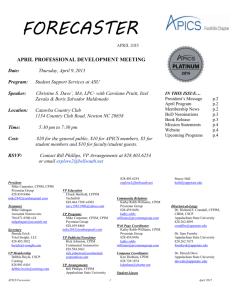

APICS July 2013 PDM Rolls Royce Presentation

advertisement

James W. Tilton CPIM Logistics Manager Global Repair Services / Americas Rolls-Royce Indianapolis Operations APICS Great Lakes District Staff Past President of APICS: Central Indiana Chapter Jim Tilton is a thirty-plus year veteran of high-tech manufacturing operations and supply chain logistics management of power systems for civilian, military, and specialty applications for use on land at sea and in the air. This includes Commercial duty automatic transmissions and gas turbine engines. His experiences range from shop floor operations to forecasting and data analysis to supply chain & logistics management for OEM, aftermarket, and component repair logistics and asset management. Jim holds a bachelors degree in Business Management from Indiana Wesleyan University, is a past President of the APICS Central Indiana Chapter and currently serves on the APICS Great Lakes District staff where is he is the program manager for the annual Great Lakes District Student Case Competition. Jim is APICS certified in Production and Inventory Management, (CPIM) and is certified to instruct CPIM Classes. He holds a Rolls-Royce Lean Six Sigma Green Belt Accreditation Other studies: Project Management Body of Knowledge (PMBOK). Recent activities: working with CONEXUS Indiana to develop the Indiana high school curriculum for advanced manufacturing and Logistics. Peter H. Clonts CPIM Master Scheduler APICS: Central Indiana Chapter Global Repair Services / Americas Vice President, Programs Rolls-Royce Indianapolis Operations Peter Clonts is a twenty-five year veteran of chemical and high-tech manufacturing operations and supply chain logistics management of power systems for civilian, military, and specialty applications for use on land, at sea, and in the air. This includes commercial duty automatic transmissions and gas turbine engines. His experiences range from production floor operations, to forecasting/planning and data analysis , to supply chain & logistics management for OEM, aftermarket, and component repair and asset management. Peter holds a bachelors degree in English from Armstrong Atlantic State University, and currently serves on the APICS Central Indiana Chapter Board of Directors He is APICS certified in Production and Inventory Management, (CPIM). Peter has won several awards for inventory management and aftermarket forecasting. He is currently completing a Rolls-Royce Lean Six Sigma Green Belt Accreditation Re-manufacturing, ‘Reverse’, and ‘Closed Loop’ Supply Chain Management • Imagine a world where: – your customers are your suppliers – your forecast is highly instable – raw material and its packaging are of questionable quality – product disposition and routings are unclear – the nature and visibility of costs and pricing are different and variable – inventory management is intentionally inconsistent and product life-cycle management is exponentially complex – used products are returned to you, not because they are broken or the wrong part, but because they are now a raw material into your operation / supply chain If (forward) Logistics is that part of the supply chain process that plans, implements, and controls the efficient, effective flow and storage of goods, services, and related information from the point-of-origin to the point-of-consumption in order to meet customers’ requirements (CLM, 1999), then Reverse Logistics is the movement of products, materials and information in the opposite direction for the purpose of creating or recapturing value, or for proper disposal (Rogers and Tibben-Lembke, 1999, 2001). This is the world of Re-manufacturing, Reverse Logistics, and Closed Loop Supply Chains. To better understand living and thriving in this world, please join Jim Tilton and Peter Clonts as they explain how Rolls-Royce embodies Reverse Supply Chain, Remanufacturing, and Recycling with aerospace engine parts.