT (redundant system) Workplaces (clients) Plant Network / Intranet Enterprise Optimization (clients) 3rd party application server Firewall Mobile Operator Plant Network (Ethernet) connectivity server aspect server application server engineering workplace Control Network (Ethernet) Serial or fieldbus Field Bus Programmable Logic Controller AC 800C Redundant AC 800M 3rd party controllers, servers etc touch-screen Field Bus sensor network Industrial Automation Control system hierarchy 1.5 - 10 Centralized (Hierarchical) Control Architecture Central Computer (Mainframe) Group Group Group Control Control Control Sensors, Actors PLCs plant Classical, hierarchical, centralized architecture. The central computer only monitors and forwards commands to the PLCs Industrial Automation Control system hierarchy 1.5 - 14 Decentralized Control System (DCS) hierarchical (vertical communication) engineering workstation operator workstation data logger peer-to-peer (horizontal communication) plant bus controller controller controller controller field bus plant all controllers can communicate as peers (without going through a central master), restricted only by throughput and modularity considerations. Industrial Automation Control system hierarchy 1.5 - 15 Hierarchies are simple and traditional Industrial Automation Control system hierarchy 1.5 - 16 but Distributed Control Systems reflect a more complex world.... Industrial Automation Control system hierarchy 1.5 - 17 Assessment 1. What is a bus and why do we have more than one kind of them in a plant? 2. Name the parts of a typical hierarchical control system its busses and controllers 3. How does the network hierarchy relate to the plant control hierarchy? 4. What is the difference between a centralized and a decentralized control system ? What are the (dis)advantages of the two approaches? Industrial Automation Control system hierarchy 1.5 - 18