APICS CPIM Courseware Update

Date: November 18, 2009

CPIM Courseware Update

Jerry Kilty, CFPIM, CIRM, CSCP

Quality Management Solutions, Inc.

CPIM Courseware Update Plan

• Three-year plan

– 2008: Rewrite BSCM

– 2009: Rewrite DSP and SMR

– 2010: Rewrite MPR and ECO

– 2008, 2009, and 2010: Update all courseware to be

consistent with the latest exam content manual (ECM)

Today’s Agenda

•

•

•

•

•

•

Instructional design changes

Content changes in the new DSP

Content changes in the new SMR

Updates to MPR, ECO and BSCM

Preparing to teach

Summary

Instructional Design of New DSP

and SMR Courses

Learning Objectives

From:

Objectives of Session 5

Understand global sourcing and distribution

and other international issues of managing

the supply chain

Explain the strategic relationship among

alliance members of the supply chain

Recognize how the choices and

development of information technology

affect the supply chain

Specific, measurable

objectives to guide

instructor and students

5-3

Strategic Management of Resources, Version 1.4 – January 2009

© 2009 APICS CONFIDENTIAL AND PROPRIETARY

To:

Learning Objectives

Supply Chain Management

Learning Objectives (cont.)

– Describe the relationship between the supply network and an

organization’s supply chain.

Managing Supply Chain Relationships

– Explain that supply networks consist of the flow of quality, speed,

– Differentiate between arm’s-length and long-term partnerships.

dependability, flexibility, and cost among operations.

– Explain the objective of disintermediation.

– Explain the role of supply chain management in managing flows

– Describe the advantages of outsourcing.

among operations owned by different organizations.

– Describe the advantages of vertical integration.

Capacity Planning

– Explain the benefits of supplier reduction.

– Explain the advantages and disadvantages of large- and small– Explain the improvements companies can make to reduce the

scale facilities.

bullwhip effect.

– Describe the impact of scale of operations on capacity planning.

– Differentiate between lead and lag capacity strategies.

53

© 2010 APICS CONFIDENTIAL AND PROPRIETARY

54

© 2010 APICS CONFIDENTIAL AND PROPRIETARY

Example IG Page and

Transition Slide

• Transition slide header in IG

corresponds to new transition slides

• Smaller slide graphics

• More instructor guidance

• References given

• One-column format

• New icons

Example PW Pages

Updated and improved content

Problems and Solutions

Problem Icon

Solution Icon

Build Slide Icon

Problem 1.2 Solution

Date

Quantity

Received

Unit

Cost

($)

March

─

10

0

─

14

0

April

100

10

1,000

70

14

980

May

100

12

1,200

30

14

420

40

12

480

60

12

720

10

10

100

June

July

100

─

14

16

Inventory Usage Issue Unit Issue Value

Value ($) Quantity Cost ($)

($)

1,400

─

─

Cost of goods sold = $2,700

July starting inventory of 90 at $10

$900

Vocabulary Check

• ECM Key terminology

• Reinforces dictionary definitions

• Matching or crossword

Performance Check Answers

“Wiki” Activity

• Second half of last session

• Students work collaboratively to build a knowledge base

on several topics (similar to “Wikipedia” approach)

• Students then write mock exam questions

• Students take the mock exam

• Added as appendix to MPR, ECO, DSP, and SMR

Content Changes To DSP

And SMR

New DSP and SMR Courses

• Why the Change?

– Update content to meet new 2010 ECM

requirements

– Improve the narrative

– Improve participant content and instructor guidance

– Include more interactions and activities

– Reinforce key terminology

– Make a visual impact

– Improve the experience for the instructor and

students

DSP Course Roadmap

Session:

1. Inventory policies

2. Inventory planning

3. Information used in the

material planning process

4. MRP mechanics: the

basics

5. Using MRP outputs and

managing projects

6. Detailed capacity planning

7. Detailed capacity

management

8. Establishing supplier

relationships

9. Supplier partnerships and

review activity

Key Content Changes - DSP

• New and improved performance check questions

• Changed the MRP Mechanics section to be more

interactive

• Expanded material planning content in project, flow

and lean environments

• Updated the procurement section to support suppliercustomer collaboration and logistics approaches to

accelerating the supply chain

Key Content Changes - DSP (cont.)

• Added ECM emphasis on:

– Service industry content

– Project management

– Role of lean/JIT

• in resolving sales and operations planning

conflicts

• on improving throughput and reducing inventory,

and the financial implications thereof

• Improved the process flow scheduling and line

balancing content

Reference Changes—DSP

APICS CPIM DSP reprints were updated from

2001 to 2010

SMR Course Roadmap

Strategic Management of Resources

1.

3.

4.

Developing the

Business

Strategy

The Global

Environment

and

Sustainability

Operations

Strategy

Operations

Strategy Choices

and Financial

Measurement

Aligning

Operations with

Supply Chain

Partners

Infrastructure

Systems

Change

Management

Case Studies

and Review

Activity

5.

13

2.

6.

7.

© 2010 APICS CONFIDENTIAL AND PROPRIETARY

8.

Session:

1. Developing the Business

Strategy

2. The Global Environment

and Sustainability

3. Operations Strategy

4. Operations Strategy

Choices and Financial

Measures

5. Aligning Operations with

Supply Chain Partners

6. Infrastructure Systems

7. Change Management

8. Case Studies and Review

Activity

Key Content Changes - SMR

• Increased emphasis or expanded coverage of

– Business strategy development (competitive forces,

SWOT analysis)

– Role of operations strategy and performance

objectives in supporting the business strategy

– Supply chain management strategies

– Financial analysis/measurement of operations

Key Content Changes - SMR

• New content in the following areas:

– Supply network design and ownership issues

– Expansion into foreign markets and globalization

– Sustainability and corporate social responsibility

– Risk assessment and mitigation

Key Content Changes - SMR

• Case studies:

– Encourage “higher-level thinking”

– Format: Short scenario descriptions followed

by probing multiple choice questions

– Cover both service and manufacturing firms

– Instructor guide explains the answers

Key Content Changes - SMR

• Six case studies covering seven topics:

– Alignment of competitive and operations strategies

– Operations strategy and performance objectives

– Quality and operations management choices

– Global competitive and operations strategy choices

– Scale, capacity, and layout effects on operations

– Quality systems and risk management/recovery

– Differentiation between order winners and qualifiers

Reference Changes - SMR

• All prior references have been replaced by new content

from selected textbook chapters and journal articles into

a sourcebook

• The sourcebook is: APICS Strategic Management of

Resources References Sourcebook, Pearson Custom

Publishing, 2009.

• An exception is the 12th edition of the APICS Dictionary,

which is not included in the sourcebook.

Reference Changes - SMR

• Textbooks:

– Slack et al., Operations and Process Management, 2nd ed.,

FTPrentice Hall, 2009

– Thompson et al., Crafting & Executing Strategy, 15th ed.,

McGraw-Hill Irwin, 2007

– Horngren et al.,, Financial and Managerial Accounting, 2nd ed.,

Prentice Hall, 2008.

– Jacobs et al., Operations and Supply Management, 2nd ed.,

McGraw-Hill Irwin, 2009.

Reference Changes - SMR

• Harvard Business Review Reprints:

– Strategy and Society: The Link Between Competitive

Advantage and Corporate Social Responsibility

– The Contradictions that Drive Toyota’s Success

– The Secrets to Successful Strategy Execution

– Leading Change: Why Transformation Efforts Fail

• Other Articles:

– EMS and Sustainable Development: A Model and

Comparative Studies of Integration

– Current Operational Practices of U.S. Small & Medium-Sized

Enterprises in Europe

– Lean Accounting and Finance

Changes to MPR,

ECO, and BSCM

2010 ECM Reference Changes

BSCM:

– BSCM reprints updated from 2006 to 2009

ECO:

– Added: Intro. to Materials Management, Arnold et al.

– Removed: Capacity Management by Blackstone

– Removed: Managerial Accounting by Garrison et al.

MPR:

– MPR reprints updated from 2007 to 2010

BSCM, ECO, MPR Changes

Course

Edits from

Instructor Log

Edits from ECM

Changes

Additional Information

BSCM

86

4

59 slides updated, 142 pages

changed

ECO

2

2

One new page on supplier

and customer service

measures; 12 pages changed

MPR

14

5

Nine slides updated, four new

slides, two new pages, 24

pages changed. Updates

include

•Logistics resource planning

•CPFR

•Transportation performance

characteristics

Recommendations for

Preparing to Teach

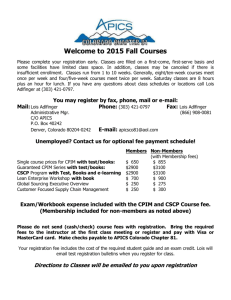

• For DSP and SMR

• Order replacement instructor kits: $150 price is good

through March 31, 2010.

• BSCM

• Order $25 update kit—price good through July 1, 2010.

• Pre-orders taken as of November 16, 2009

• Official release for all materials is December 14, 2009

Recommendations for

Preparing to Teach (cont.)

• MPR and ECO

• Download net change documents and replacement

pages at www.apics.org/InstructorCenter/CPIM/

• Downloads available December 14, 2009

• Or order $25 update kits

• All courses

• Review new 2010 ECM and references

Summary

Summary

• Extensive analysis led to 3-year update plan

• Course rewrites include a new format and improved

instructional design.

• Extensive content changes and updates were made

to DSP and SMR.

• All course content was update to correspond to the

2010 ECM.

• We gave recommendations for preparing to teach the

courses.

Acknowledgements

• DSP

– Richard Donahoue, CPIM, CSCP (Lead)

– Tom Cox, CFPIM, CSCP

– Susan Franks, CPIM, CSCP

– Tom Geraghty, CPIM

– Debra Hansford, CPIM, CIRM, CSCP, CPM, CPSM

– Ed Kantor, CPIM

– Carolyn Farr Sly, CSCP, CPIM, CPM

Acknowledgements

• SMR

– Chuck Nemer, CPI, MA-Leadership (Lead)

– Pam Somers, CPIM CIRM CSCP

– Michael Ford, CFPIM, CSCP

– Tom Geraghty, CPIM

– Richard Donahoue, CPIM, CSCP

– Tom Cox, CFPIM, CSCP

Acknowledgements

• MPR

– Michael D. Ford, CFPIM, CSCP (Lead)

– Howard Forman

• ECO

– Thomas Cox, CPIM, CSCP

– Ed Kantor, CPIM

– Rob van Stratum, CPIM CIRM, CSCP

• BSCM

– Thomas Geraghty, CPIM (Lead)

Thank you for attending this

APICS Webinar.

Be sure to visit the APICS Web site for information about

upcoming and archived presentations.

This APICS Webinar is the property of APICS,

and is protected by the United States and international

copyright laws. All rights are reserved.

Questions regarding this webinar can be emailed to

pdadmin@apics.org. Answers will be posted to the CPIM web

page within the Instructor Center. (Tawana)

To replay this webinar, visit the CPIM web page within the

Instructor Center.