Networks, Signals, & I/O

by

Ed Red

Area

Controller

Factory

Level

MMS, TCP/IP Backbone

Bus Cycle

Time

< 1000 ms

Cell

Level

Profibus-FMS

Bus Cycle

Time

< 100 ms

Field

Level

Bus Cycle

Time

< 10 ms

Profibus-DP

Drive

ME 486 - Automation

I/O

Profibus-PA

Valves

Field

Device

Transmitter

Field

Device

Networks

Computers in a factory use

Local Area Networks (LAN's),

ranging from feet to miles, to

communicate with each other.

Devices like PLC's, CNC machines, robots, data collection devices, vision

systems, etc., communicate maintenance and monitoring data, schedules,

process programs, and I/O.

Reference site:

http://www.wmpenn.edu/PennWeb/Academic/ArtsTech/CompSci/Networks/LAN-Overview/Lanover.html

ME 486 - Automation

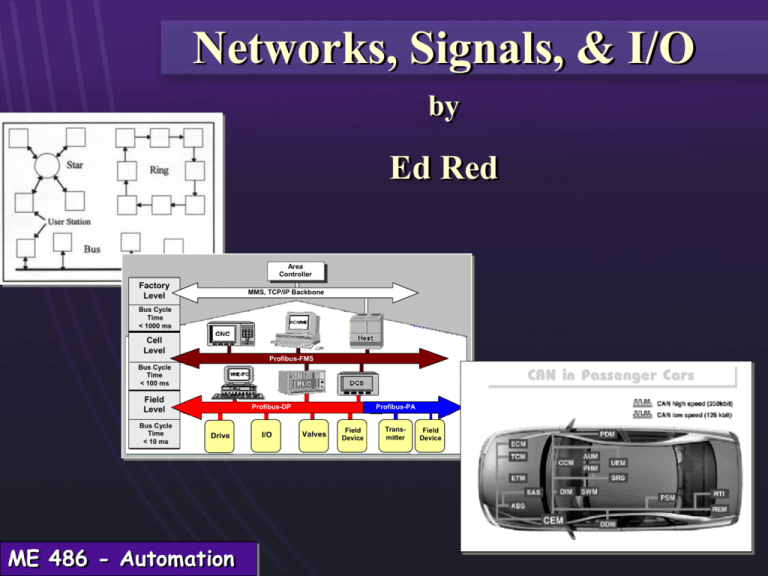

Network topologies

Star network - Central station handles

all communications between computer

stations.

Ring network - Stations are connected

in continuous ring, requiring that

messages be relayed between stations

until the message gets to the right station. Messages must carry a station

address.

Bus network - Consists of a single transmission line to which stations

attached. This type is used in Ethernets, and most commonly used in

factories today.

ME 486 - Automation

Network access

Star network access - central station coordinates communication

Ring and bus access - two access methods:

1) token passing

2) carrier-sensed multiple access with collision detection (CSMA/CD).

In the token method a token (code) is passed from station to station, with only those

stations knowing the code having the right to access the message. In the CSMA/CD

method each station waits until the network is clear until it sends a message. Any

failure (such as collisions with other message packets) will result in a retry.

ME 486 - Automation

Network communications

Twisted pair - Two or more copper wires twisted along length of line. Noise

susceptibility, and low bandwidth, but inexpensive. Used in phone lines,

but not usually in factory floor networks.

Coaxial Cable - One or more strands of wire shielded by outer metal shield,

then covered with insulation - high bandwidth, noise resistant, and

typically used in factory networks.

Fiber Optics - Continuous optical fibers of glass or other material which

can transmit light - high bandwidth, impervious to noise, but expensive.

Requires mode conversion between electrical mode to light mode.

Wireless – Wireless high frequency transmission of data.

ME 486 - Automation

OSI network protocol spec

1. Physical layer. This layer is concerned with the transmission of raw bits

across the network lines. It defines the data transmission rate and the

type of transmission medium.

2. Data link layer. This layer is concerned with the transfer of units of data

across the local area network. It deals with the resolution of contentions

when two devices are attempting to transmit at the same time, the size

of the units of data, detection and correction of errors in data

transmission, etc.

3. Network layer. The network layer is concerned with the routing of

packets of data from source nodes to receiving nodes throughout the

network It stores and relays data traveling between the nodes in the

network as part of this function.

ME 486 - Automation

OSI network protocol spec

4. Transport layer. This layer is responsible for the reliable delivery of data

from originating device to destination device in the network. It works

with layer 3 in order to accomplish this function.

5. Session layer. The function of the session layer is to support an orderly

dialogue between devices using the network. It deals with network

security issues, re-synchronizing the data in the event of a transmission

failure. and similar problems.

6. Presentation layer. This layer is concerned with negotiating syntax and

format for the data exchange between the sending and receiving devices.

One way of accomplishing this is to require all devices to encode data in

a common format.

ME 486 - Automation

OSI network protocol spec

7. Application layer. This layer provides the interface with the user for

specific applications. These applications deal with problems such as

transfer of files between devices, remote job entry, message handling,

access of files located at one device from another device. etc.

ME 486 - Automation

OSI network protocol spec

7. Application layer. This layer provides the interface with the user for

specific applications. These applications deal with problems such as

transfer of files between devices, remote job entry, message handling,

access of files located at one device from another device. etc.

ME 486 - Automation

Serial communications

1 The UART: What it is and how it works

The Universal Asynchronous Receiver/Transmitter (UART) controller is the key component

of the serial communications subsystem of a computer. The UART takes bytes of data and

transmits the individual bits in a sequential fashion. At the destination, a second UART reassembles the bits into complete bytes.

Serial transmission is commonly used with modems and for non-networked communication

between computers, terminals and other devices.

Copyright © 1996 Frank Durda IV <uhclem@FreeBSD.org>, All Rights Reserved. 13 January 1996.

UART

ME 486 - Automation

UART

OSI network protocol spec

1.2 Asynchronous Serial Transmission

Asynchronous transmission allows data to be transmitted without the sender having to

send a clock signal to the receiver. Instead, the sender and receiver must agree on timing

parameters in advance and special bits are added to each word which are used to

synchronize the sending and receiving units.

When a word is given to the UART for Asynchronous transmissions, a bit called the "Start

Bit" is added to the beginning of each word that is to be transmitted. The Start Bit is used

to alert the receiver that a word of data is about to be sent, and to force the clock in the

receiver into synchronization with the clock in the transmitter. These two clocks must be

accurate enough to not have the frequency drift by more than 10% during the transmission

of the remaining bits in the word.

After the Start Bit, the individual bits of the word of data are sent, with the Least

Significant Bit (LSB) being sent first. Each bit in the transmission is transmitted for exactly

the same amount of time as all of the other bits, and the receiver “looks” at the wire at

approximately halfway through the period assigned to each bit to determine if the bit is a 1

or a 0. For example, if it takes two seconds to send each bit, the receiver will examine the

signal to determine if it is a 1 or a 0 after one second has passed, then it will wait two

seconds and then examine the value of the next bit, and so on.

ME 486 - Automation

OSI network protocol spec

1.2 Asynchronous Serial Transmission (cont)

The sender does not know when the receiver has “looked” at the value of the bit. The

sender only knows when the clock says to begin transmitting the next bit of the word.

When the entire data word has been sent, the transmitter may add a Parity Bit that the

transmitter generates. The Parity Bit may be used by the receiver to perform simple error

checking. Then at least one Stop Bit is sent by the transmitter.

When the receiver has received all of the bits in the data word, it may check for the Parity

Bits (both sender and receiver must agree on whether a Parity Bit is to be used), and then

the receiver looks for a Stop Bit. If the Stop Bit does not appear when it is supposed to, the

UART considers the entire word to be garbled and will report a Framing Error to the host

processor when the data word is read. The usual cause of a Framing Error is that the

sender and receiver clocks were not running at the same speed, or that the signal was

interrupted.

Regardless of whether the data was received correctly or not, the UART automatically

discards the Start, Parity and Stop bits. If the sender and receiver are configured

identically, these bits are not passed to the host.

If another word is ready for transmission, the Start Bit for the new word can be sent as

soon as the Stop Bit for the previous word has been sent.

Because asynchronous data is “self synchronizing”, if there is no data to transmit, the

transmission line can be idle.

ME 486 - Automation

Factory floor communication standards

MAP (Manufacturing Automation Protocol) – not used much today

GEM (Generic Equipment Model) - generalized model that describes a

recommended implementation of the SEMI Equipment Communications

Standard II [SEMATECH]. It is used in communications and control of

semiconductor manufacturing equipment, and provides a reference model

for any type of equipment. It contains functionality that can apply to most

equipment, but does not address unique requirements of specific

equipment. [SEMI E30-94]

ME 486 - Automation

Network Assessment

1.

Explain the GEM protocol.

2.

Who are some GEM vendors (Cimetrix is one) and who are some GEM users

(Motorola is one)?

3.

Who is Sematech (developed GEM spec)?

4.

Explain the Serial (RS 232, 485, etc.) protocol?

5.

What is difference between RS 232, RS 422, RS 485, etc.?

6.

Show some examples of message/packet formats using ASCII. What does ASCII

stand for?

7.

What are typical network communications limitations? What is IEEE 1394?

What is Ethernet? Can Ethernet be used as a real-time network?

8.

What are possible communication speeds in the different modes/protocols?

9.

What type of communications networks do modern machine tools and robots

use?

10. What do modern factory networks look like?

ME 486 - Automation

Programmable Logic Control (PLC)

Definition - dedicated computer for rapid processing

of simple logic instructions in a defined time.

Purpose - send and read signals that can be used to

control and monitor devices.

Process - one of scanning all the devices (sensors,

timers, etc.) in a cyclical time period.

ME 486 - Automation

PLC Control Approaches

Logic control method - This closed-loop method uses conditions

and events to signal completion of a given step, and then

triggers the execution of some other event. This is an

asynchronous method of process control, because it does not

always proceed in a constant time period.

Sequencing method - This open-loop method uses timers to

trigger the completion of one step and the beginning of the next.

This is a synchronous control method.

ME 486 - Automation

Logic Control Elements

PLC's are typically

programmed using

Boolean logic, shown

figuratively by logical

AND, OR, and NOT

gates.

ME 486 - Automation

Logic Control Elements

AND, OR, and NOT

gates are then used to

define two more logical

elements - the NAND

and NOR gates - also

shown with their truth

tables.

ME 486 - Automation

Boolean algebra

+ = “or”

ME 486 - Automation

= “and”

Ladder logic diagrams

Ladder logic diagrams display the various logic

elements (shown above) along horizontal lines

connected to two vertical ladders.

ME 486 - Automation

Ladder logic example

Suppose we want to use a programmable logic controller to handle the

control circuitry to require an assembly line to be started in low speed

If low speed

button pushed

and in high speed. The following inputs and outputs

before

permitting

operation

button

to stop line not pushed and

are

defined:

it is not running in high speed,

then start in low speed.

11 = momentary spring push button to signal to start

the line in low speed

00 = momentary spring push button to signal to switch

the line to high speed

01 = momentary spring push button to stop the line

20 = low speed load

21 = high speed load

ME 486 - Automation

Solution:

Ladder logic example

Process will mix ingredients,

first adding ingredient A until

level reaches sensor 2, then

adding ingredient B until

level reaches sensor 1. The

mix is then stirred for a

period of time, and tank is

emptied. Investigate the

control logic required.

ME 486 - Automation

Ladder logic example

How would you

write the ladder

logic for this

problem?

ME 486 - Automation

Ladder logic example

X1, X2 = sensors

S1, S2, S3 = solenoids (relays)

M = motor (relay)

T1 = tank stir period

T2 = drain period

X2

S3

S1

X1

X2

S2

X1

M

M

TMR

T1

T1

S3

S3

TMR

T2

ME 486 - Automation

Ladder logic example

Address

Low =

0000

High =

0001

Motor =

0500

Relay =

1000

ME 486 - Automation

Fieldbus I/O

Fieldbus is a generic term that describes a new digital communications

network that is being used in industry to replace the existing 4-20 mA analog

signal standard.

The network is a digital, bi-directional, multi-drop, serial-bus communication

network used to link isolated field devices, such as controllers, transducers,

actuators and sensors.

Bi-directional means it is a duplex port; the data can be transmitted in two

directions at the same time.

Multi-drop is also referred to as multi-access and it can be interpreted as a

single bus with many nodes connected to it.

Serial-bus means the data is transmitted serially according to RS232 or

RS485 protocol. Profibus uses RS485 protocol.

ME 486 - Automation

Fieldbus I/O

Most fieldbus technologies are based on the Controller Area Network (CAN) protocol

developed in the late 1980's for serial communications between automobile modules

with high resistance to noise and an ability to detect errors.

ME 486 - Automation

CAN - Controller Area Network

ISO 11898 standard

• Uses OSI two lowest layers - data link and physical layers.

• Chips embedded in the physical modules/devices, and interfaced

to physical network.

• Transmission rate can vary from 250 KB up to 1 MB (per second

understood).

• Physical layer uses differential transmission on a twisted pair

wire.

• Non-destructive bit-wise arbitration controls access to the bus.

ME 486 - Automation

CAN - Controller Area Network

ISO 11898 standard

• Messages small (at most eight data bytes) and protected by

checksum.

• No explicit address in the messages, instead, each message carries

a numeric value which controls its priority on the bus, and may

also serve as an identification of the contents of the message.

• Elaborate error handling scheme results in retransmitted messages

when they are not properly received.

• Means for isolating faults and removing faulty nodes from bus.

ME 486 - Automation

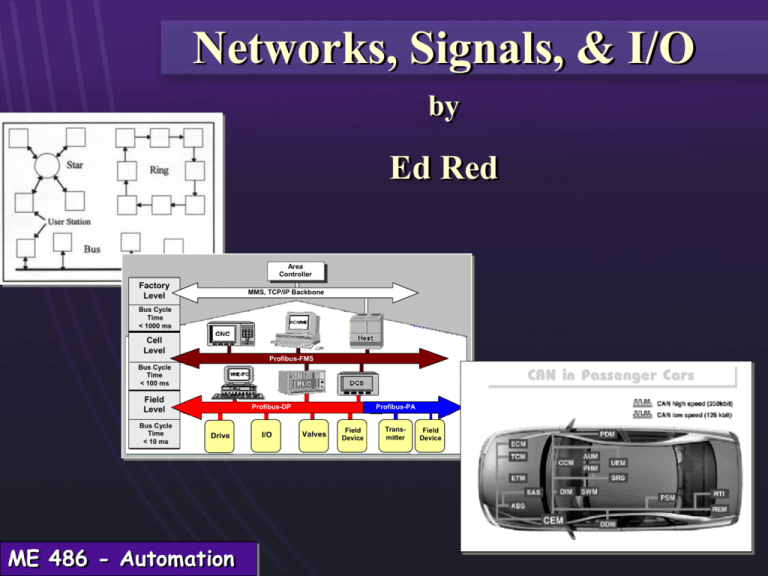

Profibus Fieldbus

Profibus is a vendor-independent, open fieldbus standard for a

wide range of applications in manufacturing, and process

automation. Devices configured by different manufacturers can

communicate without special interface adjustments. Profibus

can be used for both high-speed, time-critical data transmission

and extensive complex communication tasks.

Profibus family consists of three compatible versions:

Profibus-DP

Profibus-PA

Profibus-FMS

ME 486 - Automation

Profibus Fieldbus

Profibus-DP:

Designed for communication between automation control systems and distributed

I/O at the device level (only card used in EAAL).

Profibus-PA:

Designed for process automation….permits sensors and actuators to be connected

on one common bus.

Area

Controller

Profibus-FMS:

For communication tasks at

the cell level and can be used

for FMS services.

Factory

Level

MMS, TCP/IP Backbone

Bus Cycle

Time

< 1000 ms

Cell

Level

Profibus-FMS

Bus Cycle

Time

< 100 ms

Field

Level

ME 486 - Automation

Bus Cycle

Time

< 10 ms

Profibus-DP

Drive

I/O

Profibus-PA

Valves

Field

Device

Transmitter

Field

Device

Profibus fieldbus in EAAL

The Profibus API set is a set of C/C++ functions provided with the Synergetic

DP card software that can be embedded into a user-customizable software

interface provided with CIMServer. Once compiled and linked to make a

customized CIMServer version, CODE client processes can directly

communicate with the

CODE (Cimetrix Open Development Environment)

Profibus-DP I/O

CxGetSignal()

Profibus-DP card for I/O

Client

CxSetSignal()

Process1

…

data exchange. .

Client

Profibus-DP Card

DPM

Process2

Data Exchange

CIMServer

CIMTools

RS485

Signal

Table

I/O Modules

ME 486 - Automation

Signal File

Device Driver Interface

(read upon CIMServer startup)

User Defined Functions

Profibus API Set

CODE Functions

Configuration Blocks

Initialization Blocks

Wago I/O modules

The digital input module receives

signals from digital field devices

(sensors, etc). The physical

connection of the WAGO module is

shown. The middle two wires are for

the sensor power supply. The other

two wires are signal input/output

and signal ground.

ME 486 - Automation

I/O Assessment

1.

Who are the primary PLC vendors?

2.

What are typical costs per I/O?

3.

How fast can I/O be processed (in milli-seconds)?

4.

What are some of the newer programming interfaces?

5.

How are PLC's integrated into the control of a mechanism such as a machine

tool?

6.

How is analog I/O handled?

7.

How does the fieldbus I/O technologies compare to the conventional PLC

technologies? In costs, differences, protocol, etc.

8.

Who are primary vendors of fieldbus technologies?

ME 486 - Automation